|

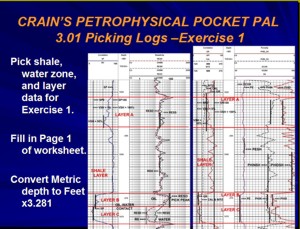

Your complete online Petrophysics Reference Manual

covering Petroleum, Minerals, and other Essential Commodities for

the Energy Transition

Loading Table of Contents...

|

||

|

Page Views ---- Since 01 Jan 2015

Copyright 2024 by Accessible Petrophysics Ltd. CPH Logo, "CPH", "CPH Gold Member", "CPH Platinum Member", "Crain's Rules", "Meta/Log", "Computer-Ready-Math", "Petro/Fusion Scripts" are Trademarks of the Author |

||

|

||

| Site Navigation | CHAPTER and TOPIC INDEX CRAIN'S PETROPHYSICAL HANDBOOK | Quick Links |