|

fracture LOCATION FROM SONIC LOGS

fracture LOCATION FROM SONIC LOGS

There is much literature concerning the effect of fractures on

acoustic wave propagation in porous and fractured rock. Unfortunately,

much of it is theoretical and not always supported by field examples;

often it is contradictory. Nevertheless, the sonic log is the

best fracture finder in older wells because other, more modern,

methods were unavailable at the time.

Today,

dipmeter and formation micro-scanner images provide more information,

but at higher cost, so sonic logs are still used extensively for

fracture identification. The modern full wave or array sonic and

dipole shear sonic tools provide much new information, including

shear wave travel time and amplitude plus full wave-train digitization

This allows the wave train to be further processed.

In

theory, the normal compressional interval transit time is little

affected by fractures so long as there is a free matrix path between

transmitter and receivers, as would be expected for vertical fractures.

In practice, large vertical and most sub-horizontal fractures,

create cycle skipping on the compressional transit time curve

on all sonic logs that rely on detection of the first energy arrival.

This is due to reduction in amplitude of the sound pulse by reflection

at the fracture face, and by destructive interference caused by

other propagation modes generated at the fracture. In addition,

refraction caused by near vertical fractures diverts energy from

the receivers, again reducing amplitude.

Cycle

skipping makes the sonic travel time too long. Thus simple theory

is overwhelmed by the complexity of sound transmission in a heterogeneous

medium. Cycle

skipping makes the sonic travel time too long. Thus simple theory

is overwhelmed by the complexity of sound transmission in a heterogeneous

medium.

Sonic log cycle skips may indicate fractures

Sonic log cycle skips may indicate fractures

On

the array and dipole shear sonic logs, travel time is usually found by

waveform correlation and not by first arrival detection

(although both methods are available). Therefore,

it is less likely to skip a cycle due to low amplitude. Amplitude

curves are presented as a matter of routine, so fractures can

be identified by low compressional and shear amplitudes. Sonic

curves on the array or dipole sonic can disappear or be shown

as straight lines where amplitude is too low to obtain a waveform

correlation.

Cycle

skipping is an excellent fracture indication in hard formations.

Shallow resistivity crossover might help confirm fractures

in a typical well with only an induction and sonic log.

Gas

in the formation or in the mud, poor borehole conditions, and

poor tool condition or recording parameters, especially on older

logs, may also cause skipping. Tool centralization is also important;

compressional amplitude can be reduced to less than 20% of normal

with the tool only 1 inch off center. This can cause skipping. Note that most modern sonic logs are

designed to avoid cycle-skipping so this identification technique

may not be useful in many newer wells.

Compressional and shear sonic amplitude versus

fracture orientation and tool centering

The

cause of the skipping can be checked; if the skips occur only

in a competent zone and not in the surrounding shales, gas in

the formation or fractures are the only possibilities. Cycle skipping

is more common on long spaced than on short spaced sonic logs

in hard formations, because of lower sound amplitude on longer

tools. The reverse is often true in softer sands and shales, due

to rock alteration near the wellbore.

In

contrast, shear energy is, theoretically, strongly reduced by

both horizontal and vertical fractures, but not much by fractures

between 35 and 75 degrees. In practice,

fluids and fluid filled fractures do not conduct shear waves,

and shear arrivals are strongly attenuated in fractured zones. On full wave or array sonic presentations,

the absence of shear arrivals or straight line segments on shear

travel time logs are sure signs of fractures. The Stoneley wave

amplitude is also strongly reduced by fractures.

To

differentiate between fractures and other causes of skipping,

a number of different logging tool designs and presentations of

sonic data have been developed. Special presentations include

the sonic amplitude, sonic wavetrain, and variable intensity (variable

density) displays, discussed below.

The

sidewall acoustic instrument was introduced to improve the bed

resolution and measurement of acoustic properties, but it was

not widely available or used. It is an acoustic pad device containing

one transmitter and two receivers designed to reduce attenuation

in the borehole and through the rock. The distance from the transmitter

to the first receiver is 9 inches, and the spacing between the

receivers is 6 inches. These dimensions allow for better bed definition

for porosity measurements and improved wave forms for fracture

studies.

Fractures

are more readily identifiable from this short spaced measurement

than from devices which measure and average a longer distance.

However, the measurement is affected by borehole rugosity and

only surveys a small portion of the borehole circumference. It

is best suited for thin bedded formations.

Sonic Waveform Logs

Sonic Waveform Logs

The

elastic constants of rocks determine the velocity of sound waves. Compressional

waves travel faster than shear waves and theoretically can be

seen separately on a display of sonic waveforms. Waveforms are

a record of sonic energy level versus arrival time. In practice

the two waves, and others, interfere with each other to some extent.

The

amplitude of both waves are affected by the rock type, porosity,

borehole rugosity, tool centralization, formation fluid, and fracture

size and orientation. The fractures may be only those induced

near the borehole wall by drilling or may be in-situ. Closed fractures

reduce the amplitude less than open fractures. Refracted waves

traveling other than direct ray paths can also reduce amplitude

and give false impressions of fracturing.

The

usual way to record these amplitude values is to present the amplitude

of the first energy arrival, which is from the compressional wave,

in the form of a log curve, or to present the entire wavetrain,

or both. On the newer array and dipole shear sonic, the shear

amplitude is also displayed. On older logs, some attempts were

made to measure shear travel time and amplitude by adjusting gate

times and trigger levels on the instrument panel. These logs were

not too reliable, so take care if trying to use them. The

usual way to record these amplitude values is to present the amplitude

of the first energy arrival, which is from the compressional wave,

in the form of a log curve, or to present the entire wavetrain,

or both. On the newer array and dipole shear sonic, the shear

amplitude is also displayed. On older logs, some attempts were

made to measure shear travel time and amplitude by adjusting gate

times and trigger levels on the instrument panel. These logs were

not too reliable, so take care if trying to use them.

Sonic amplitude log may indicate fractures Sonic amplitude log may indicate fractures

Numerous

versions of these logs have been developed over the years, with

little standardization. Names such as Micro-seismogram, Fracture

Finder, 3-D Velocity, Acoustic Parameter, Shear Sonic, Variable

Density, and Frac Log were used by various suppliers. We will

use the generic term sonic amplitude log to cover all of these.

The

sonic amplitude log is a curve representing the first arrival

energy, measured in milli-volts. Energy varies with many factors,

so absolute values mean little, but low amplitude often means

fractures. All the things that cause cycle skipping, described

above, cause low amplitude, so fractures are only one possibility.

This log is usually combined

with a gamma ray, caliper, and a wavetrain presentation, as shown.

The

sonic wavetrain log is a display of the recorded energy presented

as wiggly trace signatures, usually one for every 6 inches to

2 feet of borehole. The variable intensity display, sometimes

called a variable density log, displays the same waveform information,

but the amplitude of the positive peaks are shaded gray or black

and negative peaks are white. When plotted continuously, dark

and light bands representing peaks and valleys are displayed versus

depth. Conventions have varied, and arrival time has been plotted

increasing right to left or left to right, with the latter used

today.

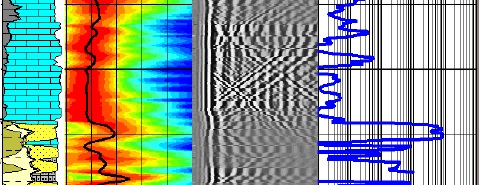

Sonic waveform presentation

Two

waveform logs, with associated gamma ray logs are shown above. Compressional amplitudes are lower than shear in most cases,

but two areas on the left hand log show reduced amplitude on both

compressional and shear waves, indicating fractures. Notice that

waveform arrival time increases from left to right.

Reflections

from fractures cause changes in amplitude and travel time of the

main signal, and some waves arrive at later times, out of phase,

thus causing irregular interference patterns on the waveform.

Usually chevron patterns spanning several feet can be seen, indicating

reflections from near horizontal fractures. Chevrons are difficult

to see on older VDL presentations, but are much more obvious on

more modern logs, as seen on the example below. Chevron patterns are not necessary

as diagnostic tools. Low amplitude

is all that is needed. Other interfering effects, such as Stoneley

waves and rough borehole cause jittery patterns. Vertical fractures

create less disturbance.

Example of modern sonic log with Stoneley wave travel timea (left)

and VDL display with clear chevron patterns in limestone, indicating

fractures, and none in sandstone interval. Permeability (right) is

from Stoneley travel time.

Normal

presentation of older sonic amplitude log includes:

1.

3 ft. spacing borehole compensated compressional travel

time

2. 3 ft. spacing compressional amplitude curve

3. 5 ft. spacing variable density display of entire

wave train amplitude

4. 3 ft. spacing single receiver compressional travel

time

On

modern logs, the shear travel time and shear amplitude are recorded,

along with complete waveform displays and other diagnostic curves.

Stoneley wave travel time and attenuation are also shown. Colour

images of the waveform correlation amplitude or colour versions

of the waveform display are now common (see Chapter Three for

tool details).

Fractures

are indicated when:

1.

amplitude of compressional first arrivals is low

2. single receiver travel time skips or does not track

compressional travel time

3. high frequency chevron patterns are seen on variable

intensity display

4. amplitude of shear wave arrivals is low

Note

that single receiver travel time may vary, often indicating poor

tool centralization.

Circumferential sonic log for fracture detection

is a rare commodity

A

circumferential sonic log has also been developed but was not

widely available. Sound pulses travel around the borehole wall

and are attenuated most by vertical fractures, due to reflection

at the fracture surface. Few examples exist outside the well logging

literature. Both the sidewall and circumferential sonic rely on

waveform analysis for fracture identification. By alternating

between the two transmitters, four separate wavetrain or variable

intensity displays are created, one for each quadrant around the

hole.

Evaluation

of any acoustic measurement is still complicated because many

factors other than a fracture system can cause attenuation or

distortion of the wave. Washout zones should be identified before

a fracture interpretation is made because they give similar responses.

In some shales, the compressive amplitude is larger than the shear

amplitude, which again looks like a fractured zone. A gamma ray

or SP log should be used to identify such zones.

Dipole shear image log shows directional stress

- the Fast Direction is centered on

90 degrees (east - west) which

is also the maximum stress direction.

Dipole shear sonic logs offer many display options

On

the full wave or array sonic log, we can measure travel time and

attenuation of the compressional, shear, and Stoneley wave energies,

instead of merely the compressional energy as on conventional

sonic logs. On

the full wave or array sonic log, we can measure travel time and

attenuation of the compressional, shear, and Stoneley wave energies,

instead of merely the compressional energy as on conventional

sonic logs.

Shear attenuation may locate fractures or vuggy porosity Shear attenuation may locate fractures or vuggy porosity

These

attenuations result primarily from the large contrast in acoustic

impedance between the rock matrix and the fluid in the fractures

and in porosity. As compressional and shear waves traverse a fracture

their energies are significantly attenuated with the greatest

attenuation occurring to the shear wave. Remember that high attenuation is equivalent

to low amplitude. Attenuation is measured in decibels per foot

or per meter (db/ft or db/m).

Another

cause of energy reduction is poor acoustic coupling in zones with

vuggy porosity. This attenuation is due to acoustic wave scattering

as it is being transmitted through the vuggy porosity. Analysis

of acoustic energies must be supported by porosity information

to distinguish this situation. Acoustic energy is not severely

attenuated by normal intercrystalline porosity.

Waveform correlation map shows attenuation in

fractures

Suitable

processing of the digitally recorded waveforms can enhance the

visibility of fractures. One example is to plot the velocity cross

correlations to observe the compressional, shear, and Stoneley

energy on a time versus velocity crossplot. The peaks of the contoured

correlation amplitudes show where the sonic energy is located. Illustrated

above is a comparison of a fractured and un-fractured

zone, showing the loss of shear energy as fracture intensity increases.

Note also that the log curve disappears (see left hand track)

because no energy is being received at the tool. The gap in the

log can be drawn as a straight line. This loss of data is equivalent

to cycle skipping on older logs.

Another

method involves filtering the waveforms to enhance the chevron

patterns caused by mode conversion interference. This is similar

to F-K or velocity filtering on seismic data. The dipole array

sonic sharpens the chevron patterns naturally, due to the different

propagation path of the directional acoustic beam compared to

the omni-directional pattern of the monopole array sonic

Stoneley reflection coefficients, computed from

adjacent Stoneley velocities, also help to pinpoint fractures.

|