|

fractured reservoir CASE HISTORY

fractured reservoir CASE HISTORY

This example is from the Bent Horn Field, Cameron Island, in

the Canadian Arctic Islands. The field was produced briefly

during summer months, and a few tanker loads of oil were

taken from the Arctic to Europe each year until the field was

depleted.

Most

of the porosity for this reservoir is within the heavy mineral

zone, at the top of the log interval. Mineralogy here is quite

complex, containing barite, fluorite, quartz, calcite, anhydrite,

and clay in a relatively un-cemented form. A drillstem test recovered

these minerals along with oil. No drilling samples of this material

came to surface.

In

addition to production from the heavy mineral zone, there appears

to be some potential reservoir in the very low porosity carbonate

below. This limestone is near the front of the Bent Horn overthrust

fault, which strikes roughly east-west and dips (now) to the south.

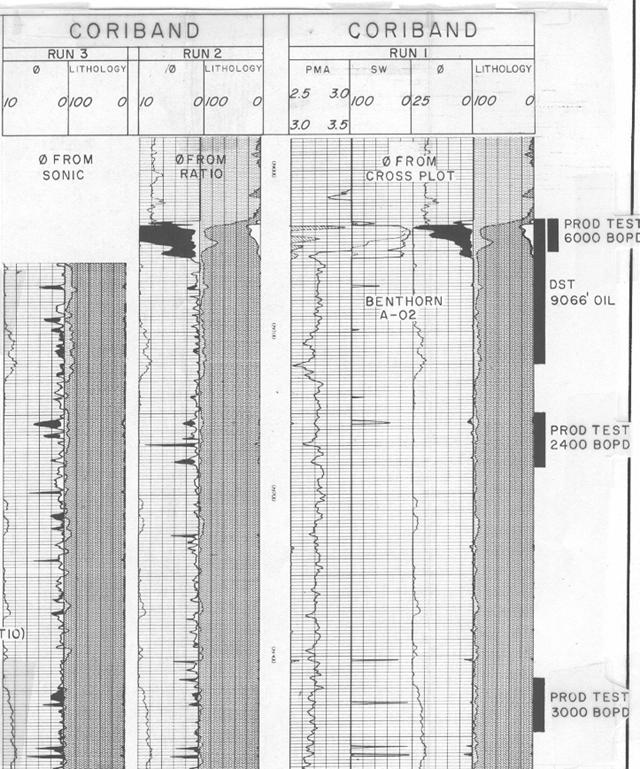

Porosity logs for Well A-02, Overthrust Example

Sonic amplitude and borehole geometry for Well

A-02, Overthrust Example

Dipmeter results and raw curves for Well A-02,

Overthrust Example

Computed lithology and porosity logs for Well

A-02, Overthrust Example

Displays

of all helpful logs (computed as well as original data) for well

A-02 are shown above. The initial indication

of fractures was from the caliper log (4-arm) reading oval hole

in certain zones, and from difficulty in keeping the sonic log

from skipping. The dipmeter correlation curves also show discrete

events on one or two curves that can be interpreted as high angle

(relative to the hole) fractures. Hole breakout on the caliper,

noisy density correction (not shown) and noisy density log all

point to fractures.

The

best dipmeter example is at 9198 (fracture dips north at 40 degrees)

and others at 9240, 9329 and 9355-9362. Some fracture planes are

so steep that dips were not computed by the dipmeter program due

to too low a search angle. The results using a higher search are

shown. In some cases, new (higher) dips are found and replace

lower, less coherent dips. In other zones no new data were found

and some were lost.

Other

zones of stress release fractures are indicated by the oval hole

indications on the borehole geometry log. The long axis of the

hole is perpendicular to the strike of the thrust sheet front,

and therefore parallel to the tension cracks caused by spreading

of the front. This orthogonal system of fractures would present

nearly vertical fractures at the borehole, and only those which

the dipmeter pads touched and which also depart locally from the

vertical will show up on the computed dipmeter.

The

sonic amplitude variable density log was run in open hole below

casing shoe at 10100, and in cased hole above this. Due to poor

cement bond, the VDL is not very helpful in locating fractured

zones through casing, but the portion in open hole (not shown)

indicates that the majority of the rock is fractured.

Sonic, borehole geometry and porosity logs

for Well O-51, Overthrust Example

Computed dipmeter and raw dipmeter for Well O-51, Overthrust Example

Computed porosity logs for Well O-51, Overthrust

Example

The

same logs for well O-51 are presented above. The amplitude VDL log is in open hole in this case. It

shows fracture zones at 7470-7506, 7636-7664 and 7920-8060. These

zones are confirmed by the dipmeter and the borehole geometry

log. Other smaller fractured zones are present on the log. The

distinctive "chevron" patterns on the VDL indicate semi

horizontal fractures, as opposed to the very regular "straight"

sections which indicate competent undisturbed rock.

The

limestone in this well dips to the east and the long axis of the

hole enlargement is roughly east-west, which is perpendicular

to the dip strike and parallel to the direction of hole deviation.

This is different from well A-02 where the hole

enlargement is perpendicular to strike, but also perpendicular

to the hole deviation direction. The "all quality" dipmeter

with the high search angle shows why some zones lose their coherent

dips when the higher search angle is used. The scatter of possible

dip answers is very large.

The

low porosity nature of the zone creates other interpretation problems.

The neutron porosity from the CNL (original log) is very low and

often a little behind zero. The sonic log (knowing we are in fairly

clean limestone) shows some porosity in the range of 0 - 4% on

both wells. This encouraged us to look

at computation methods that would utilize the more optimistic

porosity instead of the CNL (original) porosity.

Two

different approaches were taken. First, the Coriband program was

forced to use sonic log porosity (corrected for shale content)

by shifting density and neutron data above the highest sonic porosity.

Clay parameters were shifted the same amount, so that shale content

and matrix density are still computed correctly. Using the sonic

limit option then forces the program to use sonic porosity instead

of crossplot over the entire interval. These were dubbed "Sonic"

Coribands; results are shown in Figures 28.40 and 28.41.

The

second approach was to improve neutron porosity. This is done

by using the actual count rates recorded on tape and calculating

a porosity from each of the near and far count rates and from

their ratio. It is apparent from this data that the negative porosity

on the original log is generated by incorrect hole size corrections,

and completely distorts the true porosity picture. The log could

be shifted by about 1% to attain a more reasonable result, but

the logarithmic conversion from ratio to porosity is not handled

properly this way.

The

computed log which agreed most closely to the sonic porosity was

chosen, which in this case is the CNL porosity from count rate

ratios. Differences between sonic and neutron porosity are due

to secondary porosity, different response to vertical fractures,

and shale correction inaccuracies. No vuggy porosity was seen

in cores. Coriband was then run with the results shown. Saturation calculations can be improved by lowering

the formation factor exponent (M) to some value between 1.0 and

2.0, determined by the ratio of fracture porosity to matrix porosity.

This would have to be done on a zone by zone basis, and has not

been attempted in these wells.

The

A-02 well produced oil at rates up to 3,300 barrels per day through

perforations from each of several fractured low porosity zones

similar to the one at 9100-9130. It is possible that there was

communication behind casing to the main (heavy mineral) reservoir

at 9034-9054. There is also some reservoir volume in the fracture

porosity and in the low matrix porosity.

The

O-51 well tested a small amount of gas with water from comparable

rocks. It is structurally higher but obviously in a different

reservoir. The porous heavy mineral zone at the top is also missing.

|