|

Metallic minerals

Metallic minerals

This article reviews conventional borehole logs that are

useful in the mining sector, followed by a more detailed

discussion of some less familiar special-purpose logs with

specific application to metallic mineral exploration. Both

have a significant part to play in the evolving quest for

greener energy solutions, in finding commodities, and

solving environmental issues.

There is much common ground in the geoscience of mineral and

petroleum exploration and development, but also some

fundamental differences. For example, mining operators rely

on drill-cores more than borehole logs. Mine integrity and

the safety of underground workers is part of the reason.

Also pertinent is that miners need to know the mineral

composition of an ore body with more precision than logging

tools could offer. Regardless, logs and cores are used in

both industries, so we will explain the differences and

overlaps in these two communities.

Decarbonizing by electrifying the World is a monumental

task; a variety of reports claim that metallic mineral

outputs may not keep pace with demand for power grid

upgrades or water and wind turbine construction, let alone

all those electric vehicles. Deeper new mines and expansion

of older mines are urgently needed; leading to increased

demand for geoscientists and engineers capable of locating,

detailing, and operating these new mines. Failure to match

mineral supply to expected demand will mean failure of any

plan for a “net-zero” economy.

Hopefully, the reader will be inspired to consider new,

cooperative ways to improve our mineral outputs and meet the

tough challenges ahead.

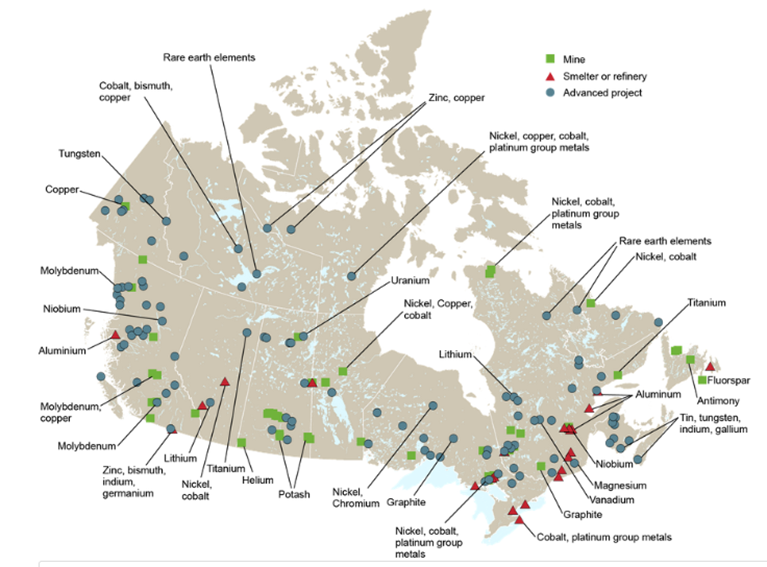

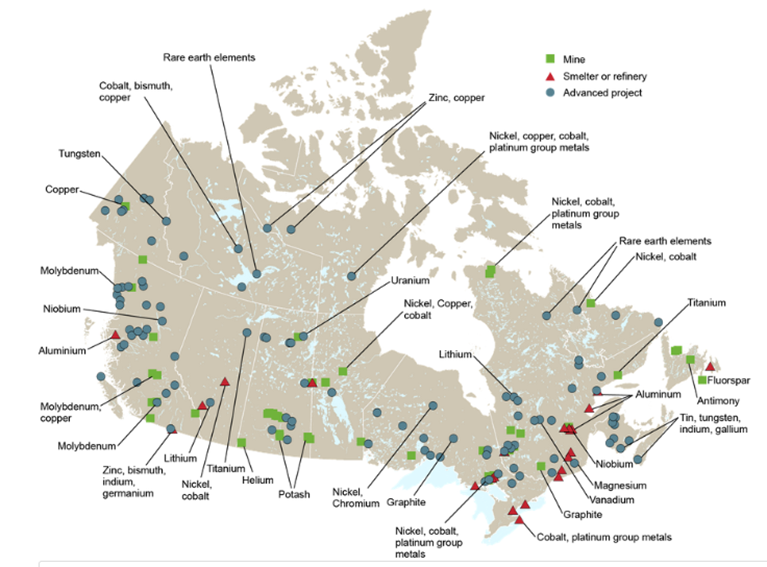

Location of Mineral Deposits in Canada, including Rare Earth

Elements

borehole logging IN the Mining ENVIRONMENT

borehole logging IN the Mining ENVIRONMENT

For

clarity, we will refer to logs run for the mining industry as

“borehole logs” and those for the oil and gas industry as “oilfield

logs” or “well logs”, even though the guiding physical principles

are the same for both.

It is difficult to make direct comparisons between oilfield logging

tools and borehole tools. Many contractors developed their own

tools and probes are often customized to suit a particular

exploration challenge. The result is less standardization. Some

contractors offer a complete range of services from data acquisition

to mapping, while others specialize in smaller projects, by

supplying tool rentals. Happily, many of the borehole log names are

well-known to the oilfield log analyst, as the measurement

principles are the same. Acoustic, gamma ray, spectral gamma ray,

density, neutron and electrical logs are common to both industries.

In general, borehole tools are smaller and have reduced temperature

and pressure ratings (eg., 20 mPa and 80 degC) compared to oilfield

tools (100 mPa and 150 degC). However, many standard oilfield tools

are available in slim-hole versions and are quite suitable for

mineral borehole logging. A typical slim-hole gamma ray tool is just

42.9 mm (1-13/16 in) in diameter and approximately a meter long,

compared to a mineral service contractor’s GR tool at 38 mm diameter

and length of 0.63 meters.

There is a striking difference in scale between borehole logging

operations for mining, and that for petroleum. Mining drill-rigs

are typically portable (even heli-portable), and boreholes are

drilled to recover core or, in the case of reverse circulation (RC)

drilling, to recover samples. Boreholes can be blasted or drilled,

with logging equipment typically consisting of 3 components: a data

acquisition system to collect data from the downhole probe, a winch

to deploy the probe into the borehole, and the downhole probe

itself, which might be standalone or stackable.

borehole logging and coring Programs

borehole logging and coring Programs

The primary

logging measurements would be one or more of the following:

electrical conductivity (or resistivity), magnetic susceptibility,

natural gamma radiation (total and spectral), acoustic velocity (or

travel time), bulk density, and more recently, induced gamma ray

spectroscopy to identify particular metallic elements in the host

rock.

Specialty logs such as magnetic susceptibility, induced

polarization, or high resolution temperature logs may be used as

well.

Terraplus in Canada, offers auxiliary equipment such as video

inspection systems, borehole geophones, and hydrophone arrays, plus

ground penetrating radar antennas for single hole investigation and

cross-hole tomography. In the USA, Century Geophysical, among

others, provides a wide variety of tools for the mining industry.

The service providers are usually local contractors or the mining

company itself.

Geological Survey of

Canada and the US Geological Survey have

also developed their own logging tools, mostly used in mineral

reconnaissance surveys.

The mining

industry relies heavily on coring, core description, and lab work

for its geotechnical and geomechanical logs. Very detailed

lithology, stratigraphy, and structure are annotated on these logs,

as well as detailed notes on grain size, texture, and rock fabric.

This information is entered into 3-D modeling software. Rock

strength, discontinuities, faults, and fractures are carefully

mapped into the model. Borehole logs and core photos are added to

complete the 3-D display.

The model is constantly updated throughout the feasibility, design,

development, operational, and expansion phases of a mines long

lifetime. The integrity of the mine and the safety of the workers

depend on the accuracy of this model. No shortcuts allowed!

The coring and logging procedures described above are also used to

study geomechanical properties for dams, tunnels, highways,

foundations, and many other large construction projects.

SPECIALIZED Logging TOOLs FOR MINING APPLICATIONS

SPECIALIZED Logging TOOLs FOR MINING APPLICATIONS

This

section describes some of the specialized borehole logging tools

used in mineral exploration and development, including some new or

experimental tools that may solve some problems that conventional

tools cannot. With the exception of induced gamma ray spectroscopy

and limited use of induced polarization, these tools are not used in

oilfield situations.

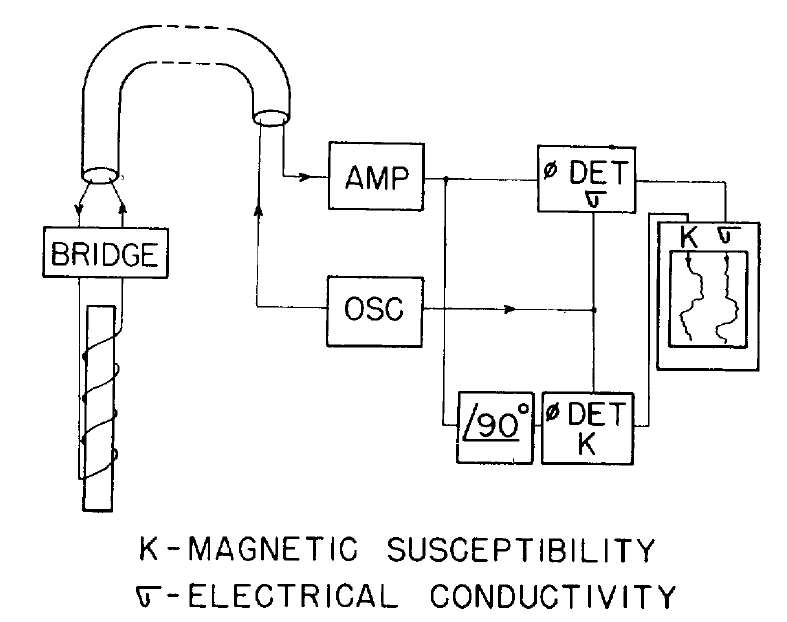

INDUCTION / Electromagnetic Susceptibility Logs

INDUCTION / Electromagnetic Susceptibility Logs

Electromagnetic methods are familiar to the oil and gas

sector as induction logs. They were developed due to the popularity

of oil-based mud and air-drilling systems. There was early

recognition that having control data from a borehole instrument

would verify the interpretation of surface magnetometer studies.

(5)

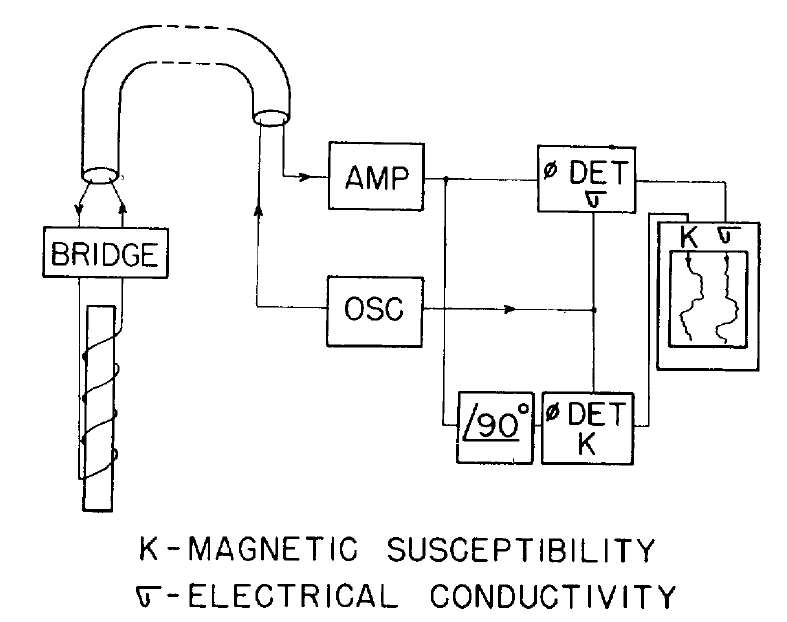

In the mining sector, a probe consisting of a transmitter and

receiver induces current flow in the formation creating a primary

magnetic field. This causes eddy currents to flow in a continuous

circular distribution centered around the borehole axis. These eddy

currents are proportional to the formation conductivity, and they in

turn generate a secondary magnetic field, which induces an

alternating voltage in the receiver coil. In the resulting voltage

vector, the magnitude and phase are a function of the conductivity

of the formation. Phase

sensitive detectors separate the signal into its resistive (from

conductivity) and reactive (from magnetism) components so that the

electrical conductivity and magnetic susceptibility are recorded

independently and simultaneously.

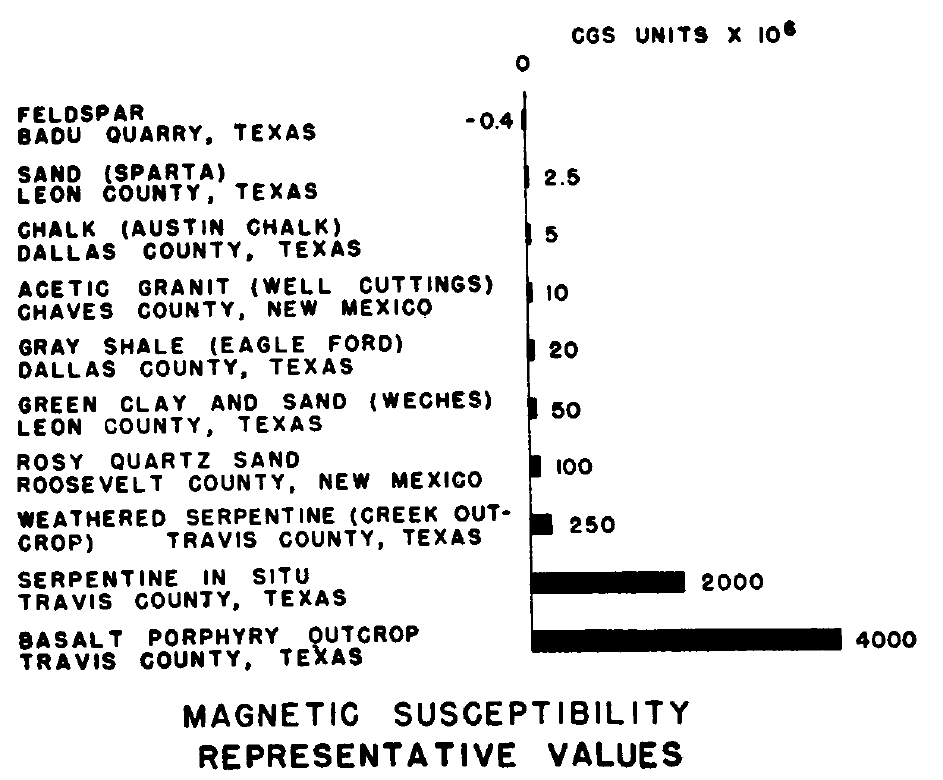

The log displays magnetic susceptibility, (c

(chi)),

either in cgs^106 or SI units, and conductivity in mmho/m

(mS/m). Chi

relates a material’s magnetization M, to the strength of an applied

magnetic field H, using the equation M = Chi * H.

Simplified diagram of Electromagnetic tool showing phase shift

between conductivity and susceptibility.

(5)

Magnetic

anomalies may be caused by primary igneous or sedimentary processes,

or by secondary alterations where magnetic material is either added

or removed. Conductivity measurements can be used to detect and

correlate conductive sulphides. Magnetic susceptibility can directly

detect iron ore and be used to characterize and correlate sulphide

units. Main benefits of borehole electromagnetic methods are their

indifference to borehole rugosity and their ability to make

measurements through PVC casing.

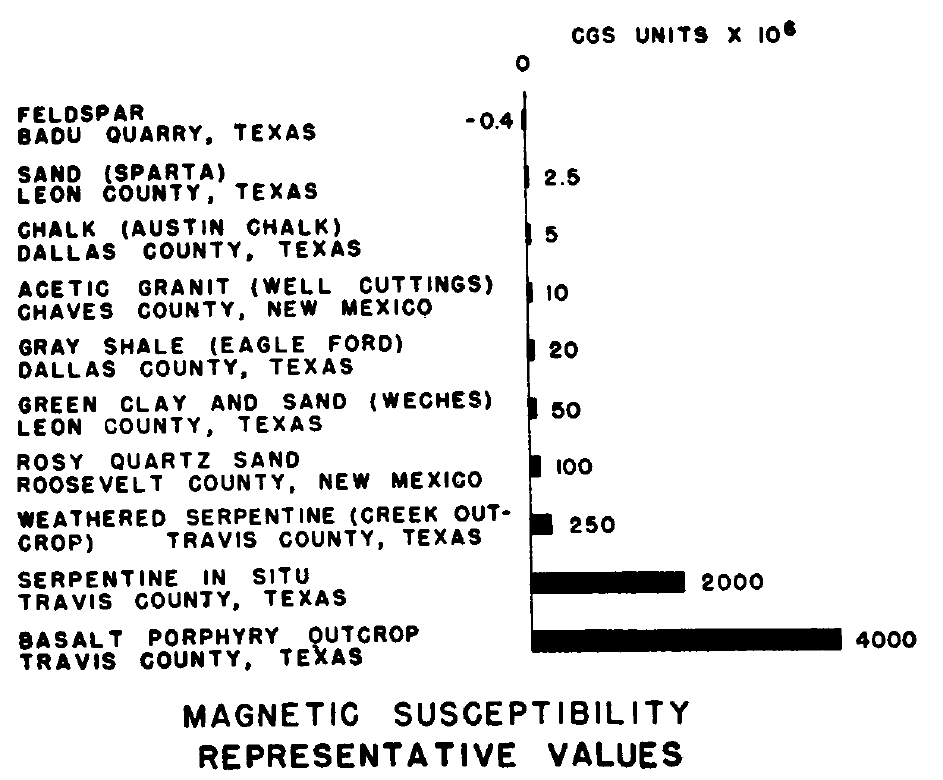

Values of Magnetic Susceptibility in various formations, in cgs

^ 106 units.

(5)

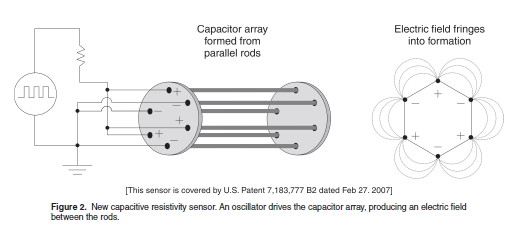

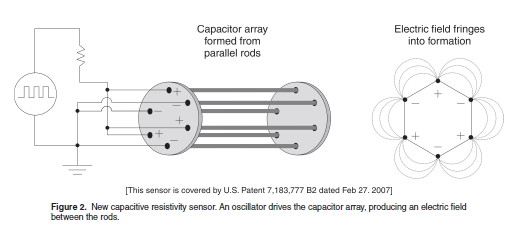

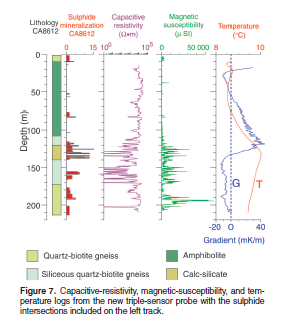

In 2011,

the Geological Survey of Canada sponsored development of a new

triple sensor probe (TSP), which combined an electromagnetic

component to measure magnetic susceptibility, alongside a capacitive

resistivity sensor and high-resolution temperature device. The TSP

allowed three measurements to be taken concurrently in a single

logging run. The resistivity component was re-designed to use a

capacitor array formed from parallel rods instead of galvanic

contact electrodes which are useless in PVC cased or air-filled

holes. An oscillator drives the capacitor array to produce the

electrical field. This tool combination has found success in

delineating base metals such as Cu-Pb-Zn massive sulphides and

nickel-sulphide deposits. (6)

Figure

4: Diagram of Capacitor Array for TSP logging tool

(6)

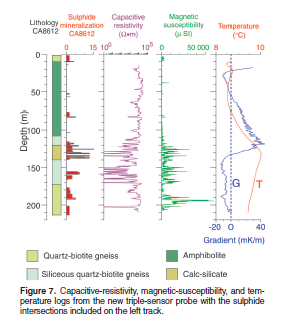

Results from a TSP log showing a lithology track, sulphide

occurrences, resistivity, susceptibility and temperature.

(6)

Induced Polarization Logs

Induced Polarization Logs

Induced

polarization is a method to image the conductivity and chargeability

of porous rocks. It is most commonly used to delineate disseminated

sulphides within a host rock. When a charging current is turned off,

voltage decays over a finite time (discharging) back to zero. When

the current is turned on, voltage builds up over a finite time to a

maximum applied value. The current is for a time stored in the

ground (capacitance), causing some material to become polarized.

This phenomenon is called induced polarization. (7)

Century

Geophysical has a multi-parameter Series Induced Polarization

logging tool for hard rock mining and uranium exploration. It

records SP, a single point resistance, and induced polarization,

with optional natural gamma ray. The tool features a 16 and 64

array electrode spacing, passing an alternating current through the

formation, resulting in a measurement of chargeability. This

lightweight tool is 51 mm. OD and ~2 m. long.

|

Material Type

1 % Sample Concentration |

Chargeability (msec) |

|

Pyrite |

13.4 |

|

Chalcocite |

13.2 |

|

Copper |

12.3 |

|

Graphite |

11.2 |

|

Chalcopyrite |

9.4 |

|

Galena |

3.7 |

|

Magnetite |

2.2 |

|

Malachite |

0.2 |

|

Hematite |

0 |

Chargeability times for various rocks and minerals.

(7)

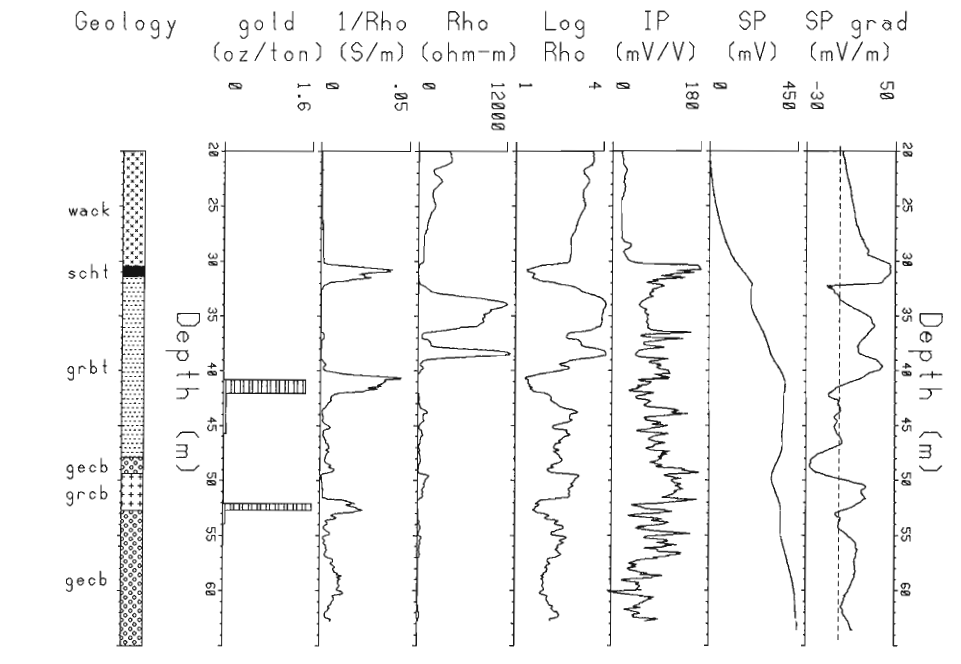

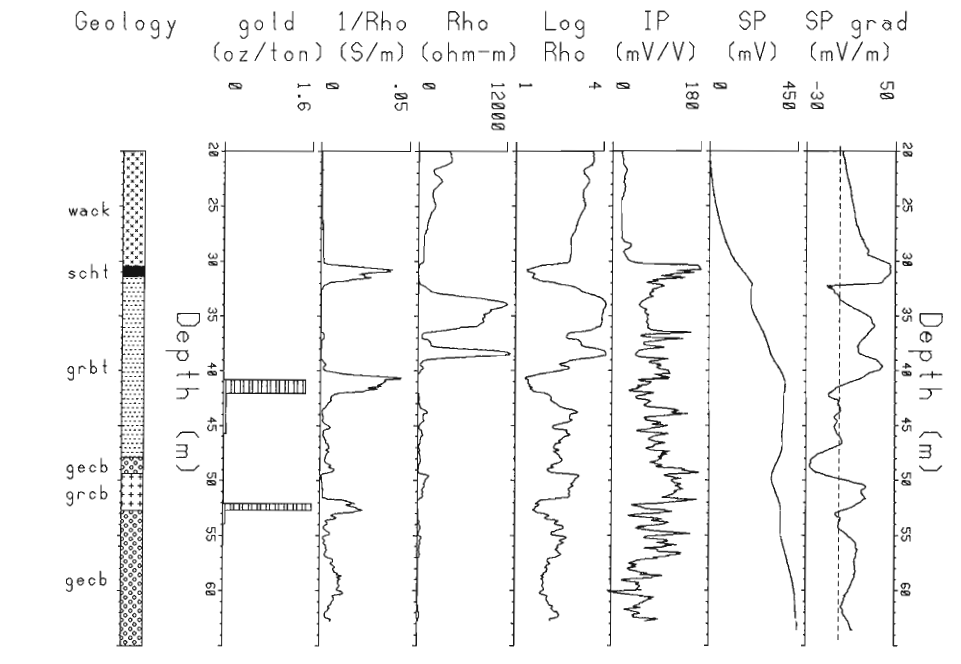

In 1986, a

Canadian study ran IP logs along with temperature, resistivity, and

SP logs to evaluate IP’s usefulness in finding gold associated with

pyrite within a volcanic host rock. The combined logs were very

good at defining a marker bed of graphite-schist but proved more

ambiguous for the gold. The study showed the benefits of

multiparameter logging acquisitions for delineating highly altered

rocks, but a statistical approach to the

complex dataset needed further development. (8)

Comparison of Gold Assay, track 1 with IP response, track 5.

(8)

Induced Gamma Ray Spectroscopy

Induced Gamma Ray Spectroscopy

Induced

gamma ray spectroscopy logs, sometimes called activation logs,

measure the concentration of specific elements in the rock. In

oilfield use, the elemental yields are transformed into minerals

using a least squares algorithm to create a lithology log

presentation. Capture cross section (Sigma) and neutron porosity

(TPHI) are the other primary measurements, carried forward from the

earliest days of the pulsed neutron log. These two measurements

allow us to calculate porosity and water saturation in cased holes.

In mining

exploration, this technology has lagged behind resistivity and gamma

ray methods, mainly due to mining’s reluctance to handle radioactive

sources in the field. This is not surprising when the logging unit

could be the back of a geologist’s truck, plus developing such a

specialized tool could be prohibitively expensive.

Pulsed neutron methods were being used in mining in 1972, initially

to detect copper. The development of a delayed-fission neutron

system, by Century Geophysical Corp. was found to be superior for

uranium prospecting. (9)

More

recently, CSIRO in Australia has developed a Prompt Gamma Neutron

Activation Analysis (PGNAA) (10), a spectrometric nuclear

logging tool which results in a real-time downhole assay of elements

in the rock. Similar in principle to the LithoScanner and

Pulsar tools from the petroleum industry, the PGNAA bombards the

formation with fast neutrons and measures the gamma ray spectra

generated by the nuclear reaction. The gamma rays’ intensity and

energy create unique photopeak signatures, proportional to the

elemental composition of the rock. The tool samples the surrounding

rock to a depth of ~50 cm, generating in situ rock mass density and

estimates of elemental composition. A main advantage over the core

assay method is continuous depth coverage (no lost core!) plus

deeper depth of investigation. The tool is calibrated to the

expected mix of mineralogy and source/detector configuration is

designed specifically for that expected lithology.

The PGNAA

tool may feature either chemical or pulsed neutron sources and uses

either BGO (NaI(T1) or CsI

detectors.

The measurement range is slightly larger than oilfield tools at 0.5

to 11 MeV. The tool has several shields, to protect the detector

from fast and thermal neutrons escaping from the sample, and from

the primary gamma rays generated by the source. A biological shield

is built-in to minimize radiation risk to logging personnel.

The tool

quantifies elements such as Si, Fe in iron ore, Mn in manganese ore,

Cu, Ni, Ti, Cl, and many more. A benefit is that the large range of

discoverable elements makes it possible to quantify “penalty”

elements, which lower the grade of ore, cause smelting problems, or

introduce unwanted attributes in the finished product, such as

brittleness to steel.

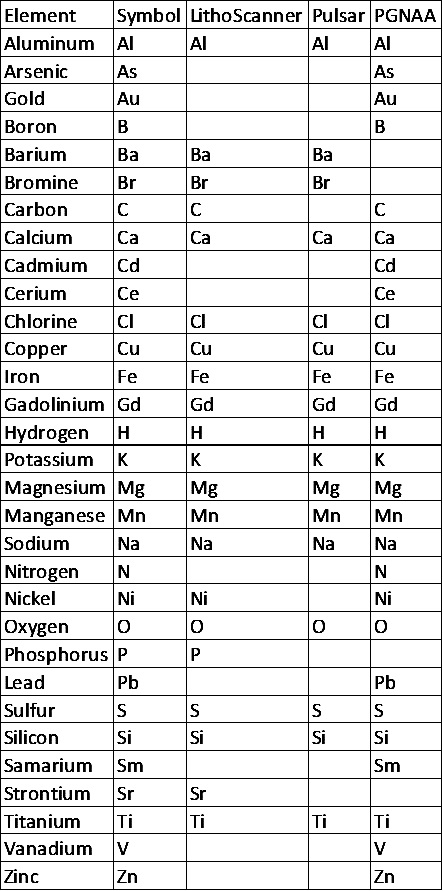

In contrast, oilfield tools such as Schlumberger’s open-hole

LithoScanner or cased-hole Pulsar use a pulsed neutron generator.

LithoScanner focuses on the element sets common to petroleum

environments (silicates, carbonates, unconventional), with just 4

metals of interest to mining: Cu, Gd, Ni and Ti. Although the

PGNAA’s element sets are geared to hard rock environments, the tools

have 15 elemental outputs in common

The Pulsar log is a slim-hole 42.7 mm (1-11/16 in), 5.5 m long

alternative to LithoScanner. Pulsar provides a similar suite of

elemental logs (with additional elements on request) and an accurate

measure of TOC. Its main advantage is the fast neutron cross

section (FNXS), a measurement that, being independent from

resistivity-based calculations, is a fool proof gas indicator. The

results are very helpful in monitoring CO2 storage, CO2 miscible

floods, and helium reservoirs. In mining boreholes, it may provide

information suitable for correlation and quantification of massive

sulphides.

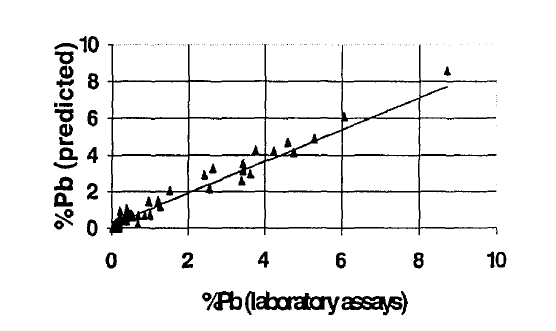

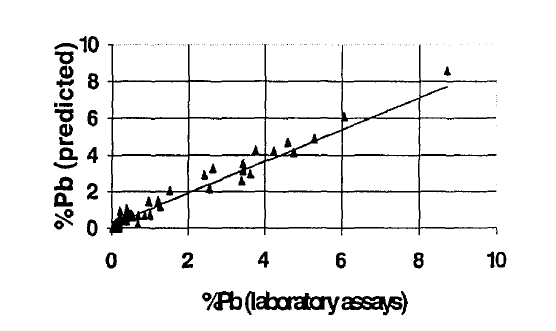

Comparison of laboratory assays with SirologTM PGNAA

values for lead.

(10)

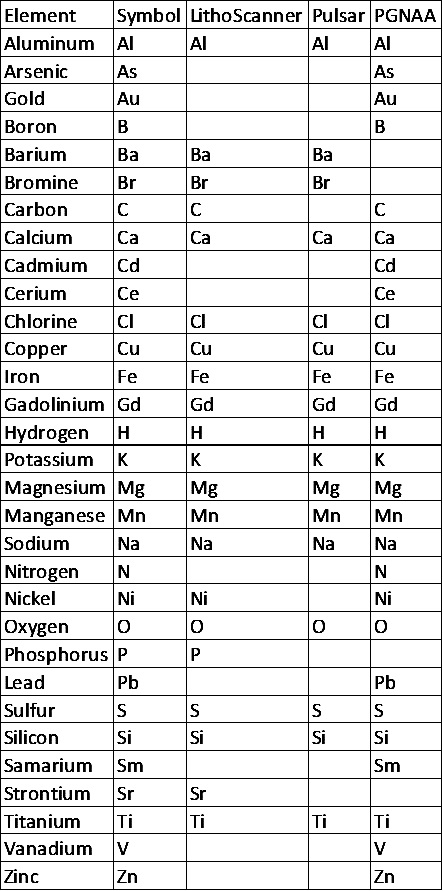

Comparison of elements “seen” by various tools.

High Resolution Temperature Logs

High Resolution Temperature Logs

In the

1980s, the Borehole Geophysics Group of the Geological Survey of

Canada developed a sensor to quantify borehole temperature to a

resolution of 0.001 degree Celsius. (6) Roke Oil

Enterprises in Calgary developed a tool with the same resolution

about the same time and offered the service commercially. The

resolution of most tools is 0.01C.

Temperature gradients can change by formation and results can be

used to map thermal conductivity contrasts, plus detect massive

sulphides. Other applications include predicting proximity to old

mine workings, where the heat dissipates from the warmer underground

openings, finding the base of

permafrost, understanding groundwater flow patterns, and locating

gas flows through “worm-holes” in the cement behind casing.

|