Petrophysical Training

Licenses

|

HELIUM and INERT GAS BASICS

HELIUM and INERT GAS BASICS

The inert, or

noble, gases comprise

helium, neon, argon, krypton, xenon, and radon,

of which helium is probably the most important.

They

are formed during the natural

radioactive decay of elements such as uranium and thorium

within the interior of the Earth.

Helium is a valuable inert gas used in

commercial, military, and medical applications. It doesn't

burn or combine chemically with other elements.

It has

unusual cryogenic properties and is used in welding to cool

material adjacent to the weld and to cool the magnets in MRI

machines, as well as the magnets at CERN that helped

discover the Higgs boson. It also fills kids' balloons,

weather balloons, dirigibles, makes your voice

go squeaky when you breathe it, and helps space ships get

off the ground.

Helium and other

inert gases are often found

in conjunction with carbon dioxide and nitrogen, in wells that were originally drilled for

oil or natural gas as early as 1903 (in Kansas). This

discovery led to development, by the US government, of

a large helium resource stretching from Kansas through

Oklahoma into the panhandle of Texas. Pipelines, separation

facilities, and a large strategic reserve storage facility

were built during the 1950's and 1960's. Some processing was

privatized in the 1960's and private development was

permitted from the 1990's. Canada and Poland produced small

quantities in the 1960's and 1970's.

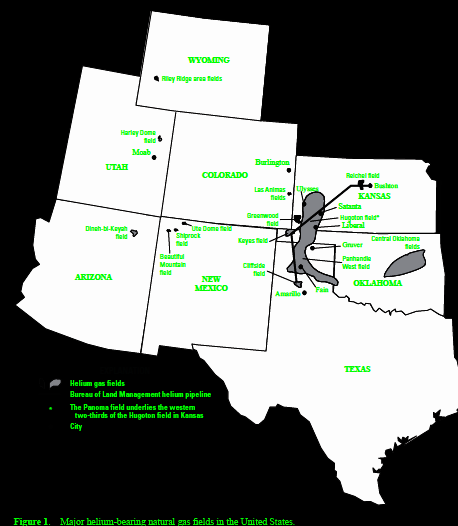

<==

Map of US helium reservoirs in mid-continent region. Image

courtesy US BLM.

Today, the USA produces about 55% of World supply, Algeria

and Qatar about 40%, the balance from a half dozen other

countries. The price is a little volatile, averaging US$

100+/- per thousand cubic feet (mcf), compared to natural

gas at US$ 4.00+/-.

Gas analysis reports

from helium bearing wells show high concentrations of CO2

or N2 with traces to several percent helium. Some have

hydrocarbon gases (methane, ethane, propane) in quantities

too small to allow the gas mixture to burn. A typical

analysis might show 5% He and 95% N2, or 5% He with 95% CO2,

or 5% He, 35% methane, with 60% N2. Wells with less than

0.5% He are probably uneconomic; an average producing well

in the USA has about 4% He.

The method used to separate helium

from a gas mixture is fractional distillation to

create crude helium, followed by low temperature liquefaction

to produce Grade-A 99.995% pure helium.

The major source of helium is

radioactive decay of uranium and thorium in basement rocks

or shales below potential reservoirs. Many helium producing

fields are associated with volcanic intrusions or deep-seated basement shears. Some helium may also come from

the primordial lithosphere through faults; this is the

lighter isotope of helium. Few isotope ratios have ever been

performed so the source is not precisely known in many

cases.

To trap helium in a reservoir

you need the same geological setting as for natural gas:

source rock, migration path, porous reservoir rock,

structural or stratigraphic trap, and a seal at the top of

the trap.

Migration path is usually

through faults or fractures but could be direct contact of a

reservoir with a source rock. Reservoirs are usually

sedimentary strata, but some igneous rocks may be porous and

permeable enough to hold helium.

Traps are often structural,

as drape over domes or anticlines. Strat traps are harder to

seal. The seal is more critical than for conventional oil or

gas. The helium molecule is about half the size of a methane

molecule so it can penetrate through smaller pores and

fractures than methane. This makes it difficult to contain

in samples and the seal on any trap must be lower

permeability than a similar trap for oil or natural gas. The

best seals are salt, salt plugged porosity, lava flows, or

very fine claystone (shale).

Production rates vary with reservoir quality, thickness, and

pressure. Many were overpressured and blew out in the early

days of helium exploration. CAUTION: If you find production

rates or production rate graphs, be sure to distinguish

between total flow rate of all gases versus helium flow

rates -- it isn't always clear.

If you are concerned about the environment, the inert gases,

other than helium, are vented to the atmosphere, including

CO2

and any hydrocarbons in the mixture. A few wells are

actually completed to capture CO2 or N2 for commercial

purposes, but most are not.

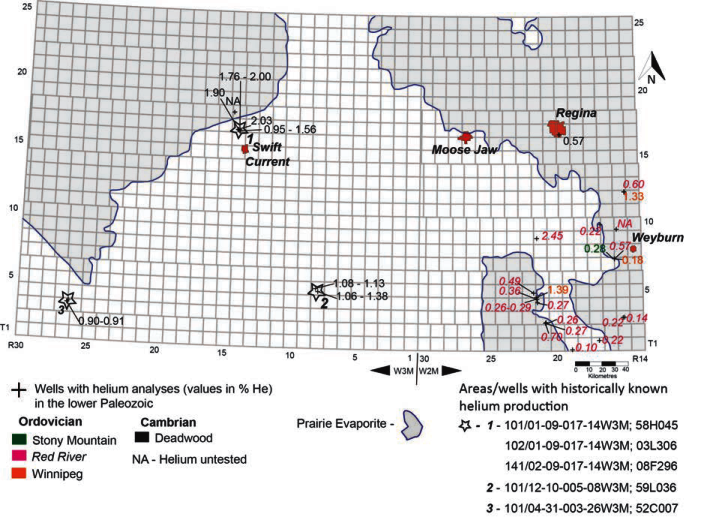

Distribution of all known helium tests in the lower

Paleozoic: Deadwood, Winnipeg, Red River and Stony Mountain

formations. Image from "Helium in Southwestern Saskatchewan", Melinda

Yurkowski, Saskatchewan Geological Survey, Open File Report

2016-1

LOG ANALYSIS IN HELIUM WELLS

LOG ANALYSIS IN HELIUM WELLS

Petrophysical analysis of inert gas reservoirs involves the

same steps as any other gas well: shale volume, effective

porosity, lithology, water saturation, permeability,

gas-in-place. There are a number of pitfalls in analyzing the well logs in

helium bearing zone in addition to the usual problems of

rough hole condition, highly variable mineralogy, salt

plugged porosity, and varying water resistivity which can

occur in any well. Here are the critical things that need to

be considered:

1. Old wells have minimum log suites (Electrical survey (ES),

possibly a microlog (MLC). By 1960 there may be a single

transmitter sonic log, by 1965 possibly a density log, and if

the God's are willing, a gamma ray and neutron log (GRN), probably

through casing. Each of these logs require special handling,

covered elsewhere in this Handbook, BUT ALSO subject to all

the concerns listed below.

2. All porosity models must be corrected for shale volume.

The gamma ray may permit this, but it should be calibrated

to XRD clay volume on at least a few samples.

3. Inert gases have no hydrogen, so in theory the neutron log reads zero

porosity. In air-drilled holes, there is no

mud-filtrate invasion, so neutron reads near zero. On

liquid-filled holes, neutron varies somewhat with the actual

water saturation in the invaded zone and depth of investigation

of the log. Clay volume, and

whether or not the gas column contains hydrocarbon gas in

addition to

the inert gases will increase neutron porosity In some wells, invasion is

deep enough for the neutron log to read a reasonable

porosity value. In other wells, the neutron log reads zero

or even slightly negative apparent porosity.

4. Sonic and density logs when transformed to porosity will read too high

a porosity due to gas effect, unless invasion is very deep

and residual gas in the invaded zone is negligible

(unlikely). Standard gas correction models will be needed,

calibrated to core porosity. Variations in matrix rock properties

will need to be controlled by sample and core description.

5. With the neutron log reading too low compared to a hydrocarbon gas

(possibly near zero), the standard gas corrected

density neutron complex lithology model for porosity may not

work well, giving a porosity that is too low. Some limited

experience in Saskatchewan suggests that invasion may be

sufficient to minimize this problem, but there was no core

data available to prove this. In other project areas, the

neutron reads zero and cannot be used as a porosity

indicator.

6. NMR porosity is unaffected by clay, mineralogy, or gas effects, so it

will give a reliable porosity in inert gas reservoir,

provided the borehole is not too rough and there is some

drilling fluid invasion. Some core analysis

control is comforting but less essential than for sonic and

density porosity.

7. The only lithology model that works properly in a gas reservoir is the

PE 2-mineral model. The PE curve was not common until the

1990's and may be missing in many wells drilled after that

date, so there may be no direct method to calculate

mineralogy. Sample and core descriptions are a necessity to assist

in understanding the mineralogy and the higher quality

reservoir faces.

8. After a porosity algorithm has been calibrated to core, the deep

resistivity can be used to calculate water saturation,

provided the correct RW regime can be identified. This

allows the calculation of total gas in place. Multiply by

helium fraction to obtain helium in place.

9. If salt plugging is present, it might be possible to identify it by

very high resistivity and very low neutron and/or NMR porosity. The

efficacy will depend on whether or not the drilling fluid

has dissolved the salt in the zone investigated by the

neutron log. Sonic and density porosity may be lower than

non-plugged intervals due to the different log response of

salt and gas. Results may still be ambiguous. When identified, salt plugged zones are flagged and porosity set

to zero.

10. Once porosity and saturation are calculated, and salt plugged

intervals are flagged, permeability can be calculated from

the usual Wyllie, Timur, or Lucia methods. An estimate of

total gas deliverability at initial unstimulated conditions

is possible based on the sum of permeability thickness

values. There is a large possible error in this result as

natural fracture permeability is not included.

11. Helium concentration

CANNOT be calculated directly from any well log result.

12.

Inert gas wells are among the most difficult to quantify

using well log data. Core analysis data and sample

descriptions, with a little help from XRD mineralogy data,

can make the job a little more

conclusive. Commercial software will most likely fail to give an accurate

estimate of porosity unless you add some user-defined

equations to account for the peculiar gas effect

caused by inert gases..

LOGging program for inert gas wells

LOGging program for inert gas wells

While we are stuck with the log suite in existing wells, we

can run an appropriate program today that will give optimum

results. The recommended suite is:

1. array induction or array laterolog with SP and gamma ray. (In

air-drilled holes, laterolog cannot be run).

2. density neutron with PE and spectral gamma ray.

3. nuclear magnetic resonance log with gamma ray.

4. array sonic log for correlation with older wells and to assist seismic

interpretation.

5. resistivity image log to assist in facies description, and trap

and seal definition.

Items 3 and 5 are needed only from TD to 100 meters above

the zone of interest.

Gas log, conventional or drilled sidewall cores, close

spaced sample description, and XRD mineralogy and bulk clay

are strongly recommended.

LOG ANALYSIS EXAMPLES IN HELIUM WELLS

LOG ANALYSIS EXAMPLES IN HELIUM WELLS

ANCIENT LOG EXAMPLES WITH NO QUANTITATIVE PETROPHYSICAL

ANALYSIS

ANCIENT LOG EXAMPLES WITH NO QUANTITATIVE PETROPHYSICAL

ANALYSIS

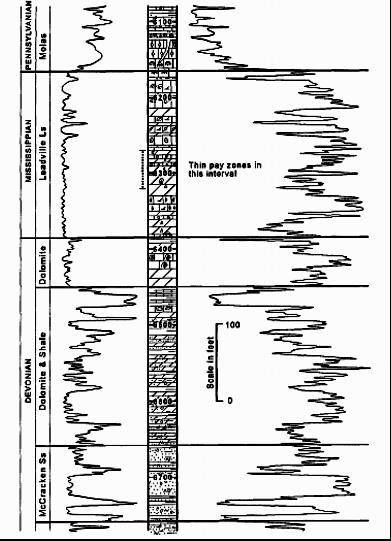

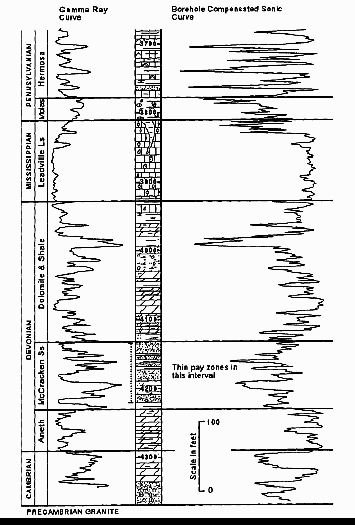

These two examples are from "Oil and Gas; and Helium

Production Potential of Oil and Gas Assets in Navajo County,

Arizona" by Olufela Olukoga, prepared for Blackstone

Exploration Company Inc.

Left: Ancient gamma ray neutron log in

helium bearing reservoir in the Tohache Wash Field. Gas in

the Mississippian was 6.03% helium. Cumulative production

was 385 Bcf total gas. Neutron deflections to the right are

low porosity OR inert gas. Right: Borehole compensated sonic

log in Kerr-McGee #2 Navajo-C well showing the stratigraphic

position of the helium-bearing reservoir in the Dineh bi

Keyah Field. Gas in the Devonian ranges from 3.11% to 6.23%

helium and averages 4.83% helium and produced 1.4 Bcf total. High sonic travel time is high porosity or shale.

MODERN PETROPHYSICAL

ANALYSIS EXAMPLES

MODERN PETROPHYSICAL

ANALYSIS EXAMPLES

These examples are from wells that have tested or produced inert gas with helium in economic quantities.

The analyses were performed for North American Helium Ltd

and are reproduced here with their permission.

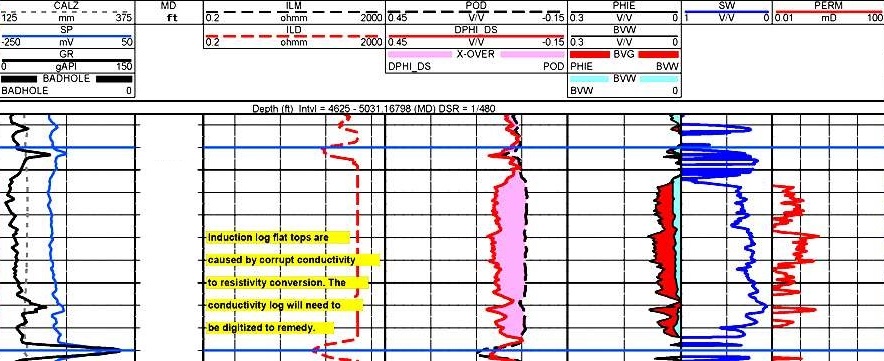

EXAMPLE 1: Air-drilled Inert Gas Well

Left hand tracks contain gamma ray, deep resistivity, density, neutron

(with gas crossover shaded pink) curves. Right hand tracks

show calculated effective porosity (with inert gas volume

shaded red), water saturation, and permeability, Neutron log

reads zero porosity since inert gas has no hydrogen content

and there is no invasion from a liquid borehole fluid. SP,

shallow resistivity, and sonic are missing as they cannot be

recorded in an air-drilled hole.(Image courtesy NA Hrliun).

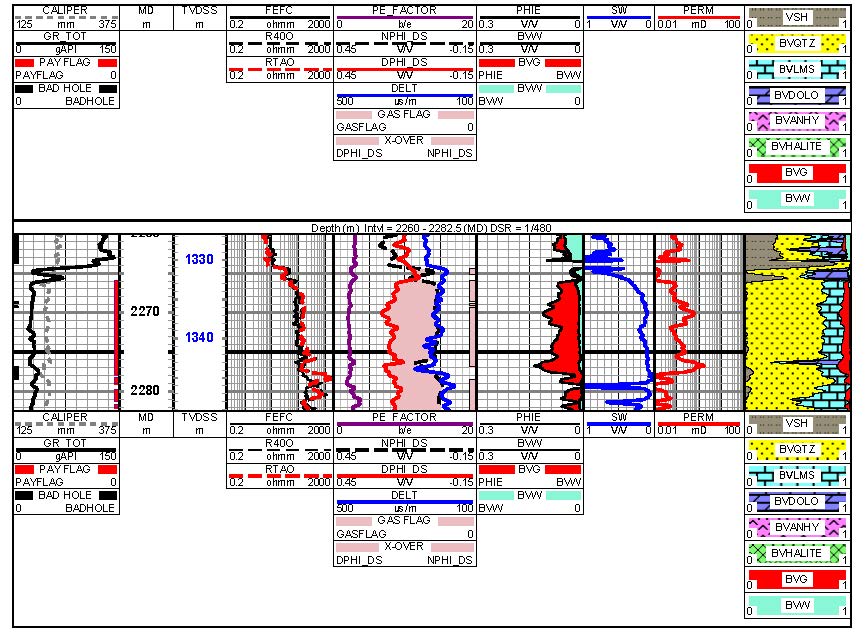

EXAMPLE 2: Liquid-filled Borehole

Left hand tracks contain gamma ray, deep and shallow

resistivity, density, neutron (with gas crossover shaded

pink), PE, and sonic curves. Neutron log responds to

invasion water but may read a bit low due to residual inert

gas in the invaded zone. Right

hand tracks show calculated effective porosity (with inert

gas volume shaded red, water saturation, permeability, and lithology analysis.

(Image courtesy NA Hrliun).

|

|