|

Fracture Identification From IMAGE LoGS

Fracture Identification From IMAGE LoGS

Resistivity imager

logs, also called microscanner or FMS or FMI logs, carry an array of electrodes on pads used to produce an electrical

image of the formations seen on the borehole wall. Acoustic

image logs, also called televiewer or CBIL logs, use a

rotating transducer to measure acoustic impedance images

over the entire borehole wall, as well as an acoustic

caliper. Microscanners have better vertical resolution and

dynamic range than televiewers, but televiewers see the

entire wellbore while microscanners usually see less than

100%.

On earlier

microscanner tools, the image arrays were on only two of the four pads, so

several logging passes of the tool had to be merged together for

better borehole coverage. Using this technique, from forty to

eighty percent wellbore coverage could be achieved. Newer tools

now have four or eight active imaging pads, reducing the need

for repeat passes to obtain 100% coverage of the borehole wall.

In

addition to the array electrodes, the tool also has ten standard

dipmeter electrodes (8 measure electrodes plus 2 speed buttons)

as well as a directional cartridge containing accelerometers and

magnetometers for orientation input to the standard dip computations.

The

electrical images are made by applying a gray scale to the resistivity

wiggle-traces produced from the electrodes on the tool. In this

way, low resistivity zones appear dark and high resistivity, low

porosity intervals appear white. Since the array on each pad is

two and a half inches wide, irregular features, such as vugs and

fractures, show up as dark spots and lines on the images. Colour

tones may be used instead of grey.

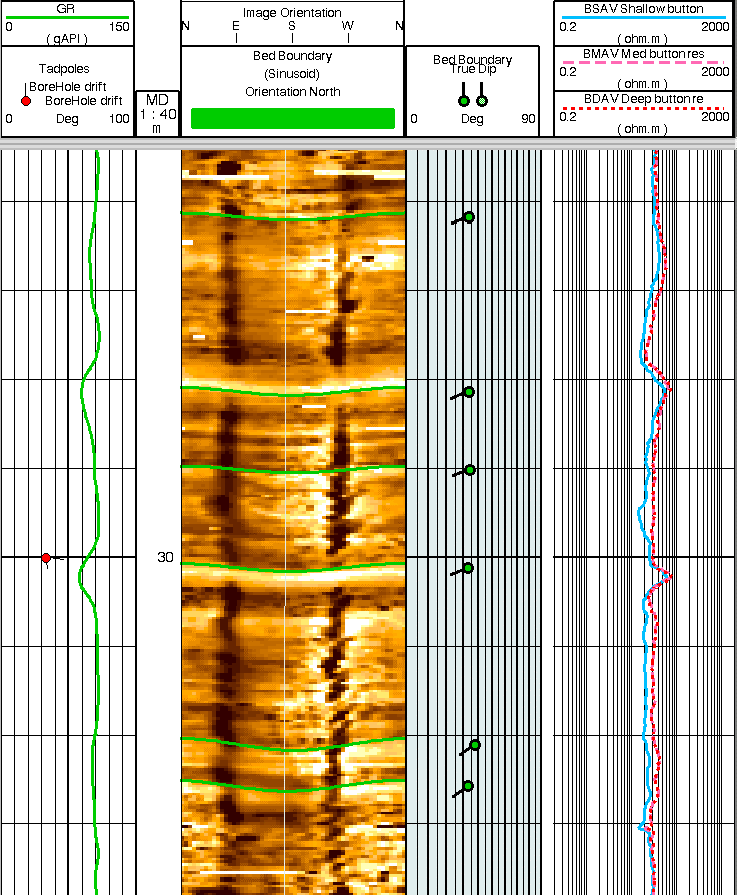

Formation micro-scanner shows fractures and bedding

planes

The

image depth scale is usually 1:20 or 1:40, and the X axis is scaled

from -180 to +180 degrees around the borehole, putting North in

the middle of the track. Examples are provide above. A dramatic near vertical fracture can be seen. Two vertical scales are used:

one for reconnaissance and one for detail evaluation. Fracture

orientation is roughly NNW - SSE dipping at more than 80 degrees.

Other images on these two figures illustrate induced fractures,

borehole breakout, inter-bedding laminations, slump brecchia,

vugs with fractures, and stylolites.

Formation micro-scanner shows porosity features

sometimes

Fractures

should produce a higher contrast anomaly than other porosity features

because the fractures are flushed with conductive borehole fluid

and there is exaggeration of the anomaly due to breakout of the

wellbore on the fracture. The fractures are sometimes masked,

however, by extremely conductive vugs, so both the gray scale

images and the electrical wiggle-trace data are analyzed to identify

fractures. Resolution of the micro-scanner is about 10 mm, but

contrast between fractures and rock is so good that thinner events,

as thin as a few microns, can often be seen.

Micro-scanner

images give a very good visual correlation to core and allow the

interpretation of small and large scale sedimentary features in

the formations. The identification of fractures, along with fracture

orientation, and the ability to differentiate them from high angle

bedding features is possible.

FMI log in fractured granite reservoir showing

computed dip angle and direction

Further

processing of the images to generate fracture frequency and fracture

aperture is now routinely applied to the newest formation micro-imaging

(FMI) logs. Older logs can be reprocessed for frequency and aperture

only if data tapes still exist. The product of frequency and aperture

is fracture porosity.

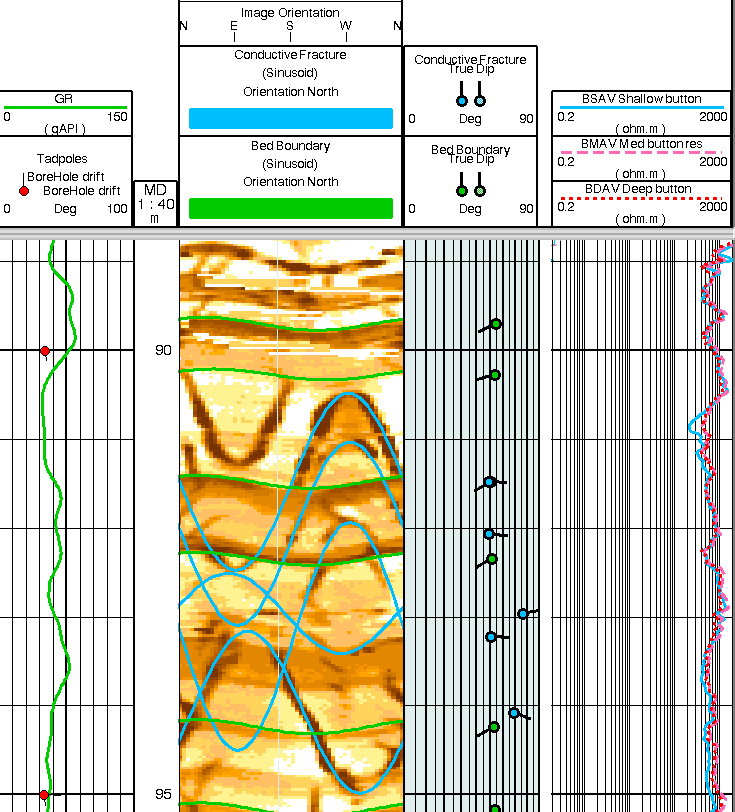

Typical Resistivity-At-Bit (RAB) image log shows gamma ray at

left, resistivity image, dip tadpoles, and 3 resistivity curves

on the right. This image illustrate open fractures (with blue

traces) cross-cutting bedding (in green).

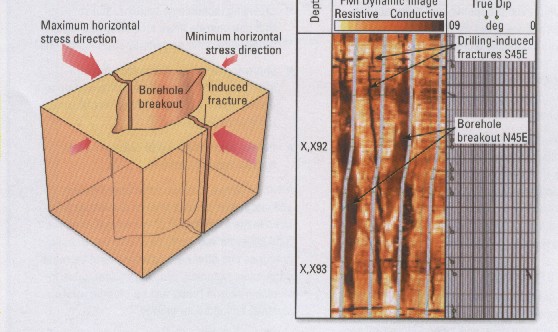

This is an RAB image of an induced fracture )borehole breakout),

not a natural fracture. Induced fractures run parallel to the

borehole axis. Natural fractures almost always cross the borehole.

Fracture

Identification From Acoustic Image Logs

Fracture

Identification From Acoustic Image Logs

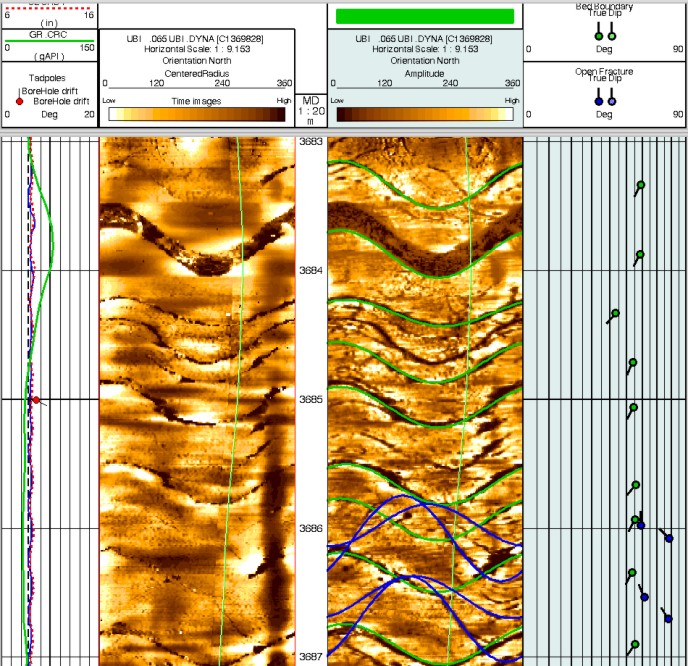

The acoustic

image log (borehole televiewer) is similar in appearance to a

resistivity image log (formation micro-scanner),

but uses an ultrasonic derived, directionally oriented,

360 degree view of the borehole wall.

Such an image, created by

a conventional televiewer, has sufficient resolution to see major

fracture systems in good hole conditions. The hole must be round,

smooth, and filled with light weight mud to get really good images.

The tool must be well centered. These requirements are not met

in most fractured zones, but logs are still run for fracture identification

and they are useful in many cases. Trade names for these tools

are not as well known as others: CBIL (pronounced Cybill) stands

for Continuous Borehole Image Log and UBI for Ultrasonic Borehole

Imager. Versions of these tools are also used for cement evaluation

in cased holes.

The

televiewer log of the wellbore is a representation of the amount

of acoustic energy received at the transducers, which is dependent

upon rock impedance, wall roughness, wellbore fluid attenuation,

and hole geometry. For example, a smooth surface reflects better

than a rough surface, a hard one better than a soft one. A surface

perpendicular to the transducers reflects better than one that

is skewed. Therefore, any irregularities such as fractures, vugs

and irregular porosity will reduce the amplitude of the reflected

signal.

Acoustic Image log with travel time (detailed borehole radius) at

left and amplitude (acoustic impedance) on the right. Fractures show

up as black sinusoid shapes on both images.

Comparison of resistivity image

log (left) and ultrasonic image log in the same borehole. The higher

spatial resolution and the higher dynamic range of the resistivity

image is clear. Black colour represents low acoustic impedance on

CBIL/ UBI, or low resistivity on FMI, in this case representing

fractures (near vertical) or shale beds (near horizontal).

Older acoustic televiewer log (left) and interpretation

image (right)

The

resolution of the tool allows us to determine events of about

10 mm in width. Fractures are often accentuated in the wellbore

by the drilling process, which breaks out the fracture on both

sides of the opening. If it were not for this breakout, most fractures

would not be seen by the televiewer as their width is commonly

less than 1 mm. An example of an actual image from an older televiewer

log, and an interpretive sketch with artificially enhanced resolution. The formation microscanner is much more

sensitive to fractures than the televiewer. The electrical conductivity

of the fluid in the fracture is 1000 or more times higher than

the surrounding rock, compared to about 4 times for acoustic televiewer

signals.

In

addition to the amplitude image, the travel time image is also

recorded on modern logs. This is the travel time from tool to

wellbore wall and back to the detector through the mud. This image

is effectively an acoustic caliper log, and is used to locate

breakouts.

Considerable

research is being conducted to enhance the televiewer images,

using both arrival time and amplitude of the sound waves, plus

computer methods for image enhancement, especially edge enhancement

to resolve fractures and bed boundaries. Modern televiewer logs

can be used effectively in more rugged boreholes than older versions

because of the new processing techniques. Be aware of the age

of the log before you start your analysis.

Since

the televiewer image is oriented to magnetic north, we can determine

the dip direction of a fracture or bedding plane from the azimuth

of the troughs of the sinusoid. The dip angle can be calculated

from the same equation as given for the microscanner.

CAUTION:

The direction scale on the top of the image varies between service

companies. One uses a scale with North in the center of the image

(same as for FMS and FMI), another puts South in the center.

Here

is a televiewer and core photo of the same fracture.

The sinusoidal shape of the fracture trace is very obvious. In

this image, South is in the center of the track and the fracture

is oriented N 70 E, with a thinner, steeper fracture at N 45 W. Here

is a televiewer and core photo of the same fracture.

The sinusoidal shape of the fracture trace is very obvious. In

this image, South is in the center of the track and the fracture

is oriented N 70 E, with a thinner, steeper fracture at N 45 W.

Core photo (left) and televiewer image (right) of fractured

interval Core photo (left) and televiewer image (right) of fractured

interval

Fracture

identification is easiest when several detection methods are combined.

This is illustrated in Figures 28.31 and 28.32, where sonic variable

intensity and televiewer images are used. If density of the rock

is also measured, numerous elastic properties of the rock can

be derived, which are useful in hydraulic fracture design and

sanding studies.

Wavetrain and televiewer image with minor fracturing

The

televiewer has a few advantages over the formation microscanner.

These are the ability to see 360 degree image of the borehole,

no need for pad contact, ease of use in oil base muds, high resolution

acoustic caliper, and better steep bed definition due to shallow

investigation. The microscanner has better resolution in rough

hole and has higher dynamic range due to using resistivity contrast

instead of acoustic impedance contrast.

direction at right angles to this

axis. On real, logs check heading carefully, as travel time and

amplitude images can be interchanged in position, and North may be

on the right or the middle of the track.

A

resistivity image log has about 10 times the spatial resolution of an

acoustic image log

and 500 times the amplitude resolution, due to the difference

in contrast between the resistivity and acoustic impedance ranges

measured by the respective tools.

Determining Fracture

DIP and Orientation

Determining Fracture

DIP and Orientation

Fractures

or bedding planes can be identified by connecting the linear features

to form a sinusoid on the image. The sinusoid can be analyzed

to find the angle of dip:

1:

Angle of Dip = Arctan (Y / D)

Where:

Y = peak to peak distance of the sinusoid (millimeters)

D = hole diameter (millimeters)

Since

Y is measured on a plot or CRT, it must be transformed into actual

wellbore distance by multiplying the measured distance by the

plot scale. Note also that near vertical fractures will appear

near vertical on the plot and do not form sinusoids.

Fracture orientation is determined by the azimuth of the

sinusoid troughs, read from the direction scale at the top of

the image. If image logs are not available, there are other

techniques that might be helpful in estimating the orientation

od fractures, described below.

When formation pressure is isotropic (equal

in all directions), the tectonic stress is zero and Pfrx equals

Pfry. In this situation, the borehole is round and spalling of

the formation is either non-existent or equal in all directions.

In stressed regions, such as in the Rocky Mountains, the borehole

will erode to an oval shape. The minimum diameter shows the direction

of maximum stress and the maximum diameter shows the direction

of minimum stress..

Borehole shape indicates stress direction –

maximum stress in direction of minimum hole

diameter. Formation microscanner and dipmeters have oriented caliper data.

Many

modern logs have an X and Y axis caliper, but not all of them

are oriented to true north. When directional data is recorded,

as with dipmeters and many modern resistivity tools, the X and

Y orientations are known, Statistical plots are helpful in choosing

the dominant direction).

Borehole diameter indicates stress direction -

this example is from India where the minimum

stress direction

is NE - SW.

A

hydraulic fracture will usually penetrate the formation in a plane

normal to minimum stress, or parallel to the plane of maximum

stress. Any stress anisotropy (tectonic stress) will cause the

fracture to be other than vertical. A

hydraulic fracture will usually penetrate the formation in a plane

normal to minimum stress, or parallel to the plane of maximum

stress. Any stress anisotropy (tectonic stress) will cause the

fracture to be other than vertical.

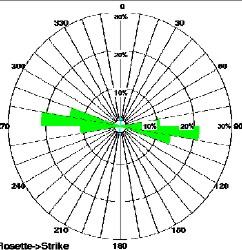

Natural

fractures take the same directions as hydraulic fractures, indicated

again by the borehole shape. In addition, the high angle dips

seen on an open hole dipmeter or image log, will also indicate this preferential

direction. Since most hydraulic fracture jobs are run in casing,

it is not possible to run a dipmeter or caliper survey to find

the orientation of a hydraulic fracture. The preferential direction

can be predicted from previous open hole data. Dipmeter and caliper

data can be displayed on rose diagrams to illustrate preferential

directions.

If

an azimuthal gamma ray log existed, the fracture orientation could

be located by a tracer survey. I am not aware that such a tool

exists, but it would not be difficult to design one..

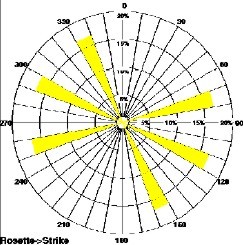

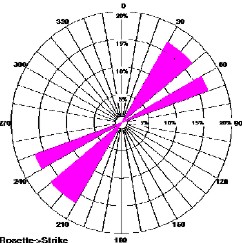

Azimuth frequency (rose diagram) plots show direction of

dips seen on dipmeter and image logs. When steep dips caused by

fractures are isolated from lower angle bedding dips, the

direction of maximum stress xan be determined. In this case, the

direction is N30E. Azimuth frequency (rose diagram) plots show direction of

dips seen on dipmeter and image logs. When steep dips caused by

fractures are isolated from lower angle bedding dips, the

direction of maximum stress xan be determined. In this case, the

direction is N30E.

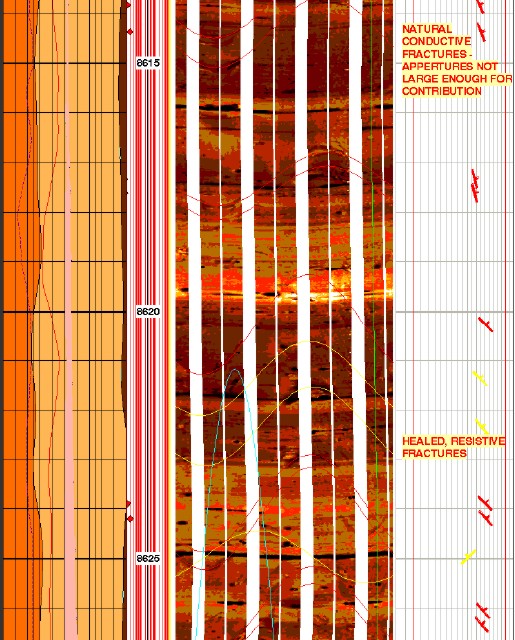

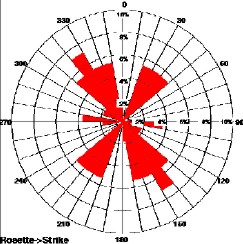

Stress

direction is not constant over geological time scales. Differences

in the direction of induced fractures (present day stress

direction), open fractures (some time ago), healed fractures (older

than open fractures), and small faults (could be any age) will help

to show the stress history of a region. An example log and rose

diagrams are shown below.

Image log in fractured reservoir: gamma ray (left track, shaded

red), image track (middle) with open fractures (red sine waves and

healed fractures (yellow sine waves), dip track (right) shows red

amd yellow dip angle and azimuth. There are no induced fractures in

this short interval. Bedding planes are near horizontal. Imagine

trying to locate these steep dips without the aid of a computer.

.

Induced fractures (top left) show current stress direction. Open

fractures (top right) show stress direction when fractures were

created, healed fractures (lower left) show different direction at

an earlier phase in geological time, and micro faults (lower right)

shows another stress regime was present when the faults occurred.

The

newest dipole shear sonic log is also an azimuthal tool with dipole

sources set at 90 degrees to each other. The example below shows the shear images for the X and Y directions. This

log can be run in open or cased hole.

Dipole shear image log shows directional stress

- the Fast Direction is centered on

90 degrees (east - west) which

is also the maximum stress direction.

|