|

Lithium BASICS

Lithium BASICS

Petro-lithium is present in oilfield produced water

and in moderate to highly saline water zones in sedimentary

basins. Well logs cannot identify lithium in oilfield brines

(at least not yet) but they do tell us a lot about the water

salinity, pore volume filled with that water, and other

pertinent information about the reservoir or aquifer. This

article describes near surface and deep sources of lithium,

how it is extracted from brines, as well as the mining

technique which until recently was the major source of the

world’s lithium.

Lithium (Li) is a soft,

silvery-white alkali metal. Under standard conditions, it is

the lightest metal and the least dense solid element. Like

all alkali metals, lithium is highly reactive and flammable,

and must be stored in vacuum, inert atmosphere, or inert

liquid such as purified kerosene or mineral oil.

It never occurs freely in nature, but mostly in ionic

compounds, such as pegmatitic minerals (spodumene, and to

lesser extent, amblygonite, lepidolite,

and petalite), which were

once the main source of lithium. Extraction was a classical

hard rock mining operation in which the ore was heated,

crushed, and leached to obtain stable lithium-rich

compounds.

Since about 1990, surface and near-surface brines in lakes,

playa deposits, and salt flats have become major sources of

lithium compounds.

Soon oilfield produced water, oilfield water zones, and

medium temperature geothermal projects will be capturing

lithium from these higher salinity water flows.

Lithium and its compounds have many industrial uses

including heat-resistant glass and ceramics, lithium grease

lubricants, flux additives for iron, steel, and aluminum

production, and lithium or lithium-ion batteries. These uses

consume more than three-quarters of lithium production

(2020), and will continue to increase rapidly as the World’s

vehicle fleet is electrified..

Lithium reserves and resources are measured in

metric tonnes Li metal equivalent. Hard rock ore grade is

reported in percent Li2O, similar to potash ore grade in

percent K2O. An average ore grade for a hard rock mine might

be 2.4%. In brines, quality is graded in parts per million (ppm

or mg/liter) Li+ ions – 500 ppm represents a fairly high

concentration in an oilfield brine or a moderate value for a

near-surface brine deposit.

USGS and other studies show the lithium resource is

available for projected needs but extraction may lag demand.

Petrophysics, with other geosciences, will play a major role

in quantifying reservoir volumes, water quality, and flow

capacity that will help to assess the economics of these

projects.

LITHIUM EXTRACTION FROM

HARD ROCK ORES

LITHIUM EXTRACTION FROM

HARD ROCK ORES

Ore from hard rock mining

of pegmatic minerals is heated to 1200K and crushed, The

minerals are combined with sulphuric acid and sodium

carbonate which causes the aluminum and iron to precipitate

from the ore. Sodium carbonate is added to the lithium

products which causes the lithium to precipitate out in the

form of lithium carbonate (Li2CO3).

Hydrochloric acid is added to the Lithium carbonate to form

lithium chloride.

LITHIUM EXTRACTION FROM

SURFACE BRINES

LITHIUM EXTRACTION FROM

SURFACE BRINES

A large fraction of the

world's current lithium is produced by evaporation of brine

in ponds. This process is time-consuming, but is also

inexpensive compared to other methods. The salt-rich waters

are pumped from the ground and start to evaporate through

solar energy. This process can take several months, up to

two years. First, potassium is harvested. Then when the

lithium compounds reaches a suitable concentration, they are

harvested and brought to a plant. Unwanted waste is filtered

out, then the concentrate is treated with sodium carbonate,

to create lithium carbonate. Finally, the unwanted waste is

pumped back into the ground.

Seawater has only 0.2 ppm Li so it is not considered a

credible source of economic lithium.

LITHIUM EXTRACTION FROM

DEEP BRINES

LITHIUM EXTRACTION FROM

DEEP BRINES

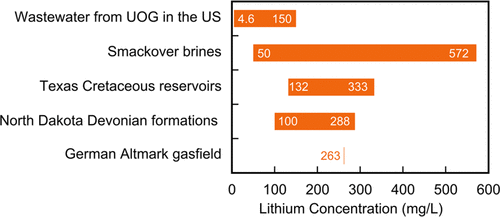

Lithium from oilfield

produced brines (50 – 500+ ppm Li+), co-produced with oil or

natural gas, and from deep high salinity oilfield water

zones is in its infancy but is much more environmentally

friendly than destroying salt flats or pegmatic mountains.

Note that oilfield produced water is sometimes called

oilfield waste water, not to be confused with municipal

waste water, which is a very different thing. Oilfield waste

water is injected back into the reservoir where it came

from; municipal waste water may or may not be treated and is

fed into rivers or oceans.

Co-production of lithium with medium temperature geothermal

energy projects in sedimentary basins looks very attractive.

As in the oilfield case, the water is from deep saline zones

and is already being pumped to a disposal well.

Lithium concentration of various produced oilfield brines (Kumar et al

2019)

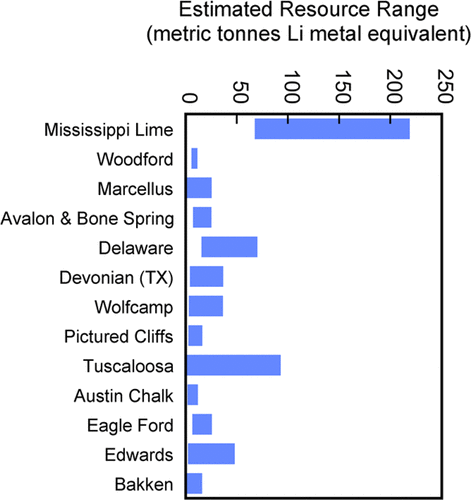

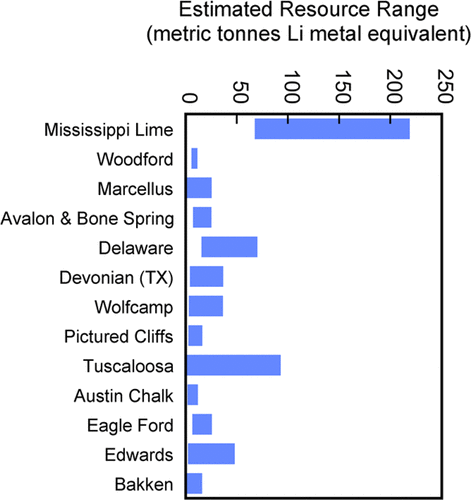

Lithium resources of various produced oilfield brines (Kumar et al

2019)

Fox Creek and Valleyview in Canada have 362 000 and 385 000 metric

tonnes of Li metal equivalent, respectively, while the Smackover

Formation in the U.S. has 750 000 metric tonnes.

Lithium may be extracted from the oilfield produced water and

geothermal water flowing to the disposal well using an adsorption,

membrane-based processes, and electrolysis-based

systems. These and other approaches are in the pilot project stage

(2022).

Extraction of lithium from oilfield and geothermal brines enables

domestic production without relying on South American sources and

Chinese refining.

Apparently 100 ppm Li+ can make extra cash, since the water is

already being separated and pumped to the disposal site. Repurposing

deep wells that have reached end of life as oil or gas wells will

need higher concentrations of Li+ to pay out the pumping costs.

Time to drag out all those old water chemistry reports, or to take

new water samples from produced water to see what we own.

There will probably be some mineral-rights and regulatory issues to

resolve with various agencies and land owners. Further, some

innovative approaches are needed to test saline water zones for

lithium concentration before a well is prematurely abandoned.

Transforming unwanted oil wells into “green energy” sources is very

appealing.

REFERENCES

1. Lithium Recovery from Oil and Gas Produced Water

Amit Kumar,

Hiroki Fukuda, Alan Hatton, and John

H. Lienhard

https://doi.org/10.1021/acsenergylett.9b00779

2. Lithium Technical Data

Various Wikipedia Pages

|