|

CEMENTING

BASICS

CEMENTING

BASICS

Cement

bond logs were run as early as 1958 with early sonic logs and the

temperature log was used to find cement top beginning in 1933.

Cement integrity logs are run to determine the quality of the

cement bond to the production casing, and to evaluate cement fill-up

between the casing and the reservoir rock. A poor cement bond

may allow unwanted fluids to enter the well. Poor fill-up of cement

leaves large channels behind the pipe that, likewise, allow the

flow of unwanted fluids, such as gas or water into an oil well.

By-products of cement integrity logs are the compressive strength

of the cement, the bond index, and in some cases, the quality

of the casing string itself.

Both

poor bond and poor fill-up problems can also allow fluids to flow

to other reservoirs behind casing. This can cause serious loss

of potential oil and gas reserves, or in the worst case, can cause

blowouts at the wellhead. Unfortunately, in the early days of

well drilling, cement was not required by law above certain designated

depths. Many of the shallow reservoirs around the world have been

altered by pressure or fluid crossflow from adjacent reservoirs

due to the lack of a cement seal.

Getting

a good cement job is far from trivial. The drilling mud must be

flushed out ahead of the cement placement, the mud cake must be

scraped off the borehole wall with scratchers on the casing, fluid

flow from the reservoir has to be prevented during the placement

process, and the casing has to be centralized in the borehole.

Further, fluid and solids loss from the cement into the reservoir

has to be minimized.

Gas

percolation through the cement while it is setting is a serious

concern, as the worm holes thus created allow high pressure gas

to escape up the annulus to the wellhead - a very dangerous situation.

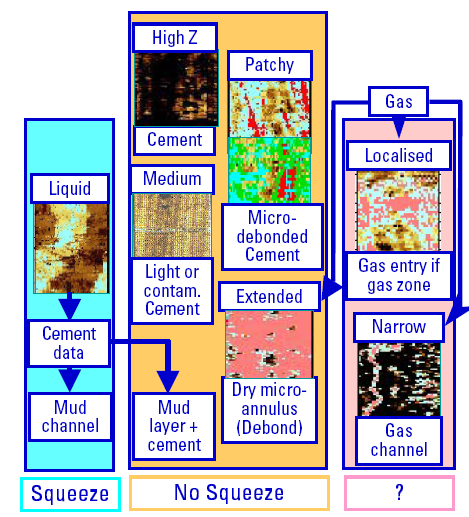

Poor

bond or poor fill-up can often be repaired by a cement squeeze,

but it is sometimes impossible to achieve perfect isolation between

reservoir zones. Gas worm holes are especially difficult to seal

after they have been created.

Poor

bond can be created after an initial successful cement job by

stressing the casing during high pressure operations such as high

rate production or hydraulic fracture stimulations. Thus bond

logs are often run in the unstressed environment (no pressure

at the wellhead) and under a stressed environment (pressure at

the wellhead).

Cement

needs to set properly before a cement integrity log is run. This

can take from 10 to 50 hours for typical cement jobs. Full compressive

strength is reached in 7 to 10 days. The setting time depends

on the type of cement, temperature, pressure, and the use of setting

accelerants. Excess pressure on the casing should be avoided during

the curing period so that the cement bond to the pipe is not disturbed.

Cement Integrity Log

Basics Cement Integrity Log

Basics

Today’s

cement integrity logs come in four flavours: cement bond logs

(CBL), cement mapping logs (CMT), ultrasonic cement mapping tools

(CET), and ultrasonic imaging logs (USI, RBT). Examples and uses

for each are described in this Chapter.

Before

the invention of sonic logs, temperature logs were used to locate

cement top, but there was no information about cement integrity.

Some knowledge could be gained by comparing open hole neutron

logs to a cased hole version. Excess porosity on the cased hole

log could indicate poor fill-up (channels) or mud contamination.

The neutron log could sometimes be used to find cement top.

The

earliest sonic logs appeared around 1958 and their use for cement

integrity was quantified in 1962. The sonic signal amplitude was

the key to evaluating cement bond and cement strength. Low signal

amplitude indicated good cement bond and high compressive strength

of the cement.

In

the 1970’s, the segmented bond tool appeared. It uses 8

or more acoustic receivers around the circumference of the logging

tool to obtain the signal amplitude in directional segments. The

average signal amplitude still gives the bond index and compressive

strength, but the individual amplitudes are shown as a cement

map to pinpoint the location of channels, contamination, and missing

cement. This visual presentation is easy to interpret and helps

guide the design of remedial cement squeezes. An ultrasonic version

of the cement mapping tool also exists. The log presentation is

similar to the segmented bond log, but the measurement principle

is a little different.

Another

ultrasonic tool uses a rotating acoustic transducer to obtain

images for cement mapping. It is an offshoot of the open hole

borehole televiewer. The signal is processed to obtain the acoustic

impedance of the cement sheath and mapped to show cement quality.

The tool indicates the presence of channels with more fidelity

than the segmented bond tool and allows for analysis of foam and

extended cements.

Individual

acoustic reflections from the inner and outer pipe wall give a

pipe thickness log, helpful in locating corrosion, perforations,

and casing leaks.

Temperature Logs for Cement Top Temperature Logs for Cement Top

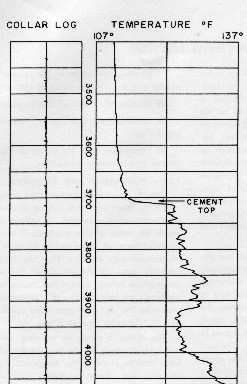

In

the “good old days” before the invention of sonic

logs, there was no genuine cement integrity log. However, the

location of the cement top was often required, either to satisfy

regulations or for general knowledge. Since cement gives off heat

as it cures, the temperature log was used to provide evidence

that the well was actually cemented to a level that met expectations.

An example is shown at right. The top of cement is located

where the temperature returns to geothermal gradient. The log

must be run during the cement curing period as the temperature

anomaly will fade with time. In

the “good old days” before the invention of sonic

logs, there was no genuine cement integrity log. However, the

location of the cement top was often required, either to satisfy

regulations or for general knowledge. Since cement gives off heat

as it cures, the temperature log was used to provide evidence

that the well was actually cemented to a level that met expectations.

An example is shown at right. The top of cement is located

where the temperature returns to geothermal gradient. The log

must be run during the cement curing period as the temperature

anomaly will fade with time.

Today,

most wells are cemented to surface to protect shallow horizons

from being disturbed by crossflows behind pipe. In this case,

cement returns to surface are considered sufficient evidence for

a complete cement fill-up.

Cement Bond Logs (CBL) Cement Bond Logs (CBL)

Cement

bond logs (CBL) are still run today because they are relatively

inexpensive and almost every wireline company has a version of

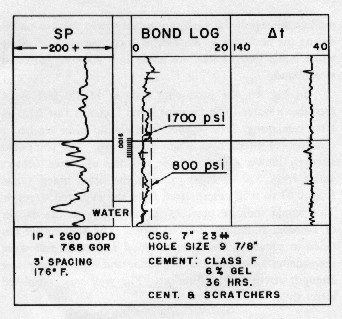

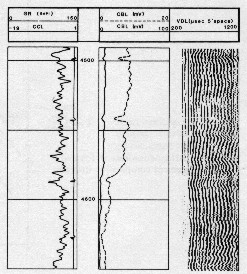

the tool. The log example at the right illustrates the use of

the acoustic amplitude curve to indicate cement bond integrity. Cement

bond logs (CBL) are still run today because they are relatively

inexpensive and almost every wireline company has a version of

the tool. The log example at the right illustrates the use of

the acoustic amplitude curve to indicate cement bond integrity.

The

examples in this Section are taken from ”Cement Bond Log

Interpretation of Cement and Casing Variables”, G.H. Pardue,

R.L. Morris, L.H. Gallwitzer, Schlumberger 1962.

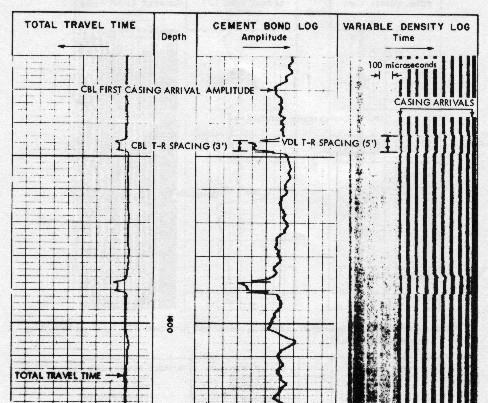

EXAMPLE 1: CBL in well bonded cement – low amplitude means good

bond. The SP is from an openhole log; a gamma ray curve is more

common. Most logs run today have additional computed curves, as

well as a VDL display of the acoustic waveforms.

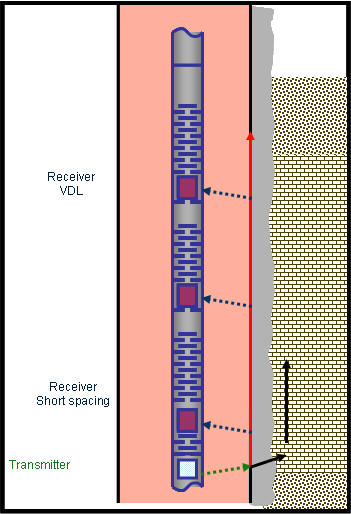

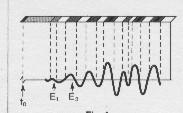

The CBL uses conventional sonic log principals of refraction to

make its measurements. The sound travels from the transmitter,

through the mud, and refracts along the casing-mud interface and

refracts back to the receivers, as shown in the illustration on

the left. In fast formations (faster than the casing), the signal

travels up the cement-formation interface, and arrives at the

receiver before the casing refraction. The CBL uses conventional sonic log principals of refraction to

make its measurements. The sound travels from the transmitter,

through the mud, and refracts along the casing-mud interface and

refracts back to the receivers, as shown in the illustration on

the left. In fast formations (faster than the casing), the signal

travels up the cement-formation interface, and arrives at the

receiver before the casing refraction.

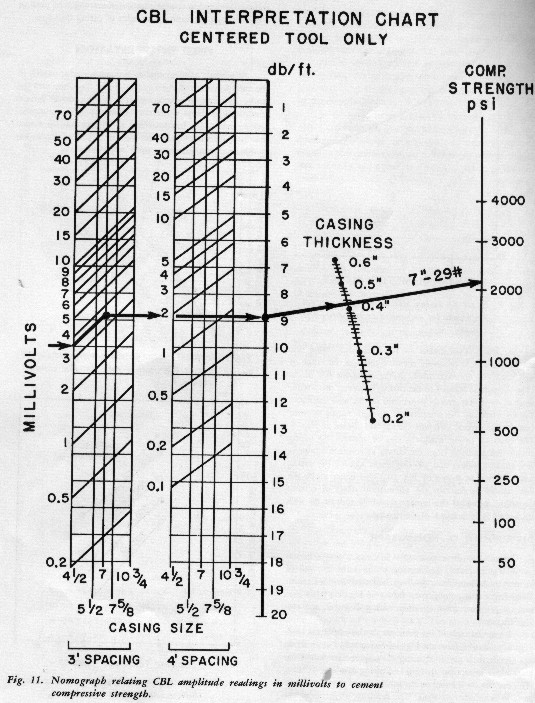

The

amplitude is recorded on the log in millivolts, or as attenuation

in decibels/foot (db/ft), or as bond index, or any two or three

of these. A travel time curve is also presented. It is used as

a quality control curve. A straight line indicates no cycle skips

or formation arrivals, so the amplitude value is reliable. Skips

may indicate poor tool centralization or poor choice for the trigger

threshold.

The

actual value measured is the signal amplitude in millivolts. Attenuation

is calculated by the service company based on its tool design,

casing diameter, and transmitter to receiver spacing. Compressive

strength of the cement is derived from the attenuation with a

correction for casing thickness. Finally, bond index is calculated

by the equation:

1:

BondIndex = Atten / ATTMAX

Where:

Atten

= Attenuation at any point on the log (db/ft or db/meter)

ATTMAX

= Maximum attenuation (db/ft or db/meter)

The

maximum attenuation can be picked from the log at the depth where

the lowest amplitude occurs. On older logs attenuation and bond

index were computed manually. On modern logs, these are provided

as normal output curves. Bond Index is a qualitative indicator

of channels. A Bond Index of 0.30 suggests that only about 30%

of the annulus is filled with good cement.

INTERPRETATION

RULE 1: Low Amplitude = Good Cement

INTERPRETATION RULE 2: High Attenuation = Good Cement

INTERPRETATION RULE 3: High Bond Index = Good Cement

|

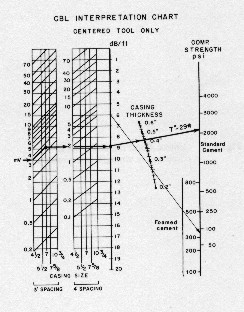

A

nomograph for calculating attenuation and bond index for older

Schlumberger logs is given below.

Chart for calculating cement bond attenuation

and cement compressive strength

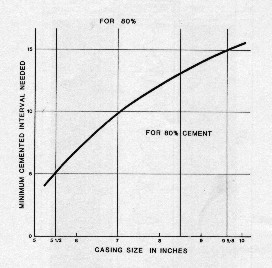

Zone

isolation is a critical factor in producing hydrocarbons. In oil

wells, we want to exclude gas and water; in gas wells, we want

to exclude water production. We also do not want to lose valuable

resources by crossflow behind casing. Isolation can reasonably

be assured by a bond index greater than 0.80 over a specific distance,

which varies with casing size. Experimental work has provided

a graph of the interval required, as shown at the left. Zone

isolation is a critical factor in producing hydrocarbons. In oil

wells, we want to exclude gas and water; in gas wells, we want

to exclude water production. We also do not want to lose valuable

resources by crossflow behind casing. Isolation can reasonably

be assured by a bond index greater than 0.80 over a specific distance,

which varies with casing size. Experimental work has provided

a graph of the interval required, as shown at the left.

The

following examples illustrate the basic interpretation concepts

of cement bond logs. Note that log presentations as clean and

simple as this are no longer available, but these are helpful

in showing the basic concepts. The

following examples illustrate the basic interpretation concepts

of cement bond logs. Note that log presentations as clean and

simple as this are no longer available, but these are helpful

in showing the basic concepts.

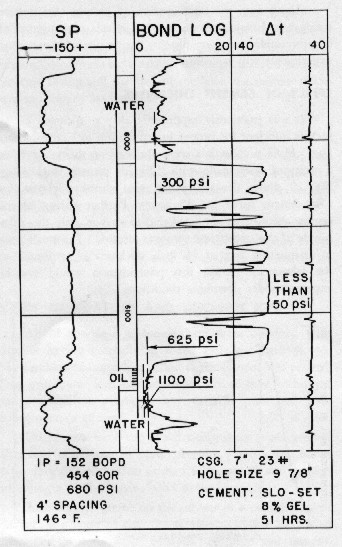

EXAMPLE 2: CBL with both good and bad cement; hand calculated compressive

strength shown by dotted lines, labeled in psi; SP from openhole

log. Note straight line on travel time curve and bumps indicating

casing collars.

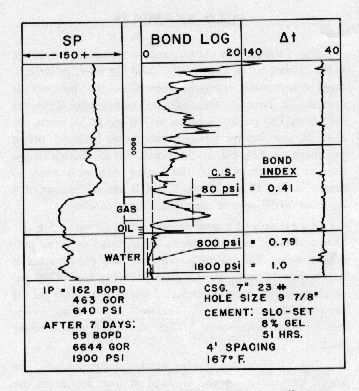

EXAMPLE

3: This log shows good bond over the oil and water zones,

but poor cement over the gas zone, probably due to percolation

of gas into the cement during the curing process. The worm holes

are almost impossible to squeeze and this well may leak gas to

surface through the annulus for life, because the bond is poor

everywhere above the gas. A squeeze job above the gas may shut

off any potential hazard. EXAMPLE

3: This log shows good bond over the oil and water zones,

but poor cement over the gas zone, probably due to percolation

of gas into the cement during the curing process. The worm holes

are almost impossible to squeeze and this well may leak gas to

surface through the annulus for life, because the bond is poor

everywhere above the gas. A squeeze job above the gas may shut

off any potential hazard.

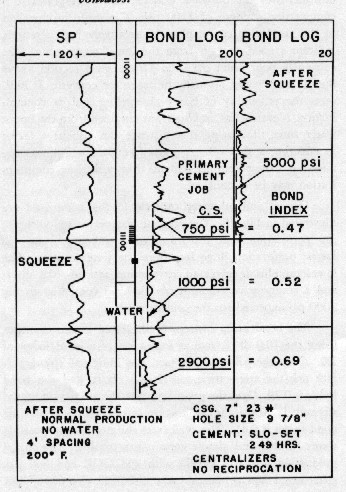

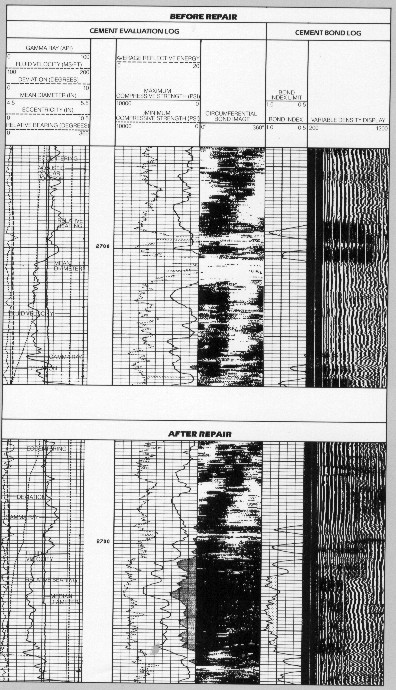

EXAMPLE

4: Cement bond log before and after a successful cement squeeze.

Even though modern logs contain much more information than these

examples, the basics have not changed for 40 years. EXAMPLE

4: Cement bond log before and after a successful cement squeeze.

Even though modern logs contain much more information than these

examples, the basics have not changed for 40 years.

Cement Bond Logs with

Variable Density Display (CBL-VDL) Cement Bond Logs with

Variable Density Display (CBL-VDL)

While the important results of a CBL are easily seen on a conventional

CBL log display, such as signal amplitude, attenuation, bond index,

and cement compressional strength, an additional display track

is normally provided. This is the variable density display (VDL)

of the acoustic waveforms. They give a visual indication of free

or bonded pipe (as do the previously mentioned curves) but also

show the effects of fast formations, decentralized pipe, and other

problems.

But

you need really good eyes and a really good display to do this.

The display is created by transforming the sonic waveform at every

depth level to a series of white-grey-black shades that represent

the amplitude of each peak and valley on the waveform. Zero amplitude

is grey, negative amplitude is white, and positive amplitude is

black. Intermediate amplitudes are supposed to be intermediate

shades of grey. But

you need really good eyes and a really good display to do this.

The display is created by transforming the sonic waveform at every

depth level to a series of white-grey-black shades that represent

the amplitude of each peak and valley on the waveform. Zero amplitude

is grey, negative amplitude is white, and positive amplitude is

black. Intermediate amplitudes are supposed to be intermediate

shades of grey.

This

seldom happens because the display is printed on black and white

printers that do not recognize grey. Older logs were displayed

to film that did not have a grey – only black or clear (white

when printed). So forget the grey scale and look for the patterns.

Older logs were analog – the wavetrain was sent uphole as

a varying voltage on the logging cable. These logs could not be

re-displayed to improve visual effects. Modern logs transmit and

record digitized waveforms that can be processed or re-displayed

to enhance their appearance.

The

examples below show the various situations that the VDL is supposed

to elucidate. These examples are taken from “New Developments

in Sonic Wavetrain Display and Analysis in Cased Holes”,

H.D. Brown, V.E. Grijalva, L.L. Raymer, SPWLA 1970.

INTERPRETATION

RULE 1: Low Amplitude = Good Cement

INTERPRETATION RULE 2: High Attenuation = Good Cement

INTERPRETATION RULE 3: High Bond Index = Good Cement

EXCEPT WHEN FAST FORMATION ARRIVALS APPEAR

|

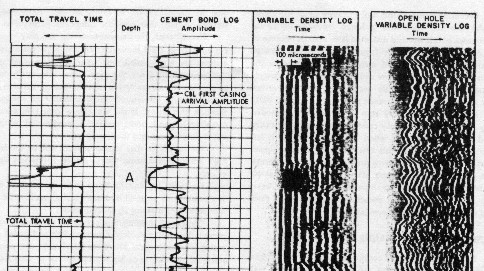

EXAMPLE 5: CBL-VDL in free pipe (no cement). Notice straight

line and high amplitude pattern on VDL pipe arrivals (railroad

track pattern). Travel Time curve is constant and amplitude curve

reads high. Note casing collar anomalies on travel time and amplitude

curves, and more weakly on VDL display.

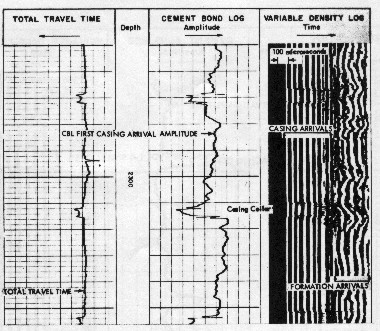

EXAMPLE 6: Casing is still unbonded (high amplitude railroad

tracks on early arrivals on VDL), amplitude curve reads high,

BUT late arrivals on VDL have “shape” and track porosity

log shape. This indicates free pipe laying on side of borehole

and touching formation. The VDL arrivals with “shape”

are the formation arrivals. Better casing centralization should

be used on the next well. A cement squeeze will improve the scene

but will probably not provide isolation on the low side of the

pipe.

EXAMPLE 7: Well bonded pipe (low amplitude on early arrivals

on VDL, good bond to formation (high amplitude late arrivals with

“shape”). Mud arrivals would have high amplitude but

no “shape”.

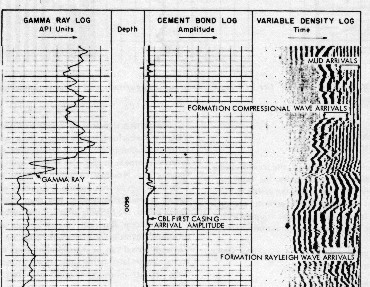

EXAMPLE 8: At Zone A, amplitude shows good bond, but VDL

shows low amplitude formation signal. This indicates poor bond

to formation. Travel time curve reads very high compared to baseline,

indicating cycle skipping on casing arrivals – but casing

bond is still good. Travel time less than base line value would

indicate fast formation. If you can detect fast formations, bond

is still good, regardless of high early arrival amplitude.

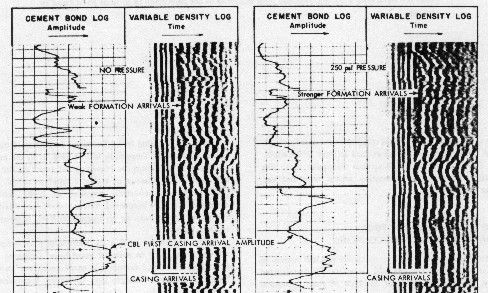

EXAMPLE 9: VDL on left shows poor bond but formation signal

is fairly strong. When casing is put under pressure, bond improves

(not a whole lot) as seen on lower amplitude early arrivals on

right hand log. This is called a micro-annulus. Under normal oil

production, the micro-annulus is not too big a problem unless

bottom hole pressure is very low. Micro-annulus is caused by dirty

or coated pipe, pressuring casing before cement is fully cured,

or ridiculous pressures applied during stimulation.

EXAMPLE 10: When there is no CBL-VDL made under pressure,

the un-pressured version can be used to interpret micro-annulus.

High amplitude early arrivals (normally indicating poor bond)

actually indicate good bond (with micro-annulus) IF formation

signals are also strong.

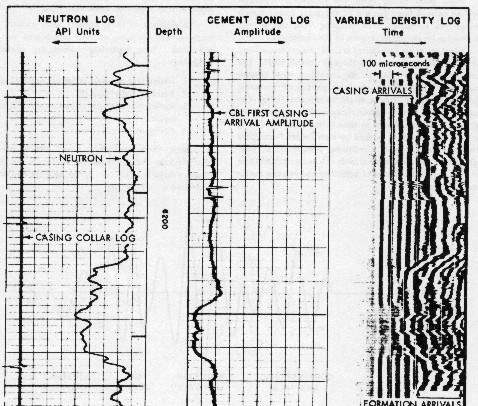

EXAMPLE 11: The travel time curve is lower than baseline (shaded

areas, Track 1) indicating fast formation arrivals. If you see

fast formation, you have a good bond to pipe and to formation.

However, you cannot use the amplitude curve (labeled “Casing

Bond” on this example) to calculate attenuation, compressive

strength, or bond index, because the amplitude is measured on

the formation arrivals, not the pipe arrivals.

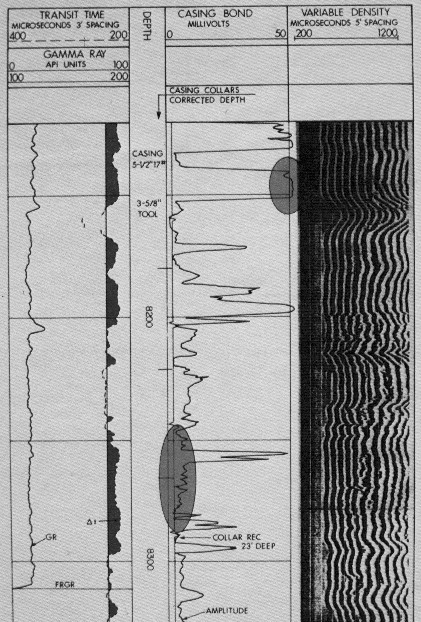

EXAMPLE 12: CBL-VDL shows the transition from normal to

foam cement just above 4650 feet. The foam cement has lower compressive

strength so the amplitude curve shifts to the right. Notice the

use of the expanded amplitude scale (0 to 20 mv) to accentuate

the change. The compressive strength is computed from a different

algorithm than normal cement, shown in the nomograph in below.

Nomograph for calculating compressive strength in normal and

foam cement.

Note

foam cement values on lower left side of compressive strength

scale.

Cement Mapping Tools (CET, PET, CMT)

Cement Mapping Tools (CET, PET, CMT)

Cement

evaluation (CET) and cement mapping (CMT) tools continue to use many

of the features of cement bond (CBL) logs, but add a new feature - a

circumferential image representing the cement quality, or lack of

it. The ultrasonic imaging (USI) tool, an offshoot of the openhole

acoustic image log, is the most recent version of this class.

The CET uses conventional sonic log principles, with measurements

made parallel to the tool axis, with 6 or 8 segmented transmitter

receiver sets spaced radial around the tool. CMT tools use an

ultrasonic pulse echo system, measuring radially, again with 6 or 8

radially spaced transducers. USI type tools use a rotating head,

pulse echo concept.

Classical cement bond (CBL) logging tools measure the amplitude

or attenuation of 20 to 30 kHz acoustic pulses propagating axially

along the casing between a single transmitter and a single receiver.

There

are three types of cement mapping tools. The CMT operates with

the same acoustic principles as the CBL, but uses oriented acoustic

receivers to recover amplitude data from 6, 8 , or ten radial

directions (depending on tool design). They may use a single transmitter

or one transmitter for each receiver. Some of these tools are

pad-type devices.

The

second type, the cement evaluation tool (CET) uses ultrasonic

acoustic pulses and measures radially instead of axially. This

tool is described later in this Section. A third type of cement

mapping tool, the rotating-head bond log (RBT) or ultrasonic imaging

log (USI) is described in the next Section.

On

a CMT, the average amplitude curve is used in the same manner

as a CBL to obtain attenuation, bond index, and cement compressive

strength. A cement map is made from the amplitude of the individual

receivers, to locate channels and voids in the cement.

These

logs are sometimes referred to generically as segmented cement

bond logs.

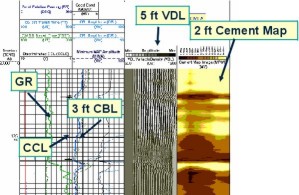

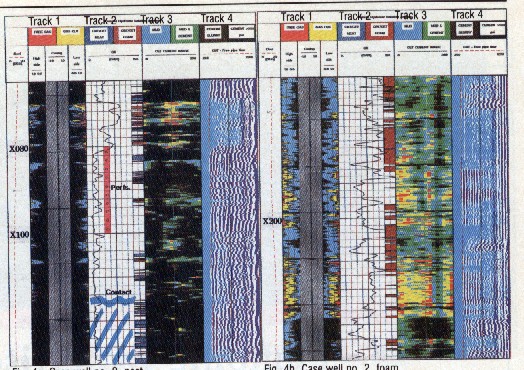

CBL-CMT log example

The

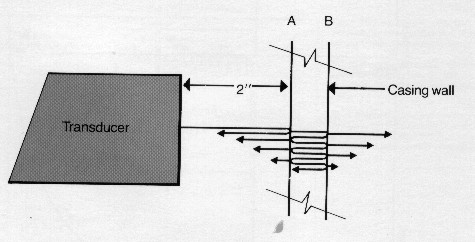

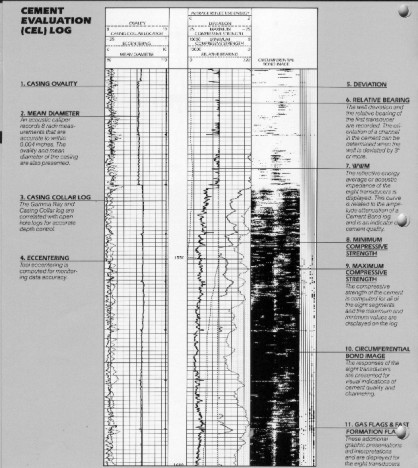

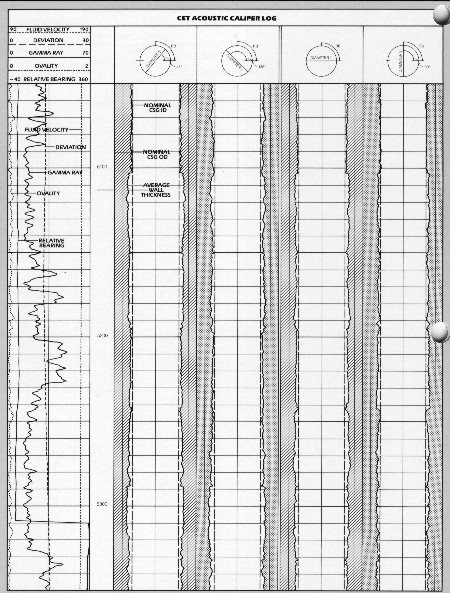

cement evaluation tool (CET) tool investigates the cement radially

instead of axially. Eight ultrasonic transducers, operating as

both transmitters and receivers, are positioned radially around

the CET sonde 45 degrees apart. Each transducer emits a beam of

ultrasonic energy in a 300 to 600 kHz band, which covers the resonant

frequency range of most oilfield casing thicknesses. These tools

are also called pulse echo tools (PET).

CET

log presentations look similar to the CMT, but casing diameter

and other information is obtained by processing the echo signal.

The pulse echo concept is illustrated below.

Sound paths for pulse echo (CET) type cement

bond log

The

energy pulse causes the casing to ring or resonate in its thickness

dimension, as shown above, perpendicular to the casing

axis. The vibrations die out quickly or slowly, depending on the

material behind the casing. The majority of the energy is reflected

back to the transducer where it is measured, and the remainder

passes into the casing wall and echoes back and forth until it

is totally attenuated.

Each

time the pulse is reflected off the inner casing wall, some energy

passes through the interface and reaches the transducer. A ninth

transducer continually measures acoustic travel time of the casing

fluid column so that the other eight transducer travel times can

be converted to distance measurements. This fluid travel time

can be presented on the log, if desired, to indicate the type

of casing fluid.

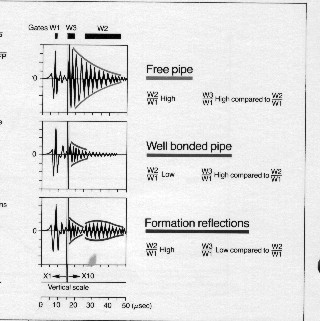

CET

logs record attenuation of the acoustic signal directly by computing

the decay of energy on each waveform by comparing the energy in

an early-time window W1 and a later-time window W2, as shown

below.

Reflection waveforms and measurement gates for CET calculations

INTERPRETATION

RULE 1: Low Amplitude = Good Cement

INTERPRETATION RULE 2: High Attenuation = Good Cement

INTERPRETATION RULE 3: High Bond Index = Good Cement

INTERPRETATION RULE 4: High Compressive Strength = Good

Cement |

Minimum

and maximum compressive strength are computed from the minimum

and maximum attenuations on the 8 transducers. These are displayed

as continuous log curves. The cement map is created from the energy

of the early arrivals of the acoustic waveform in the 8 radial

directions. A gas flag is generated when late arrivals are very

low energy and a fast formation flag is generated when late arrivals

are high energy.

The

tool can be oriented to the low side of the borehole or to true

north. In addition, measurements of casing diameter, casing roundness,

and tool eccentering are derived from the arrival times of the

8 transducers. These caliper curves show casing wear, corrosion,

or collapse.

Experience

has shown that when there is good cement around the pipe, the

bond to the formation is usually good, too. When the cement sheath

is very thin, the CET tool responds to formation arrivals. However,

when the cement is thick the formation reflections may be too

small to measure. So, if good pipe bond but bad formation bond

is suspected, the best interpretation can be made by combining

the Cement Evaluation log with the Cement Bond/Variable Density

log.

eXAMPLES

eXAMPLES

Layout of CET log. The important curves are

the attenuation and compressive strength values

in Track 2 and

the cement map in Track 3. Other data is annotated on the side

of the plot.

CET with CBL-VDL before and after squeeze. Note

improved cement map, higher

compressive strength, and formation

signal on VDL.

Casing diameter, casing thickness, and ovality

logs from CET tool are use for casing inspection.

Data from CBL-VDL and CET are combined in Schlumberger’s

Cement Advisor program to

generate a more informative cement map

and zone isolation flags (Track 2) in both neat and

foam cement.

A section of well with neat cement is shown at left and a section

of foam cement

on the right. Track 1 contains colour coded cement

volume map and Track 3 shows a

computed cement impedance map.

The colour code is dark for good cement shading to

yellow for

gas (nitrogen in the case of foam cement). Colour code thresholds

vary from job to job.

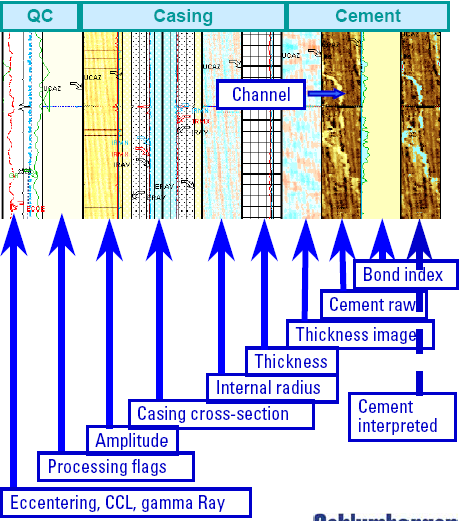

Ultra Sonic Image Logs (USI, RBT)

Ultra Sonic Image Logs (USI, RBT)

The USI Ultra Sonic Imager and UBI Ultrasonic Borehole Imager

tools are acoustic borehole imaging logs. The USI is a cased

hole cement bond / cement mapping tool with output similar to

the CET, but with more complete coverage of the borehole. The

UBI is an openhole tool for formation imaging. They are physically

similar to each other but use different transducers. This tool

type is sometimes referred to as a rotating-head bond tool (RBT).

In

addition, precise acoustic measurements of the internal dimensions

of the casing and of its thickness provide a map-like presentation

of casing condition including internal and external damage or

deformation.

Rotating head ultrasonic (acoustic) imaging tools are the current

state of the art for cement and casing integrity mapping. The

rotating head gives greater circumferential resolution than the

segmented CET and CMT class of tools. The casing inspection

capability cannot be accomplished by other cement evaluation tools.

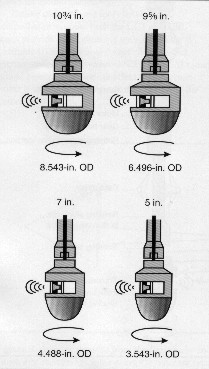

The

sonde includes a rotating transducer subassembly available in

different sizes to log all normal casing sizes. The direction

of rotation of the subassembly controls the orientation of the

transducer – counterclockwise for the standard measurement

mode (transducer facing the casing or the borehole wall), and

clockwise to turn the transducer 180 degrees within its subassembly

(transducer facing a reflection plate within the tool) to measure

downhole fluid properties. The fluid properties are used to correct

the basic measurements for environmental conditions. The

sonde includes a rotating transducer subassembly available in

different sizes to log all normal casing sizes. The direction

of rotation of the subassembly controls the orientation of the

transducer – counterclockwise for the standard measurement

mode (transducer facing the casing or the borehole wall), and

clockwise to turn the transducer 180 degrees within its subassembly

(transducer facing a reflection plate within the tool) to measure

downhole fluid properties. The fluid properties are used to correct

the basic measurements for environmental conditions.

Analysis

of the reflected ultrasonic waveforms provides information about

the acoustic impedance of the material immediately behind the

casing. A cement map presents a visual indicator of cement quality.

Impedance is measured in units of megaRayls.

INTERPRETATION

RULE 1: Low Amplitude = Good Cement

INTERPRETATION RULE 2: High Attenuation = Good Cement

INTERPRETATION RULE 3: High Bond Index = Good Cement

INTERPRETATION RULE 4: High Compressive Strength = Good

Cement

INTERPRETATION RULE 5: High Acoustic Impedance = Good Cement |

RAYL:

A unit of specific acoustic impedance in the centimeter-gram-second

system of units, = 10 pascal-seconds per meter. A specific

acoustic impedance has a magnitude of 1 rayl when a sound

pressure of 1 microbar produces a linear velocity of 1 centimeter

per second. The unit is named for John William Strutt, third

Lord Rayleigh (1842-1919). |

Like

the CET, the USI tool analyzes the decay of the thickness-mode

resonance signal contained in the reflected acoustic pulse, but

the analysis is performed in a different manner. The CET tool

has eight fixed transducers in a helical array, 45 degrees apart

azimuthally each seeing only a small segment of the casing. The

USI tool has a single rotating transducer that looks all around

the casing.

As

the acoustic impedance of the casing material and of the borehole

fluid are essentially constant, the signal inside the casing decays

at a rate that is dependent on the acoustic impedance of the material

outside the casing.

In

contrast to CET processing, which uses traditional energy windows,

USI processing derives acoustic impedance directly from the fundamental

resonance to measure the following:

1.

The acoustic impedance of the cement or whatever material is between

the casing and the formation.

2.

Casing thickness from the natural resonant frequency of the casing,

which is approximately inversely proportional to the wall thickness.

3.

Internal casing radius. The time between the firing and the major

peak of the echo is measured by locating the waveform peaks. Time

is converted to a measurement of the internal radius using the

fluid properties measurement to compute the velocity of sound

in mud, taking into account the transducer’s own dimensions.

4.

Casing inspection. The inside and outside diameters are determined

from the transit time and casing thickness measurements. The maximum

amplitude of the waveform provides a qualitative measure of the

internal surface rugosity of the casing.

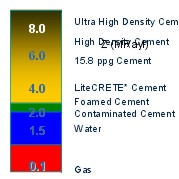

Several

presentations are available to address specific applications.

Negative conditions are indicated by the color red. For example,

red curves represent outputs for tool eccentering, minimum amplitude,

maximum internal radius, minimum thickness, gas index, and so

on. Increasing intensity of red in the images represents increasingly

negative conditions such as low amplitude, metal loss, and the

presence of gas in the cement map. The gas may be intentional,

as in foam cement, or unintentional from gas invasion as the cement

cures.

The

following log presentations are available from USI recordings:

1.

Fluid properties presentation, including fluid acoustic velocity,

acoustic impedance of fluid, and thickness of reference calibrator

plate.

2.

Cement Presentation, including cement properties curves, cement

map, and casing dimensions, plus synthetic bond index and minimum,

maximum and average values of acoustic impedance. Two cement images

are generated, one with and one without impedance thresholds.

3.

Corrosion Presentation with casing profile, casing reflectivity,

casing Internal radii, thickness image, Internal and external

radii, average and maximum thickness,

4.

Composite Presentation, with cement, corrosion measurements, and

processing flags. Two acoustic impedance images are presented:

one on a linear scale and one with thresholds corresponding to

the acoustic impedance of gas and mud.

5.

Impedance Images: 5.

Impedance Images:

Linear color scale

White < 0.5 MRayl = no cement.

Colors from yellow to brown represent steps of 0.5 MRayl.

Black < 8 MRayl - good cement.

With

thresholds

Red < 0.3 MRayl = gas intrusion

from formation or gas breakout

in foam cement.

Blue < 2.6 MRayl = fluid – water

or mud in cement.

Yellow < 3 MRayl = foam cement

or very contaminated neat

cement.

Colors from yellow to brown represent steps of 0.5 MRayl and indicate

solids, eg. Cement or cement extenders.

Black < 8 MRayl = high quality neat cement.

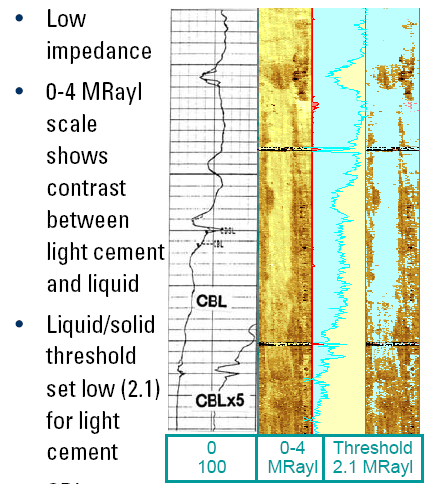

These

thresholds can be varied for conditions such as light cement (where

lower acoustic impedance indicates lower fluid cutoff) and heavy

mud (with a higher fluid threshold cutoff). Check the colour scale

on each log.

6.

Amplitude images:

The amplitude image, derived from the amplitude of the main echo

of each waveform, represents the reflectivity of the internal

surface of the casing. The image is normalized with respect to

the maximum value at a given depth, and all points are presented

in terms of attenuation from the maximum amplitude at that depth.

Normalized minimum amplitude curves are plotted.

Linear

color scale

Black = low signal (-6 dB) = good bond

Colors from dark red to white represent steps of 0.5 dB

White = high signal (0 dB) = no bond

7.

Diagnostic images:

Processing flags – diagnostics for the field engineer.

8.

Internal radius images:

The internal radius image shows the variations around IRAV, the

average

radius at each depth. Two color scales are used – blue to

white for

internal radii less than IRAV and white to red for internal radii

greater

than IRAV. Each color step represents 0.008 in.

9.

Thickness images:

The thickness image shows the variations around THAV, the average

value of the thickness at each depth. Two color scales are used

– red

to white for thicknesses less than THAV and white to blue for

thicknesses

greater than THAV.

Alternate

images that plot internal radius and thickness versus API specifications

of the casing are available.

The

acoustic impedance of the mud must be accurately known to within

10 percent in order to obtain a 0.5-MRayl accuracy in cement.

The acoustic impedance of the mud is provided by the downhole

fluid properties measurement, which is normally acquired while

tripping into the well.

A

microannulus affects the apparent cement acoustic impedance. Laboratory

experiments show that a 100-micron (0.004 inch) microannulus results

in a 50 percent loss in apparent impedance. Even the smallest

liquid-filled microannulus causes the loss of shear coupling into

the cement and a drop of approximately 20 percent in impedance.

Whenever the presence of a microannulus is suspected, the USI

tool should be run under pressure to obtain an improved acoustic

impedance measurement.

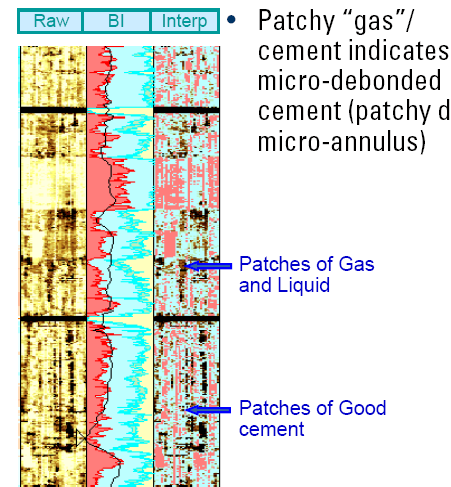

A

dry microannulus is called micro-debonding and gives a patchy

looking cement image.

The

USI tool can resolve the impedance of the material filling a channel

down to 1.2 inches, which is therefore the minimum quantifiable

channel size. The angular resolution improves for larger diameter

casing, from 30 degrees in 4.5-in. casing to 10 degrees in 13

3/8-in. casing. However, interpretation is required since channels

are not always surrounded by high-impedance cement nor are they

always filled with low impedance material.

EXAMPLES

EXAMPLES

The

following examples are courtesy of Schlumberger.

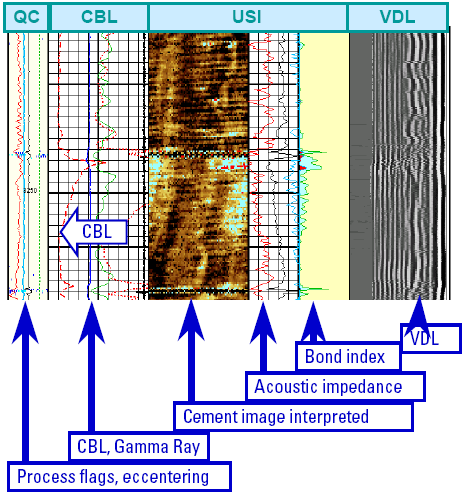

Typical USI composite presentation with cement

images, synthetic bond index, and casing image.

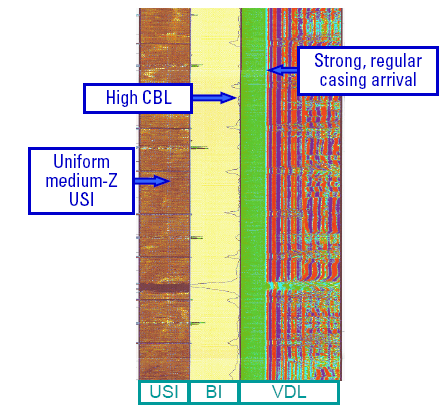

Combination of USI and CBL-VDL gives more complete

picture – high resolution from USI and formation arrivals

on VDL.

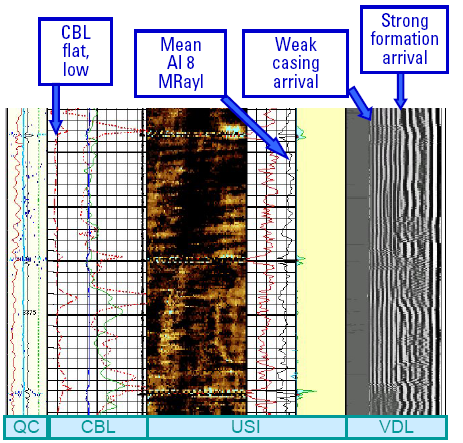

Good cement – low amplitude on CBL, high Acoustic

Impedance on USI, no serious channels on image.

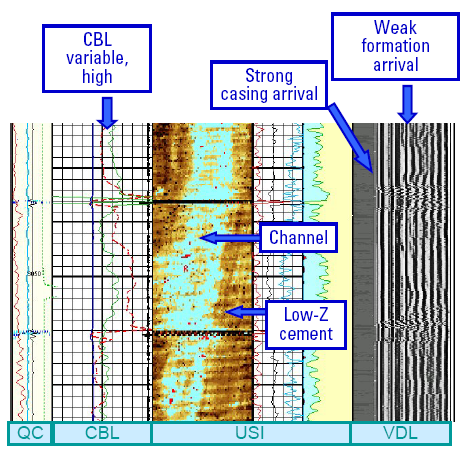

Poor cement – high amplitude on CBL, low

Acoustic Impedance (blue colour) on image indicates large void

space filled with liquid (mud).

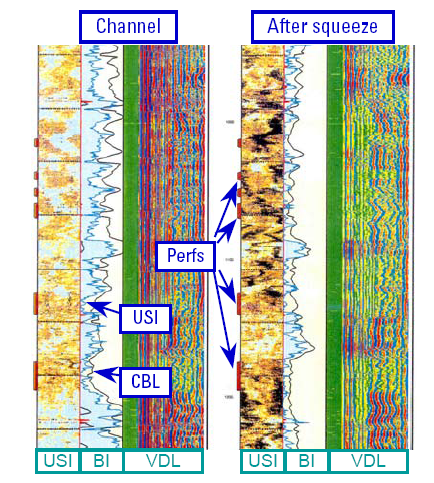

USI-VDL and USI before and after squeeze.

CBL and USI in foam cement.

Microannulus – high amplitude on CBL and

VDL, medium to high acoustic impedance on USI.

Micro-debonding – similar to microannulus

but patchy instead of continuous.

Samples of cement jobs with problems, and possible

cures.

|