|

Log Calibrations

Log Calibrations

Calibrations are an integral part of any log. If they were

not run, or are now missing (or cut off the log), the

analyst should use extreme care in picking log values.

Standard calibrations for relatively modern logs (1960 to

present) are documented in service company manuals, which

should be part of your library. You will need dated versions

of these manuals as the current manuals will show only

current tools. This won't help for older logs in your files.

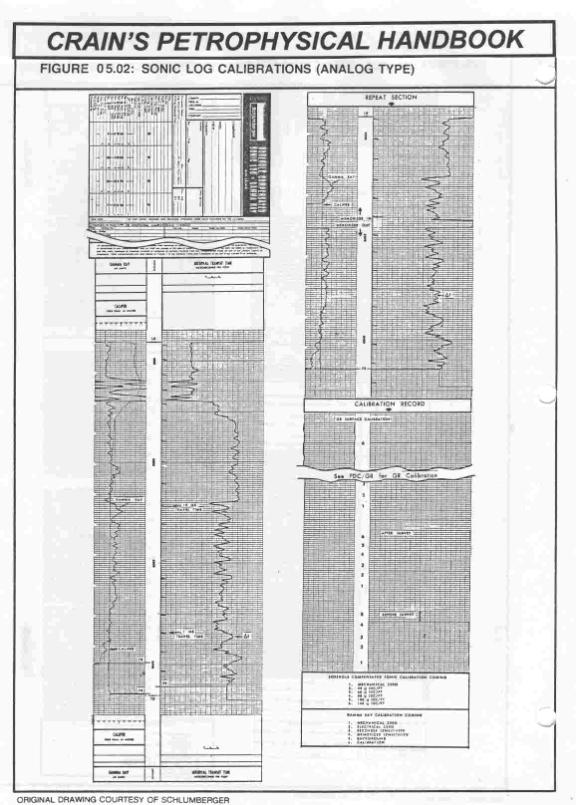

Two

calibration examples are shown below. The first is typical of

analog log recordings (1960 - 1975+/-) and the second is typical

of the digital log era. On analog calibrations, the calibration

steps for several log curves are shown on a log grid. For

digital logs, a computer printout will show the calibration

steps for various curves, as well as the permitted tolerance or

range of allowable values. Calibrations before and after the

survey, and in some cases shop calibrations are also attached.

Older logs (pre-1960) may have fewer, different, or no

calibrations shown. Calibrations for different service companies

vary slightly from each other, so be sure to obtain examples

from all service companies which you normally use.

Since

calibration details vary widely, it is impractical to publish all of

them in a handbook of this type. It is strongly recommended,

however, that you learn how to interpret and use calibration data,

such as those shown in the illustrations in this section.

Calibrations usually consist of low and high end points to define

the log scale, and intermediate points to define linearity of scale.

Primary calibration of a log usually occurs under laboratory

conditions or a test pit of known characteristics. Secondary

calibration is a method for carrying primary calibrations to the

service company field location by some device which simulates

the laboratory readings. These are usually called shop

calibrations. A third tier of calibration is a mechanism for

transporting shop calibrations to the field for use at each well

site.

For

example, a neutron log prototype is first calibrated in a test

pit with known rock type and porosity. Then it is immediately

run into a secondary calibrator of standard design, one of which

will be available at each major logging center around the world.

In the case of a neutron log, the secondary calibration is a

tank of particular dimensions filled with diesel fuel. The

readings in the secondary calibrator now constitute the main

source of calibration.

Periodically thereafter, each tool is placed in the secondary

calibrator, adjusted to read the correct response, and the field

calibrator is placed on the tool. The tool response to this

calibrator is then recorded. At each logging job, the tool is

readjusted to read the same value when in the field calibrator

environment. The field calibrator for a neutron log is a small

gamma ray source at a short distance from the neutron log

detector.

This

three stage process moves the primary calibration in the test

pit in Houston to each well logged by the tool. Some logs

require only a two stage calibration (such as induction logs)

and some only require one stage (such as spontaneous potential

or sonic travel time).

Calibrations performed before the log is run are called

Before-Survey Calibrations, and those run after the job are

called After-Survey Calibrations. Differences between Before and

After calibrations need to be accounted for only if the

difference is large enough to cause errors in the results of the

log analysis.

Even

though the logging engineer tries to perform calibrations

accurately and consistently, calibrations may be in error before

the survey starts or may drift from their set values due to

electronic problems. If these conditions prevail, the

calibrations are said to be shifted.

Several situations can arise if calibrations are clearly

shifted. Both before and after survey, calibrations may be off

by the same amount. Here, the log should be rescaled or a new

scale constructed to correspond to the calibrations. Most

computer aided log analysis software has a “block shift”

function to do this.

A

drift may occur between before and after calibrations. Here the

log must be rescaled at regular intervals to use up excess

drift.

For

example, assume a sonic log calibration showed the following:

| |

Low End |

|

High End |

| |

|

|

|

|

Before |

42 |

|

84

|

|

After |

43 |

|

82

|

|

Should have been |

40 |

|

80

|

|

If a

40 to 140 scale was used for the logged interval, and the log

was 3000 feet long, the following scales should be used:

|

Depth Interval |

|

Scale

|

| |

|

|

|

3000 to 2000 feet |

|

42 to 147 usec/foot |

|

2000 to 1000 feet |

|

42.5 to 145 usec/foot |

|

1000 to 0 feet |

|

43 to 143 usec/foot |

|

These values are created by linear interpolation or

extrapolation as required. Any log may be rescaled using linear

algebra. A computer can apply a continuous, linear or non-linear

shift as described by the user, providing the proper equation is

incorporated. Most computer aided log analysis software has a

“user-defined equation” function to do this type of

re-calibration.

All

induction resistivity and most laterologs logs should first be

translated into conductivity, rescaled, and then translated back

to resistivity. Most errors are in the sonde error setting,

which is a linear shift in conductivity, not in resistivity.

Calibrations may appear to be perfect, yet the log can read high

or low in comparison to other logs in the area. Checkpoints for

calibration shifts are the matrix base lines in clean,

non-porous limestone, dolomite, or anhydrite, shale base lines,

or overall position of the log curve with respect to another log

in the same or nearby well in thick shale beds with good

borehole conditions.

|