|

fractured reservoir basics

fractured reservoir basics

Natural fractures in reservoir rocks contribute

significantly to productivity. Therefore, it is important to

glean every scrap of information from open hole logs to

locate the presence and intensity of fracturing. Even

though some modern logs, such as the formation micro-scanner and

televiewer, are the tools of choice for fracture indicators, many

wells lack this data. Thus all known fracture location techniques

are described.

Naturally

fractured reservoirs contain secondary or induced porosity in

addition to their original primary porosity. Induced porosity

is formed by tension or shear stresses causing fractures in a

competent or brittle formation. Fracture porosity is usually very

small. Values between 0.0001 and 0.001 of rock volume are typical

(0.01% to 0.1%) Fracture-related porosity, such as solution porosity

in granite or carbonate reservoirs, may attain much larger values,

but the porosity in the actual fracture is still very small. Naturally

fractured reservoirs contain secondary or induced porosity in

addition to their original primary porosity. Induced porosity

is formed by tension or shear stresses causing fractures in a

competent or brittle formation. Fracture porosity is usually very

small. Values between 0.0001 and 0.001 of rock volume are typical

(0.01% to 0.1%) Fracture-related porosity, such as solution porosity

in granite or carbonate reservoirs, may attain much larger values,

but the porosity in the actual fracture is still very small.

There

are, of course, exceptions to all rules of thumb. In rare cases,

such as the cooling of intrusives or surface lava flows, in which

natural fracture porosity may exceed 10%. When buried and later

filled with hydrocarbons, they form very interesting reservoirs.

Fracture

analysis literature in the 1970’s suggested that fractures

might contribute as much as a few to several percent porosity.

More modern work using fracture aperture calculated from resistivity

micro-scanner logs indicates much lower numbers. To appreciate

this, consider fractures with 1 millimeter aperture spaced 1 meter

apart. This gives a porosity of 0.001 fractional (0.1%). This

is a very large open fracture. Most are only microns in width,

so even 10 fractures of 10 microns each only give 0.0001 fractional

porosity (0.01%).

The

term “secondary porosity” also includes rock-volume

shrinkage due to dolomitization, porosity increase due to solution

or recrystalization, and other geological processes. “Secondary

porosity” should not be confused with “fracture porosity”.

Porosity formed in this way can be determined from modern log

suites without difficulty, except for porosity formed by fractures, which is

too small to detect with conventional logs.

Fracture

porosity is found accurately only by processing the formation

micro-scanner curves for fracture aperture and fracture frequency

(fracture intensity). All other methods, including the well known

“dual-porosity” model, are extremely inaccurate. These

models either over-estimate fracture porosity by several orders

of magnitude, or cannot be applied because the log data does not

fit the model. All published models are described in this

Handbook

and the student or practitioner can decide whether or not to use

them. Fracture

porosity is found accurately only by processing the formation

micro-scanner curves for fracture aperture and fracture frequency

(fracture intensity). All other methods, including the well known

“dual-porosity” model, are extremely inaccurate. These

models either over-estimate fracture porosity by several orders

of magnitude, or cannot be applied because the log data does not

fit the model. All published models are described in this

Handbook

and the student or practitioner can decide whether or not to use

them.

The

effect of fracture porosity on reservoir performance, however,

is very large due to its enormous contribution to permeability.

As a result, naturally fractured reservoirs behave differently

than un-fractured reservoirs with similar porosity, due to the

relative high flow capacity of the secondary porosity system.

This provides high initial production rates, which can lead to

extremely optimistic production forecasts and sometimes, economic

failures when the small reservoir volume is not properly taken

into account.

Reservoir

simulation software that accounts for the fracture system is often

termed a “dual porosity” model. While this is strictly

true, it would be better to think of them as “dual permeability”

models, since the fracture permeability fed by the matrix or reservoir

permeability is far more important than the relative storage capacity

of the fractures and matrix porosity. A reservoir with only fracture

porosity is quickly depleted; a decent reservoir in the matrix

rock feeding into fractures will last much longer.

In

order to understand the behavior of naturally fractured reservoirs,

estimates must be made of hydrocarbons-in-place within both the

primary (matrix rock) and secondary (fracture-only) porosity systems.

To do this, we must first be able to detect the existence of fractures.

Therefore, this chapter covers fracture detection from the usually

available conventional logs, as well as the method used to partition

porosity into primary and fracture components. The effect of this

partitioning on the Archie water saturation equation is also described.

Modern methods for quantifying fracture porosity directly from

micro-scanner logs are also discussed.

Definition of Fractures Definition of Fractures

A fracture is a surface along which a loss of cohesion in the

rock texture has taken place. A fracture is sometimes called a

joint and, at the surface, are expressed as cracks or fissures

in the rocks.

The orientation of the fracture can be anywhere from horizontal

to vertical. The rough surface separates the two faces, giving

rise to fracture porosity. The surfaces touch at points called

asperities. Altered rock surrounds each surface and infilling

minerals may cover part or all of each surface. Minerals may fill

the entire fracture, converting an open fracture to a healed or

sealed fracture.

Fracture Porosity Definitions

Fractures are caused by stress in the formation, which in turn

usually derives from tectonic forces such as folds and faults.

These are termed natural fractures, as opposed to induced

fractures. Induced fractures are created by drilling stress or

by purposely fracturing a reservoir by hydraulic pressure from

surface equipment. Both kinds of fractures are economically important.

Induced fractures may connect the wellbore to natural fractures

that would otherwise not contribute to flow capacity.

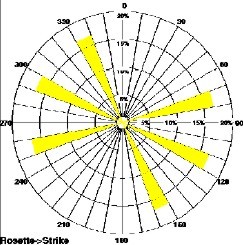

Natural

fractures are more common in carbonate rocks than in sandstones.

Some of the best fractured reservoirs are in granite - often referred

to as unconventional reservoirs. Fractures occur in preferential

directions, determined by the direction of regional stress. This

is usually parallel to the direction of nearby faults or folds,

but in the case of overthrust faults, they may be perpendicular

to the fault or there may be two orthogonal directions. Induced

fractures usually have a preferential direction, often perpendicular

to the natural fractures. A schematic diagram of these relationships

is shown above, bottom right.

A

fracture is often a high permeability path in a low permeability

rock, or it may be filled with a cementing material, such as calcite,

leaving the fracture with no permeability. Thus it is important

to distinguish between open and healed fractures. The total volume

of fractures is often small compared to the total pore volume

of the reservoir.

Most

natural fractures are more or less vertical. Horizontal fracture

may exist for a short distance, propped open by bridging of the

irregular surfaces. Most horizontal fractures, however, are sealed

by overburden pressure. Both horizontal and semi-vertical fractures

can be detected by various logging tools.

The

vertical extent of fractures is often controlled by thin layers

of plastic material, such as shale beds or laminations, or by

weak layers of rock, such as stylolites in carbonate sequences.

The thickness of these beds may be too small to be seen on logs,

so fractures may seem to start and stop for no apparent reason.

To

be an aid in production, fractures must be connected to a

reasonable hydrocarbon bearing reservoir with sufficient volume

to warrant exploitation. If there is no reservoir volume, a lot

of fractures won’t help much unless there is sufficient fracture

related solution porosity to hold an economic reserve. This can

be determined by normal log analysis techniques. In reasonable

non-fractured reservoirs, it is usually possible to estimate

permeability, and hence productivity,

but this is not always possible in fractured reservoirs. Although

both the presence of fractures and the presence of a reservoir

can be determined from logs, a production test will be needed

to determine whether economic production is possible. The test

must be analyzed carefully to avoid over optimistic predictions

based on the flush production rates associated with the fracture

system. Local correlations between fracture intensity observed

on logs and production rate are also used to predict well quality.

Sometimes

the primary reservoir and the fracture system may be so poorly

connected that they are saturated with different fluids. Production

from fractures full of hydrocarbons in a water bearing formation

may initially be very good but very short lived. A more desirable

scenario is a primary reservoir with appreciable hydrocarbon saturation

and a fracture system that is full of water close to the borehole,

showing invasion and hence good permeability, but full of hydrocarbon

in the uninvaded formation. Sometimes

the primary reservoir and the fracture system may be so poorly

connected that they are saturated with different fluids. Production

from fractures full of hydrocarbons in a water bearing formation

may initially be very good but very short lived. A more desirable

scenario is a primary reservoir with appreciable hydrocarbon saturation

and a fracture system that is full of water close to the borehole,

showing invasion and hence good permeability, but full of hydrocarbon

in the uninvaded formation.

Usung Logs to Locate Fractures

Usung Logs to Locate Fractures

Fracture

location from well logs can be divided into two categories,

namely wells with image logs and wells without image logs. Using

conventional open hole logs is mandatory in older wells before

the era of image logs, and still widely needed today because

image logs are not always run where they are need. As a result

we are forced to ise what we have. Using conventional logs is

covered in the next Section.

Of

course, it would be preferable to run the right logs in the first

place. These would include the resistivity or acoustic image log and

the dipole shera sonic log. A preview of these modern logs is given

below, with more detail in Section 3. Case histories aree in Section

4.

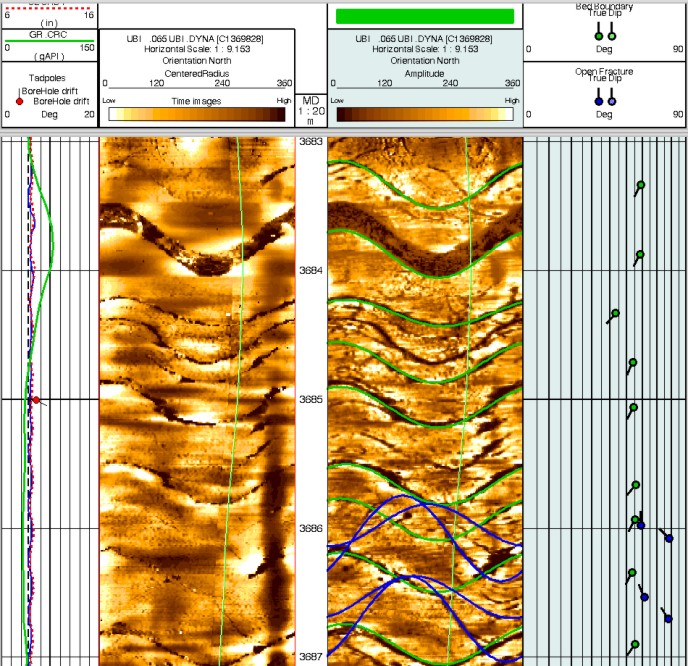

Acoustic Image log with travel time (detailed borehole

radius) at left and amplitude (acoustic impedance) on the right.

Fractures show up as black sinusoid shapes on both images. The

strike direction (azimuth) of the fracture can be picked at the

trough on the sinusoid and converted to a compass orientation using

the scale at the top of the log. Dip angle of the fracture can be

found by comparing the peak to peak amplitude of the sine wave (in

borehole depth units) to the borehole diameter (measued in the same

units).

DIP = arctan (Y/D) where Y = peak to peak distance and D = borehole

diameter.

With some skill and daring, the image

logs can be interpreted for open, healed, and induced

fractures, and the stress regime for each can be worked out seoarately.

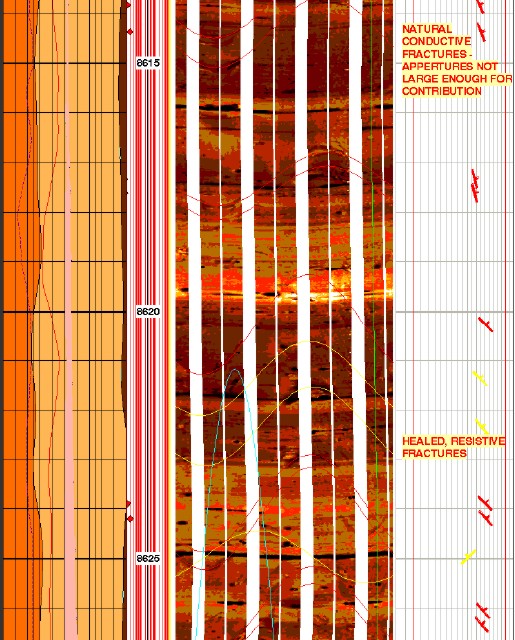

Resistivity

image log in fractured reservoir: gamma ray (left track, shaded

red), image track (middle) with open fractures (red sine waves and

healed fractures (yellow sine waves), dip track (right) shows red

amd yellow dip angle and azimuth. There are no induced fractures in

this short interval. Bedding planes are near horizontal. Imagine

trying to locate these steep dips without the aid of a computer.

.

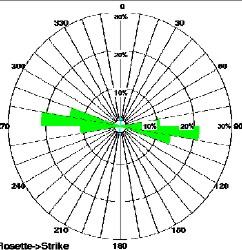

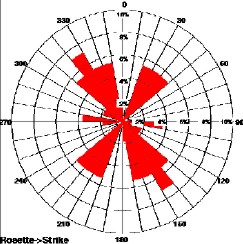

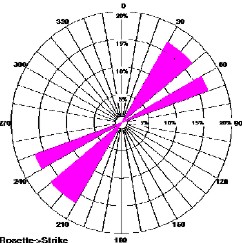

Induced fractures (top left) show current stress direction. Open

fractures (top right) show stress direction when fractures were

created, healed fractures (lower left) show different direction at

an earlier phase in geological time, and micro faults (lower right)

shows another stress regime was present when the faults occurred.

The

newest dipole shear sonic log is also an azimuthal tool with dipole

sources set at 90 degrees to each other. The example below shows the shear images for the X and Y directions. This

log can be run in open or cased hole.

Dipole shear image log shows directional stress

- the Fast Direction is centered on

90 degrees (east - west) which

is also the maximum stress direction.

|