|

CASING and TUBING INSPECTION BASICS

CASING and TUBING INSPECTION BASICS

Casing

and tubing placed in well bores may suffer from damage due to

corrosion or mechanical distress. Corrosion is caused by natural

electrical currents that flow in the earth, and from man-made

currents from power lines and surface equipment.

Corrosion can be

reduced by cathodic protection systems but not always with

perfectly satisfaction. Corrosion inspection logs and cathodic

protection evaluation logs are widely used in areas where corrosion

is known to be a problem.

Holes in tubing

or casing caused by corrosion can seriously affect production rates

and fluid composition, resulting in economic loss.

Loss of metal may

result in strength loss without holes in the pipe, allowing burst or

collapse, again with serious economic consequences. Bent, squashed,

or oval pipe can impede or prevent the passage of equipment or tools

into and out of the wellbore. Moving parts, such as pump rods, an

cause wear that eventually will cause problems if not repaired in

time.

Although most tubular goods are inspected before running into the

hole, bad pipe has been found in numerous cases after the well

completion has proved unsuccessful. Damage may also occur during

testing of the well, drilling of plugs, or well stimulation.

Un-cemented or poorly cemented casing can be damaged easily with

excessive pressure. The effect on production can be severe and

remediation will be assisted by an accurate diagnosis of the problem

by an adequate inspection program. So

there are lots of potential problems to look for.

The logs offer precise depth correlation when

recorded with gamma ray or casing collar locator logs.

The

following descriptions are condensed from the 1999 Schlumberger

Services Catalog. Equivalent logging tools are available from all

major ,and many smaller, service companies.

CASING INSPECTION with CEMENT MAPPING LOGS

CASING INSPECTION with CEMENT MAPPING LOGS

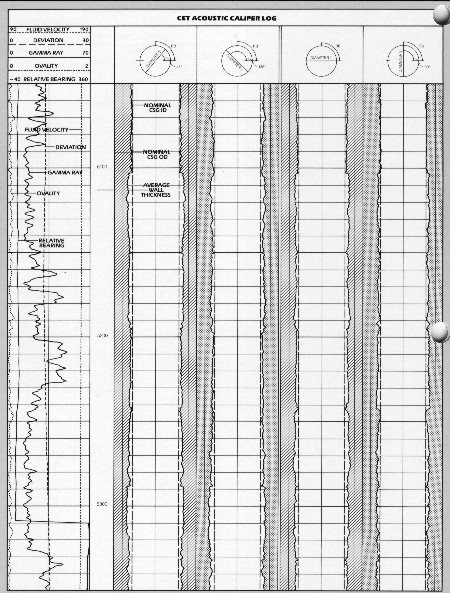

Cement evaluation tools are

traditionally used to assess cement quality, cement bond, channels,

and cement fill-up using azimuthal ultrasonic transceivers.

These tools also have a corrosion inspection mode, measuring the thickness of the casing

from its resonant

frequency. Simultaneously. the internal dimensions of the casing

are determined from the travel time of sound reflected off the

casing walls. An azimuthal image of the casing inside diameter can

be displayed.

Casing diameter, casing thickness, and ovality

logs from CET tool are use for casing inspection.

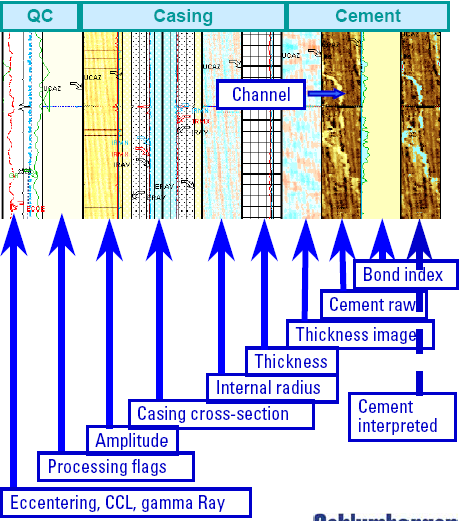

Ultrasonic imaging tools evaluate the quality of the cement and determines

both internal and

external casing corrosion. A single rotating sensor emits ultrasonic pulses and measures the resulting resonance. The USI

echo strength

and casing resonance are processed to produce detailed images of cement quality and distribution that can

spot channels as narrow as 1.2 in. Alternate presentations provide

images of casing thickness, internal radius, and internal corrosion.

Casing ovality, kinks, and holes can be observed on the image

logs. The size of the rotating head is chosen appropriately for

the size of the tubular to be surveyed.

Typical USI composite presentation with casing cross section

and internal radius measurements.

CASING and TUBING INSPECTION with ELECTROMAGNETIC LOGS

CASING and TUBING INSPECTION with ELECTROMAGNETIC LOGS

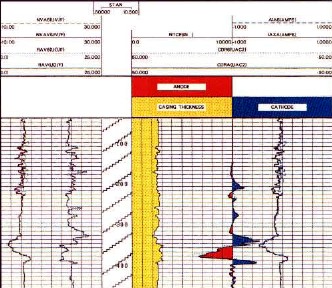

Electromagnetic

corrosion and protection evaluation tools measure casing potential and

resistance in cathodically protected wells to

evaluate protection and determine the extent of any corrosion. Using four hydraulically activated sets of

three measurement electrodes spaced at 2 foot intervals. This

service provides axial and radial current density,

corrosion rate, and casing thickness. In

wells without protection, the tool determines the rate and

location of external corrosion. Electromagnetic

corrosion and protection evaluation tools measure casing potential and

resistance in cathodically protected wells to

evaluate protection and determine the extent of any corrosion. Using four hydraulically activated sets of

three measurement electrodes spaced at 2 foot intervals. This

service provides axial and radial current density,

corrosion rate, and casing thickness. In

wells without protection, the tool determines the rate and

location of external corrosion.

This log shows

current flow in a casing string with no cathodic protection.

Corrosion is occurring at the depths shaded red.

Multi-frequency

electromagnetic

thickness tools are nondestructive and non-contact induction devices

to determine metal loss and changes in casing geometry, regardless of

fluid type. Generally used to find large scale

corrosion or casing splits, the tool also

detects metal loss in the outer casing of multiple casing

strings. A coil centered in the borehole generates an alternating magnetic field that interacts with

the casing; a second

coil measures phase shift. Multi-frequency

electromagnetic

thickness tools are nondestructive and non-contact induction devices

to determine metal loss and changes in casing geometry, regardless of

fluid type. Generally used to find large scale

corrosion or casing splits, the tool also

detects metal loss in the outer casing of multiple casing

strings. A coil centered in the borehole generates an alternating magnetic field that interacts with

the casing; a second

coil measures phase shift.

These electromagnetic measurements. made at multiple frequencies. are related

to casing wall thickness. inner diameter, and permeability / conductivity, Each

of these parameters is averaged around the pipe circumference.

This composite

corrosion log run across a lost circulation zone shows the axial and

radial currents in the casing. The log shows anodic and cathodic

sections along the casing, Anodes have developed in front of the

poorly cemented section resulting in metal loss, pits, and holes. This composite

corrosion log run across a lost circulation zone shows the axial and

radial currents in the casing. The log shows anodic and cathodic

sections along the casing, Anodes have developed in front of the

poorly cemented section resulting in metal loss, pits, and holes.

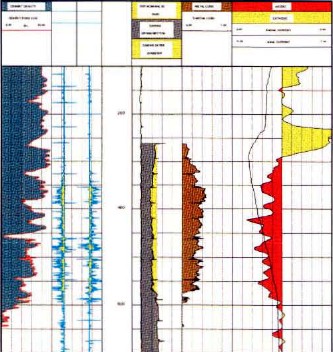

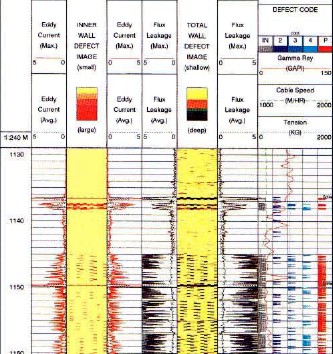

Pipe

analysis

logs monitor casing quality and discriminate

between internal and external defects. This corrosion-monitoring

service is designed primarily for detecting small holes and defects.

A high frequency eddy current test detects flaws on the inner

casing. and a magnetic flux Ieakage test inspects the full casing

thickness. With these measurements. small defects and corroded areas

in pipe are detected. and defects on the inner and outer walls of a

single casing string can he identified. Twenty-four sensor signals (12

flux

and 12 eddy) are digitally recorded for complete surface processing.

When combined with other services. severe corrosion and defects can

be detected and identified on the inner or outer pipe in a double

casing string. Pipe

analysis

logs monitor casing quality and discriminate

between internal and external defects. This corrosion-monitoring

service is designed primarily for detecting small holes and defects.

A high frequency eddy current test detects flaws on the inner

casing. and a magnetic flux Ieakage test inspects the full casing

thickness. With these measurements. small defects and corroded areas

in pipe are detected. and defects on the inner and outer walls of a

single casing string can he identified. Twenty-four sensor signals (12

flux

and 12 eddy) are digitally recorded for complete surface processing.

When combined with other services. severe corrosion and defects can

be detected and identified on the inner or outer pipe in a double

casing string.

PAL log recorded

to evaluate casing corrosion. Perforations are at 1145 to 1160 ft,

and perforations that have been squeeze cemented are at 1165 to 1167

and to 1190 fl.

fs

CASING and TUBING INSPECTION with MULTI-FINGER CALIPERS

CASING and TUBING INSPECTION with MULTI-FINGER CALIPERS

Tubing

geometry logs are multi-finger calipers, used to precisely measure variations in

the internal diameter of the tubing and to provide data for collar

corrosion analysis. The spherical lips of the caliper~ exert only 2

kg of contact force, thereby avoiding damage to pipe coatings.

Interchangeable fingers permit corrosion monitoring over a

wide range of tubing sizes. Each set of feelers can be opened and

closed downhole for repeat passes over the zone of interest. Each

of the 16 sensors generates an independent signal recorded versus

depth and both well site and computed products are available. Tubing

geometry logs are multi-finger calipers, used to precisely measure variations in

the internal diameter of the tubing and to provide data for collar

corrosion analysis. The spherical lips of the caliper~ exert only 2

kg of contact force, thereby avoiding damage to pipe coatings.

Interchangeable fingers permit corrosion monitoring over a

wide range of tubing sizes. Each set of feelers can be opened and

closed downhole for repeat passes over the zone of interest. Each

of the 16 sensors generates an independent signal recorded versus

depth and both well site and computed products are available.

Multi-finger tubing caliper

with grey scale caliper map - white is 4.0 inches, black is 4.5

inches. Multi-finger tubing caliper

with grey scale caliper map - white is 4.0 inches, black is 4.5

inches.

Multi-finger casing caliper logs

are mechanical casing inspection devices.

Using from 36 to 72 fingers. depending on the diameter to be

measured. The tool gives very high resolution, radially and

vertically, to identify casing corrosion ranging from small pits and

scale to axial splits. The tool can be opened and closed downhole. Radii measurements include three minimum

and three

maximum (one each per 120-degree section) or six maximum (one each

per 60-degree section). All raw data and computations are available

at the well site.

CASE HISTORY: CASING INSPECTION

CASE HISTORY: CASING INSPECTION

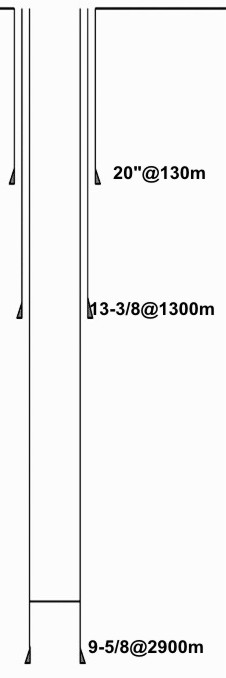

This

example combines both cement integrity and casing integrity issues.

The problem is to determine where a water flow behind casing is

coming from. The first thing you need is a a well diagram to see

what plumbing is in place, as shown at the right. The water flow is

coming up between the 9-5/8 and 13-3/8 inch casing strings. The only

water can get there is through poor quality cement behind the 9-5/8"

casing OR through a leak in the 13-3/8" casing combined with poor

cement behind that casing string. This

example combines both cement integrity and casing integrity issues.

The problem is to determine where a water flow behind casing is

coming from. The first thing you need is a a well diagram to see

what plumbing is in place, as shown at the right. The water flow is

coming up between the 9-5/8 and 13-3/8 inch casing strings. The only

water can get there is through poor quality cement behind the 9-5/8"

casing OR through a leak in the 13-3/8" casing combined with poor

cement behind that casing string.

Well diagram

showing casing sizes and depths

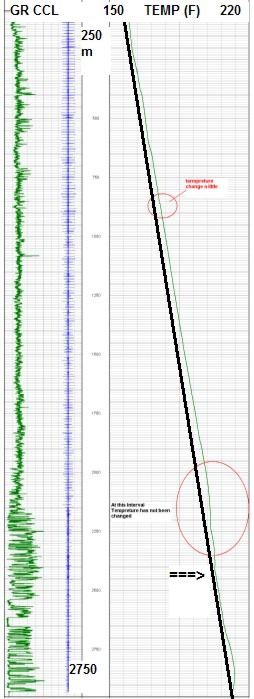

The

cheapest logs to check for water flow are noise logs and temperature

logs. In this well a temperature log was run. Water inflow might

show a slight low temperature at the point of entry, caused by gas

released from solution, with a small high temperature anomaly above

geothermal gradient, as the warm water moves upward through cooler

horizons. This water flow is 100 bbl/day, so it is significant

enough to cause such an anomaly. The

cheapest logs to check for water flow are noise logs and temperature

logs. In this well a temperature log was run. Water inflow might

show a slight low temperature at the point of entry, caused by gas

released from solution, with a small high temperature anomaly above

geothermal gradient, as the warm water moves upward through cooler

horizons. This water flow is 100 bbl/day, so it is significant

enough to cause such an anomaly.

Compressed vertical scale

temperature log. Dark diagonal line is a constant gradient. Coolest

temperature is at large arrow, with a warm spot above it (circled)

reverting to geothermal gradient above suspected entry point. Compressed vertical scale

temperature log. Dark diagonal line is a constant gradient. Coolest

temperature is at large arrow, with a warm spot above it (circled)

reverting to geothermal gradient above suspected entry point.

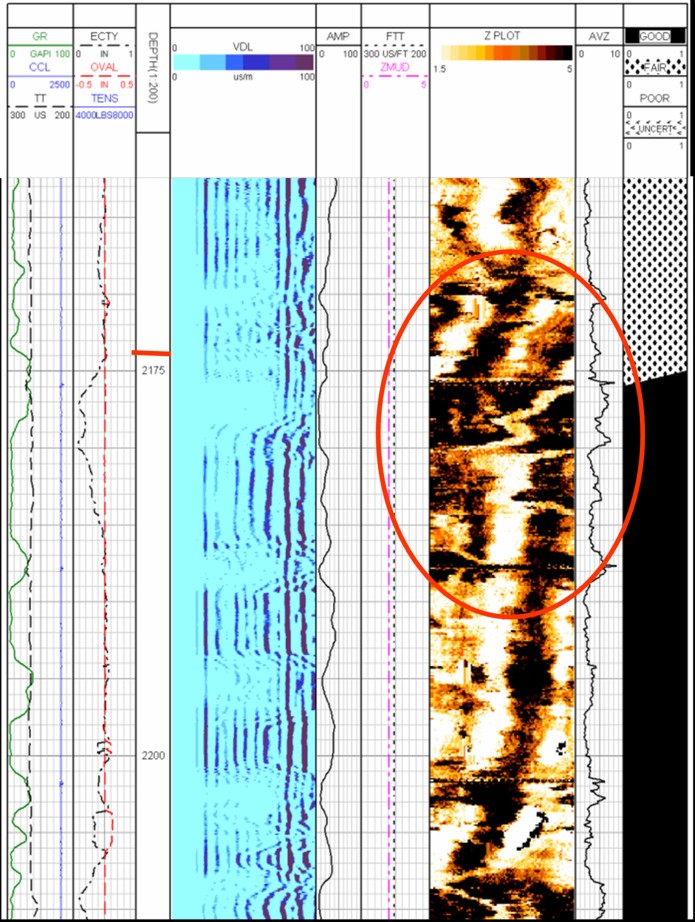

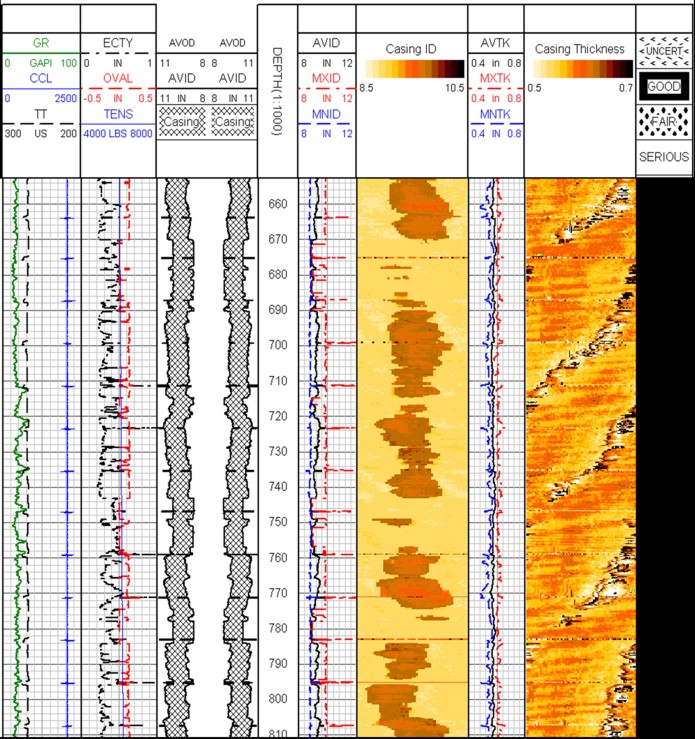

The illustration below is a casing inspection log showing good

casing at this depth. The casing ID and OD are normal and the map

shows no breaks or holes. Since water is not entering this casing

string, the log merely confirms our understanding of the situation.

Below that is an illustration of the cement integrity log, showing a

large cement channel with only about 50% of the annulus filled with

cement. While the cement is well bonded, it does not provide

isolation, and this problem persists throughout the well bore.

A cement squeeze to

fill this channel is needed. The interval should be re-logged after

the squeeze to verify isolation and fill up of the annulus.

Casing inspection log over suspect area shows good casing. Ignore

the cement quality indicator on the right edge - it is just plain

WRONG - see below.

Cement integrity log over suspect interval shows a bad cement job.

White on cement map is a channel and black is good cement., giving a

Bond Index of only 50%. Water can easily flow up through such a

channel. The cement quality flag at the extreme right is WRONG

(black is supposed to represent good cement but the trigger level is

not set correctly - you need at least 80 to 90% bond for isolation

to water.

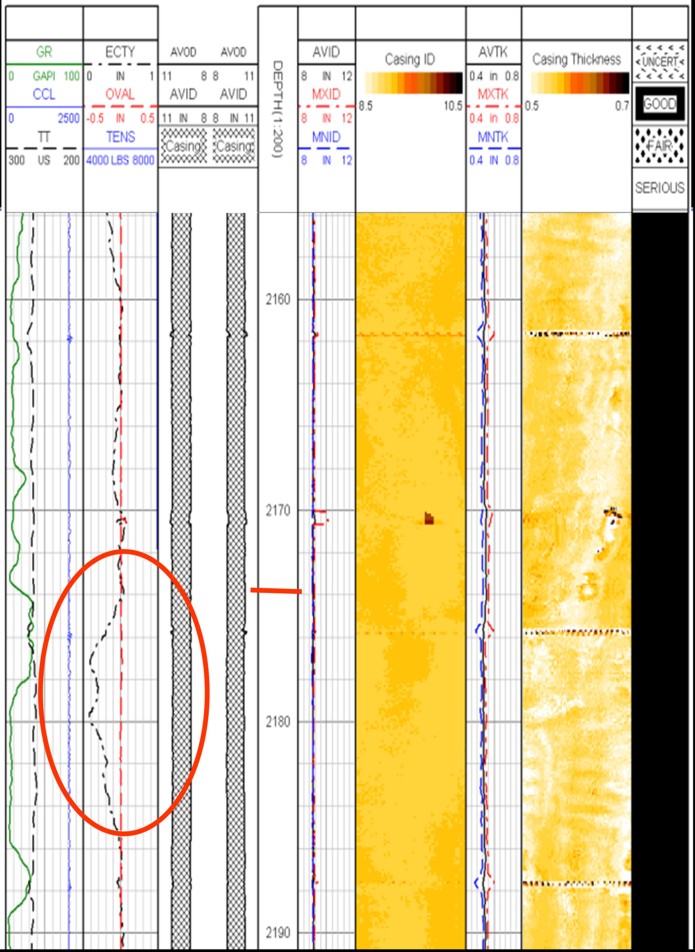

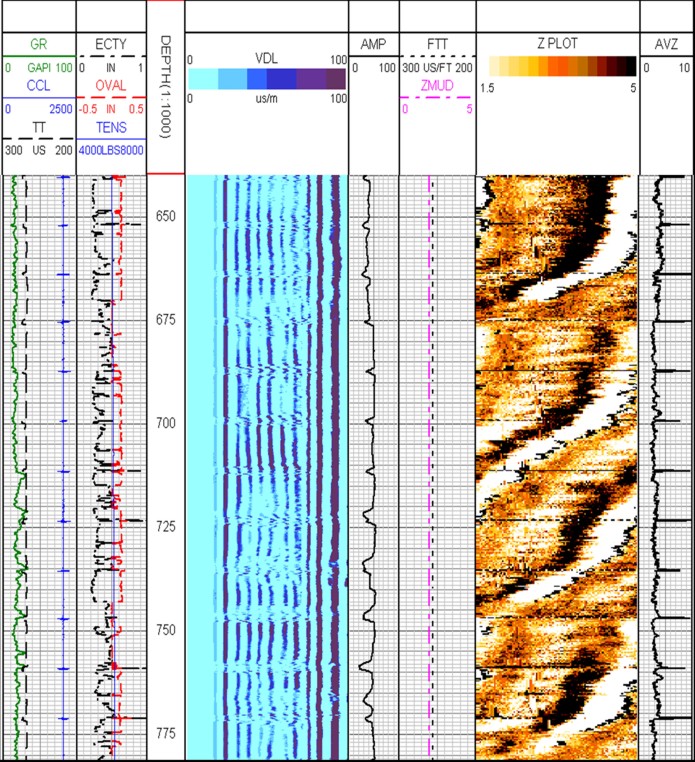

This may not be the end of the

story. The integrity of the intermediate casing also needs to be

checked. Fortunately, casing and cement logs were run before the

well was drilled to total depth. Samples are shown below. Lots of

corrosion both inside and outside the casing is indicated, possibly

because this was re-used casing. Kinks and dents are also evident on

the casing ID map. The cement fill up is also poor and a remedial

squeeze job should have been performed before the well was deepened.

There is one anomaly on the casing that might indicate a split (see

below.. There is no easy way to squeeze behind this casing now and

the temperature log is too insensitive to confirm a water leak at

this depth. The salinity of the water flowing in the annulus might

provide a clue as to whether the water is coming from a deep or

shallow source.

Casing profile shows corrosion an inside and outside of pipe. Map of

inside diameter shows casing is oval - dark red is large diameter,

pale colour is small diameter. Casing thickness shows possible

splits (white diagonal areas with dark blobs- white is thin, black

is thick). "Good" cement flag at far right is not correct - see

image below.

Cement bond and cement map show poor bond with a medium size channel

and no bond to the formation If the casing is split as indicated in

the previous image, this cement could allow water inflow between

this casing string and the liner. Note that the apparent "casing

splits" on the casing log are at the same place as the missing

cement. The interpretation of a casing split here is not certain -

an electromagnetic pipe evaluation tool would have been needed to

confirm.

|