|

CORE POROSITY BASICS

CORE POROSITY BASICS

Porosity is an intrinsic property of reservoir

rocks and indicates the storage capacity of the reservoir.

It is used as a primary indicator of reservoir quality, and

along with a few other factors, to calculate

hydrocarbon volume in place, and recoverable reserves. Petrophysicists use core porosity values to help calibrate

porosity derived from well log data.

CORE POROSITY DEFINITIONS

CORE POROSITY DEFINITIONS

Porosity is the volume of the portion of the rock filled

with fluids, divided by the total volume of the rock. It is

usually abbreviated with Greek letter PHI, with subscripts

to indicate the porosity type, eg. PHIt, PHIe, PHIsec.

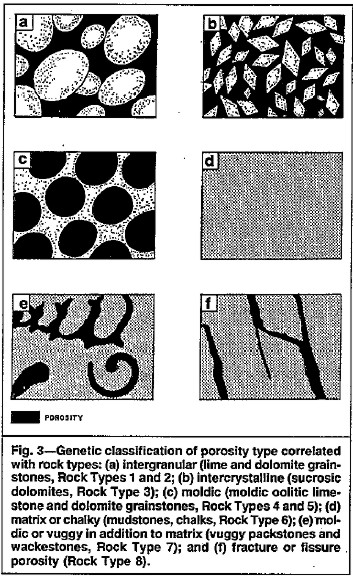

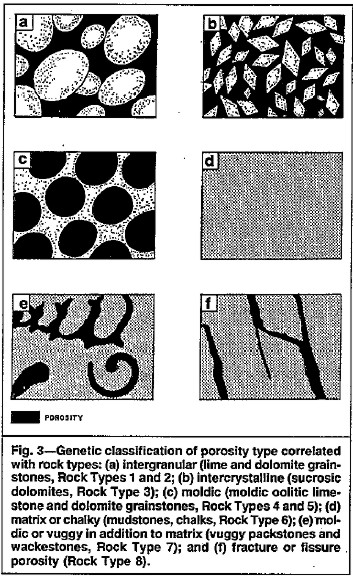

Primary porosity is the porosity developed by the original sedimentation

process by which the rock was created. In reports, it is often

referred to in terms of percentages, while in calculations it

is always a decimal fraction.

Secondary porosity is created by processes other than primary

cementation and compaction of the sediments. An example of secondary

porosity can be found in the solution of limestone or dolomite

by ground waters, a process which creates vugs or caverns. Fracturing

also creates secondary porosity. Dolomitization results in the

shrinking of solid rock volume as the material transforms from

calcite to dolomite, giving a corresponding increase in porosity.

In the laboratory, porosity is usually derived from easily

made measurements such as weight and volume. Here are the

definitions needed:

* Vg = grain volume

* Vp = pore volume

* Vb = bulk volume of a rock = Vg + Vp

* PHIcore = core porosity = Vp / Vb

OR:

* PHIcore = = core porosity = (Vb - Vg) / Vb

Notes:

"V" in this Chapter stands for Volume, not

Velocity.

These volumes are usually reported in cubic

centimeters (cc).

PHIcore may be close to total porosity (PHIt) or effective

porosity (PHIe) or somewhere in-between, depending on the core

analysis method and the details of how that method was applied.

The properties Vb, Vg, and Vp can be measured in the lab on full diameter core or on

smaller core plugs drilled from the whole core, or from sidewall

percussion or sidewall rotary cores. Whole core is best in

heterogeneous reservoirs and in low porosity reservoirs.

MEASURING BULK VOLUME (Vb)

MEASURING BULK VOLUME (Vb)

There are 3 ways to measure bulk volume:

s. direct measurement of the dimensions of a

regular solid

b. fluid displacement using Archimedes Principle

c. fluid displacement using calibrated container

(pycmometer)

DIRECT MEASUREMENT: Bulk Volume = Pi * Length * Radius

squared

DIRECT MEASUREMENT: Bulk Volume = Pi * Length * Radius

squared

4: Vb = PI * L * D^2 / 4

This method is less accurate due to the roughness of the

surfaces of the solid and imperfections in shape.

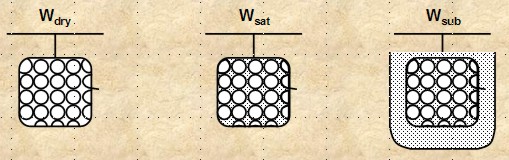

ARCHIMEDES METHOD

ARCHIMEDES METHOD

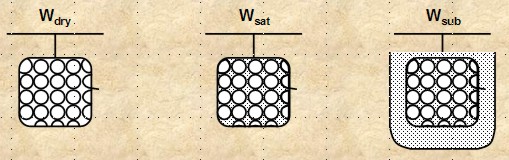

This

technique utilizes the Archimedes’ principle of mass

displacement in a liquid (buoyancy):

a. The core is first cleaned, dried,

and weighed in air (WTdry)

b. The core sample is then saturated

with a wetting fluid and weighed (WTsat)

(the core may be coated with paraffin to prevent evaporation)

c. The sample is then submerged in

the same fluid and its submerged weight is measured (WTsub)

d. The bulk volume is the difference

between the last two weights divided by the density of the fluid.

e. The porosity is the difference

between the first two weights divided by the density of the fluid.

Bulk

Volume = (Weight in air (saturated) - Weight submerged) / Density of Fluid

5: Vb = (WTair - WTsub) / DENSfl

6: Vg = (WTdry - WTsub) / DENSfl

7: Vp = (WTsat - WTdry) / DENSfl

8: PHIt = (WTsat - WTdry) / (WTsat -

WTsub) = Vp / Vb

Bulk Density = Saturated Weight / Bulk Volume

9: BulkDens = WTsat / Vb

If clays are present and sample is maintained at a high humidity

(not over dried), this last equation gives PHIe, not PHIt.

Laboratory measurements using this technique are very accurate.

CALIBRATED DISPLACEMENT METHOD

CALIBRATED DISPLACEMENT METHOD

The bulk volume can be determined also by the volume of the

displaced fluid. Fluids that

are normally used are water,

which can easily be evaporated afterwards, and mercury, which normally does not enter

the pore space in a core sample due to its non-wetting

capability and its large interfacial tension against air.

Bulk

Volume = Volume of Displaced Fluid = Weight Displaced Fluid /

Density Displaced Fluid

10: Vb = WTdisp / DENSfl

Laboratory measurements using this technique are very accurate.

NUMERICAL

EXAMPLE:

NUMERICAL

EXAMPLE:

WTdry = dry weight in air = 16.0 gm

WTsat = weight of saturated sample in air = 20.0 gm

WTcoated = weight of dry sample coated with paraffin = 20.9 gm

(density of paraffin = 0.9 gm/cc)

WTsub = weight coated sample immersed in water at 70 °F = 10 gm

(density of water = 1.0 gm/cc)

Determine bulk volume

Weight of paraffin = WTcoated - WTsar = 20.9 -

20.0 = 0.9 gm

Density of Parrafin = 0.9 gm/cc

Volume of paraffin = WTpar / DENSpar = 0.9 / 0.9 = 1.0 cc

Weight of water displaced = WTcoated - Wtsub = 20.9 - 10.0 =

10.9 gm

Volume of water displaced = 10.9 / 1.0 = 10.9 cc

Volume of water minus displaced-volume of

paraffin = 10.9 - 1.0 = 9.9 cc

Bulk volume of rock = 9.9 cc

MEASURING GRAIN VOLUME (Vg) MEASURING GRAIN VOLUME (Vg)

There are 3 ways to measure grain

density in the lab:

a. assume a grain density, compare to

dry weight

b. displaced fluid method

c. Boyle's Law

ASSUMED GRAIN DENSITY

ASSUMED GRAIN DENSITY

Determine Vg from the dry weight of the sample and the

rock grain density (2.65 gm/cc for quartz grains). This method

is not very accurate if grain density varies due to varying

mineralogy.

Grain Volume =

Dry Sample Weight / Grain Density

11: Vg = WTdry / DENSMA

DISPLACED FLUID METHOD

DISPLACED FLUID METHOD

A more accurate approach is to use the displaced fluid

volume. First the core plug is measured to obtain its bulk

volume, as described earlier Then the sample is crushed to eliminate all porosity and

weighed (WTgr). A glass tube filled with water, called a pycnometer to

confuse novices, is weighed (W1), then the crushed rock is placed in

the tube (still filled with water), and weighed again WT2). The

difference in weights gives the volume of displaced fluid.

Displaced

Volume = Crushed Sample Weight + Water-filled tube Weight

- Combined Weight

12: Vdisp = (WT2 - WT1)

Grain Volume = Displaced Volume /

Water Density

13: Vg = Vdisp / DENSwater

Porosity = (Bulk Volume - Grain

Volume) / Bulk Volume

14: PHIt = (Vb - Vg) ' Vb

If clays are present and sample is maintained at a high

humidity (not over dried), this last equation gives PHIe, not

PHIt.

Grain Density = Dry Weight in Air / Grain Volume

15: GrainDens = WTdry / Vg

NUMERICAL

EXAMPLE:

NUMERICAL

EXAMPLE:

WTdry = Weight of dry crushed sample in air = 16.0 gm,

WT1 = Weight of pycnometer filled with water at 70 °F =

65.0 gm

WT2 = Weight of pycnometer filled with water and crushed sample

= 75.0 gm

Calculate grain volume

Volume of water displaced = 16.0 + 65.0 - 75.0 = 6.0 gm

Grain Volume = 6.0 / 1.0 = 6.0 cc

Calculate porosity

Bulk volume of the sample = 9.9 cc, from previous example

Total porosity = (9.9 - 6.0) / 9.9 = 0.394 fractional

porosity (39.4%)

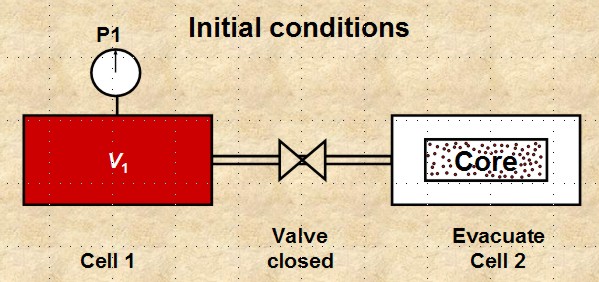

BOYLE'S LAW METHOD

BOYLE'S LAW METHOD

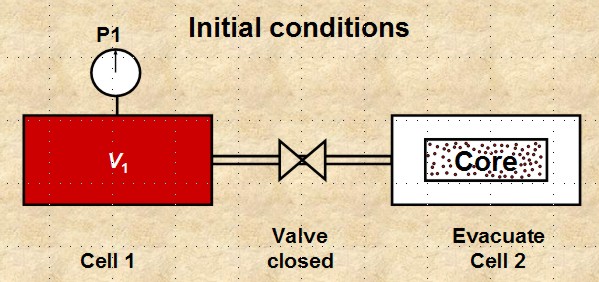

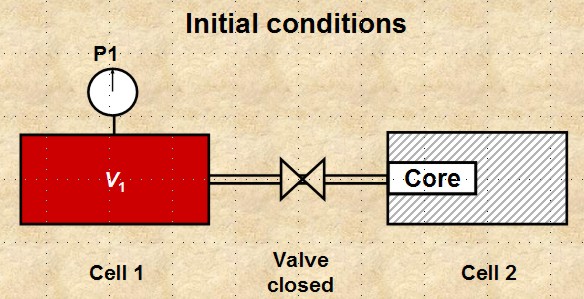

An

alternate grain volume method makes use of Boyle’s Law.

This gas

transfer technique involves the injection and decompression of

gas (Helium, CO2, or N2) into the pores of a fluid-free

(vacuum), dry core sample. Either the pore volume or the grain

volume can be determined, depending upon the instrumentation and

procedures.

To determine grain volume using ideal gas law at constant

temperature:

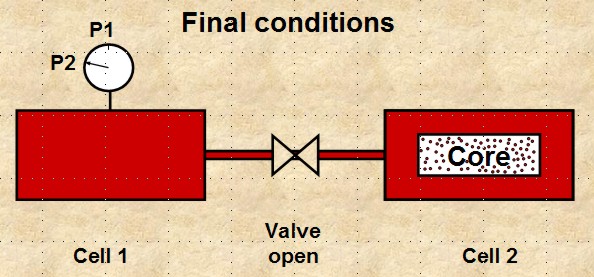

a. connect two cells of known volume, Vcell1 and Vcell2

b. close valve between cells, apply pressure P1 to cell 1

c. place dry core sample in cell 2, seal and evacuate cell 2

d. open valve and measure pressure P2

Boyle's Law apparatus to measure grain volume Vg

16: V2

= P1 * Vcell1 / P2

Since V2 = Vcell1 + Vcell2 - Vg And Vtotal = Vcell1 + Vcell2

Then 17: Vg = Vt - Vf

MEASURING PORE VOLUME MEASURING PORE VOLUME

In previous sections pore volume Vp

was derived from volumetric methods based on weight and density.

Semi-direct measurement of porosity can also be attempted.

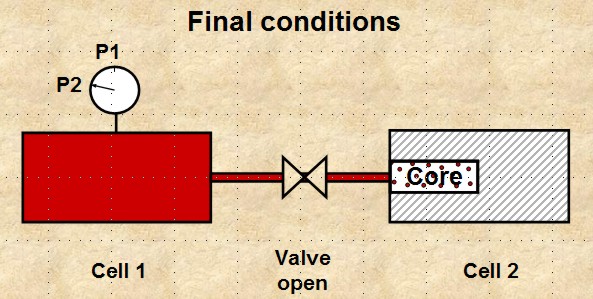

BOYLE'S LAW METHOD

BOYLE'S LAW METHOD

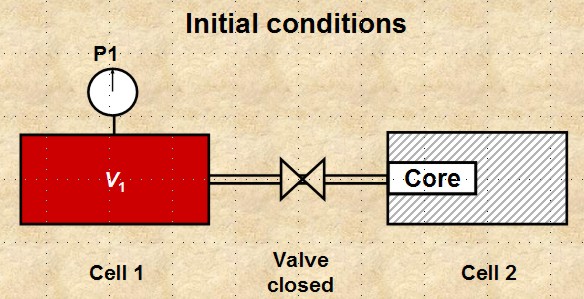

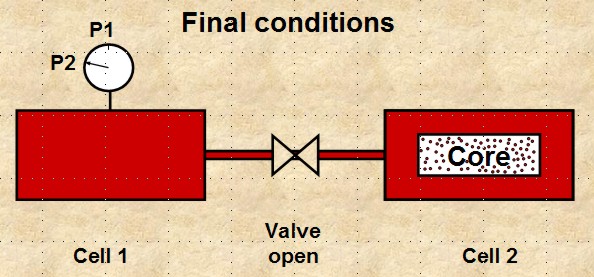

Pore volume measurements can be done by using the Boyle’s Law

model, where the sample is placed in a rubber sleeve holder that

has no void space around the periphery of the core and on the

ends. Such a holder is called the Hassler holder, or a

hydrostatic load cell. Helium

or one of its substitutes is injected into the core plug through

the end stem.

Boyle's Law apparatus for determining porosity

18: V2

= P1 * Vcell1 / P2

Since V2 = Vcell1 + PHIe

Then 19: Vp = V2 - Vcell1

FLUID SUMMATIONS METHOD

FLUID SUMMATIONS METHOD

This technique is used to measure the volume of gas, oil and

water present in the pore space of a fresh or preserved

(peel-sealed) core of known bulk volume. The volumes of the

extracted oil, gas, and water are added to obtain the pore

volume and hence the core porosity.

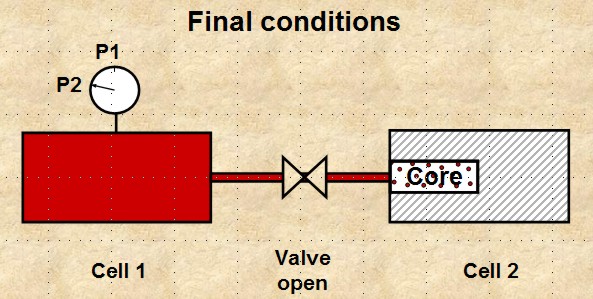

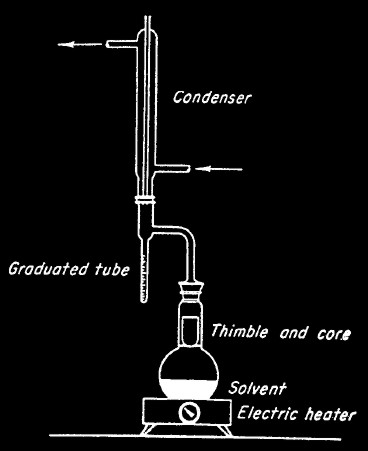

DEAN-STARK CORE ANALYSIS METHOD

DEAN-STARK CORE ANALYSIS METHOD

This method is used in poorly consolidated rocks such as

tar samds and involves

disaggregating the samples and weighing their constituent

components. Samples are usually frozen or wrapped in plastic to

preserve the contents during transport. In the lab, the still

frozen cores are slabbed for photography and description, then

samples are selected and weighed.

Samples are then heated and crumbled to drive off water, and

weighed again. The weight loss gives the water weight. Solvents

are used to remove oil or tar. The sample is weighed again and

the weight loss is the weight of oil. The matrix rock is

separated into clay and mineral components by flotation, dried

and weighed again, giving the weight of clay and weight of the

mineral grains.

20: WTwtr = WTsample - WTheated

21: WTtar = WTheated - WTminerals&clay

By dividing each weight by its respective density and

adjusting each result for the total weight of the sample, the

volume fraction of each is obtained. Porosity is the sum of

water plus oil volume fractions Because the bound water in

the clay is driven off by the drying sequences, this porosity is

the total porosity. By dividing each weight by its respective density and

adjusting each result for the total weight of the sample, the

volume fraction of each is obtained. Porosity is the sum of

water plus oil volume fractions Because the bound water in

the clay is driven off by the drying sequences, this porosity is

the total porosity.

22: VOLwtr = WTwtr / DENSwtr / WTsample

23: VOLtar = WTtar / DENStar / WTsample

24: PHIcore = VOLwtr + VOLtar

Dean-Stark laboratory apparatus Dean-Stark laboratory apparatus

Assuming clay bound water is driven off by heating and drying,

then PHIcore equals total porosity. From comparison to log

analysis results, it appears that some clay bound water remains

in many cases, so PHIcore lies between total and effective

porosity from log analysis. Assuming clay bound water is driven off by heating and drying,

then PHIcore equals total porosity. From comparison to log

analysis results, it appears that some clay bound water remains

in many cases, so PHIcore lies between total and effective

porosity from log analysis.

Example of Dean-Stark porosity (dots) showing that it is

less than total porosity

from logs (black curve) due to incomplete drying of clay. Trying to match

log

porosity directly to core may be futile in many cases. Scale is 0.50 to

0.00.

OIL MASS FROM CORE LISTINGS

OIL MASS FROM CORE LISTINGS

If not provided on the core listing, the equivalent value of tar mass from core analysis

is derived from porosity, oil saturation, and an assumed oil

density:

25: Wtar = PHIcore * Star * DENStar

26: Wwtr = PHIcore * Swtr * DENSwtr

27: Wrock = (1 – PHIcore) * GR_DENScore

Where:

Star = tar volume relative to pore volume

Swtr = water volume relative to pore volume

PHIcore = volume of water + valume of tar

Wtar = tar mass fraction

Wwtr = water mass fraction

Wrockcore = rock mass fraction

|

PHIcore |

Soil |

Swtr |

Vol Tar |

Vol Wtr |

GR_ DEN |

WT Oil |

WT Sand |

WT Wtr |

WT Rock |

Oil Mass Wtar |

Wtr Mass Wwtr |

Rock Mass Wrock |

|

frac |

frac |

frac |

frac |

frac |

kg/m3 |

|

|

|

|

frac |

frac |

frac |

|

0.306 |

0.301 |

0.699 |

0.092 |

0.214 |

2.650 |

0.092 |

1.839 |

0.212 |

2.143 |

0.043 |

0.099 |

0.858 |

|

0.271 |

0.236 |

0.764 |

0.064 |

0.207 |

2.650 |

0.064 |

1.932 |

0.207 |

2.203 |

0.029 |

0.094 |

0.877 |

|

0.279 |

0.306 |

0.694 |

0.085 |

0.194 |

2.650 |

0.085 |

1.911 |

0.193 |

2.189 |

0.039 |

0.088 |

0.873 |

|

0.244 |

0.304 |

0.696 |

0.074 |

0.170 |

2.650 |

0.074 |

2.003 |

0.168 |

2.246 |

0.033 |

0.075 |

0.892 |

|

0.298 |

0.217 |

0.783 |

0.065 |

0.233 |

2.650 |

0.065 |

1.860 |

0.233 |

2.158 |

0.030 |

0.108 |

0.862 |

|

0.273 |

0.298 |

0.702 |

0.081 |

0.192 |

2.650 |

0.081 |

1.927 |

0.191 |

2.199 |

0.037 |

0.087 |

0.876 |

If saturations (or pore volume) are

known, as well as core porosity, all other terms can be calculated.

Some core analysis reports do the math for you, some do not.

Since GR_DENScore represents a mixture of quartz and

shale, this value should vary with shale volume. However shale

volume is never reported on core analysis, so the composite grain

density from the rock sample is used. If grain density is

not recorded in the core analysis, we must assume a constant of 2650 kg/m3 or lower.

FLUID VOLUMES FROM CORE LISTINGS

FLUID VOLUMES FROM CORE LISTINGS

If not provided on the core listing, the equivalent value of tar

volumes from core analysis

are derived from porosity, tar mass fraction, and an assumed oil

density:

27: Star = Wtar / (PHIcore * DENStar)

28: Swtr

= Wwtr / (PHIcore * DENSwtr)

OR 29: Swtr = 1.00 - Star

Where:

Star = tar volume relative to pore volume

Swtr = water volume relative to pore volume

PHIcore = volume of water + valume of tar

Wtar = tar mass fraction

Wwtr = water mass fraction

|

PHIcore |

Star |

Swtr |

Vol Oil |

Vol Wtr |

GR_ DEN |

WT Tar |

WT Sand |

WT Wtr |

WT Rock |

Tar Mass Wtar |

Wtr Mass Wwtr |

Rock Mass Wrock |

|

frac |

frac |

frac |

frac |

frac |

kg/m3 |

|

|

|

|

frac |

frac |

frac |

|

0.306 |

0.301 |

0.699 |

0.092 |

0.214 |

2.650 |

0.092 |

1.839 |

0.212 |

2.143 |

0.043 |

0.099 |

0.858 |

|

0.271 |

0.236 |

0.764 |

0.064 |

0.207 |

2.650 |

0.064 |

1.932 |

0.207 |

2.203 |

0.029 |

0.094 |

0.877 |

|

0.279 |

0.306 |

0.694 |

0.085 |

0.194 |

2.650 |

0.085 |

1.911 |

0.193 |

2.189 |

0.039 |

0.088 |

0.873 |

|

0.244 |

0.304 |

0.696 |

0.074 |

0.170 |

2.650 |

0.074 |

2.003 |

0.168 |

2.246 |

0.033 |

0.075 |

0.892 |

|

0.298 |

0.217 |

0.783 |

0.065 |

0.233 |

2.650 |

0.065 |

1.860 |

0.233 |

2.158 |

0.030 |

0.108 |

0.862 |

|

0.273 |

0.298 |

0.702 |

0.081 |

0.192 |

2.650 |

0.081 |

1.927 |

0.191 |

2.199 |

0.037 |

0.087 |

0.876 |

If oil mass fraction and water mass

fraction are known, as well as core porosity, all other terms can be

calculated. Some core analysis reports do the math for you, some do

not.

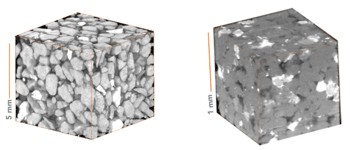

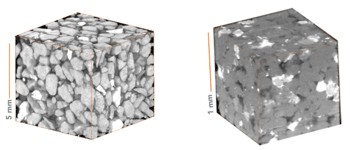

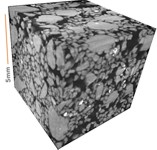

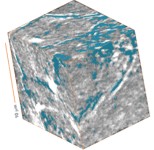

POROSITY FROM

MICRO CT SCANS

POROSITY FROM

MICRO CT SCANS

Porosity is directly calculated from

high resolution digital images such

as those shown below. This

calculation is the ratio of the

number of voxels that fall into the

pore space (black and dark-gray) to

the total number of voxels in a 3D

image. The task of separating the

pores from grains in such 3D objects

is called image segmentation.

The main technical challenge in

image segmentation is the gradual

transition from dark to light shade

of gray at the edges of the pore

space. Proprietary image-processing

algorithms are used, which

include statistical analysis of the

gray-scale images. As a result, the

pore space is accurately separated

from the mineral matrix and the

porosity is computed. Source:

www.ingrainrocks.com.

Clean sand 39%

Tight sand 5%

Poorly sorted 12%

Silty Shale 8%

Black = Porosity, Grey =

Matrix Grains, White = Heavy

Minerals

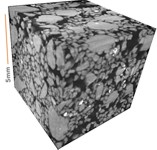

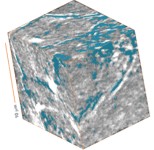

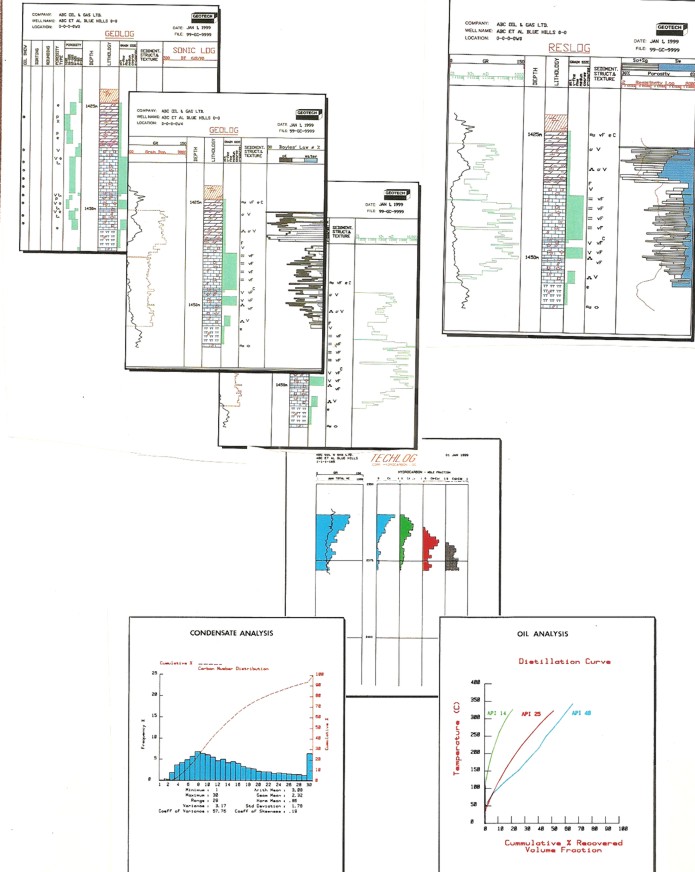

SAMPLE CORE ANALYSIS REPORT SAMPLE CORE ANALYSIS REPORT

Samples of core analysis and core description plots, with a few

of the posible histograms and crossplots that can be made.

|

02181815W4 |

#23708 |

731011 |

|

NOTE: Accumap has Kvert in K90 Column |

|

S# |

Top |

Base |

Len |

Kmax |

K90 |

Kvert |

Poros |

GrDen |

BkDen |

Soil |

Swtr |

Lithology |

|

|

feet |

feet |

feet |

mD |

mD |

mD |

Frac |

kg/m3 |

kg/m3 |

frac |

frac |

|

|

1 |

3499.19 |

3500.17 |

0.98 |

742.0 |

0.0 |

180.0 |

0.283 |

0 |

0 |

0.129 |

0.448 |

SS VF-F |

|

2 |

3500.17 |

3501.16 |

0.98 |

1196.0 |

0.0 |

694.0 |

0.297 |

0 |

0 |

0.123 |

0.450 |

SS VF-F |

|

3 |

3501.16 |

3502.17 |

1.02 |

622.0 |

0.0 |

266.0 |

0.276 |

0 |

0 |

0.111 |

0.520 |

SS VF-F |

|

4 |

3502.17 |

3503.16 |

0.98 |

223.0 |

0.0 |

50.5 |

0.271 |

0 |

0 |

0.129 |

0.479 |

SS VF-F |

|

5 |

3503.16 |

3503.88 |

0.72 |

837.0 |

0.0 |

171.0 |

0.278 |

0 |

0 |

0.110 |

0.504 |

SS VF-F PY |

|

6 |

3503.88 |

3504.57 |

0.69 |

407.0 |

0.0 |

113.0 |

0.287 |

0 |

0 |

0.118 |

0.466 |

SS VF-F |

|

7 |

3504.57 |

3504.67 |

0.10 |

|

0.0 |

0.0 |

0 |

0 |

0 |

0 |

0 |

SH |

|

8 |

3504.67 |

3505.26 |

0.59 |

514.0 |

0.0 |

365.0 |

0.253 |

0 |

0 |

0.151 |

0.398 |

|

|

9 |

3505.26 |

3505.49 |

0.23 |

100.0 |

0.0 |

2.6 |

0.201 |

0 |

0 |

0.134 |

0.358 |

SS VF-F SH INC |

|

10 |

3505.49 |

3505.98 |

0.49 |

401.0 |

0.0 |

120.0 |

0.254 |

0 |

0 |

0.143 |

0.268 |

SS VF-F SHBKS |

|

11 |

3505.98 |

3506.96 |

0.98 |

478.0 |

0.0 |

302.0 |

0.282 |

0 |

0 |

0.131 |

0.471 |

SS VF-F |

|

12 |

3506.96 |

3507.88 |

0.92 |

431.0 |

0.0 |

100.0 |

0.243 |

0 |

0 |

0.156 |

0.399 |

SS VF-F CARB INC |

|

13 |

3507.88 |

3508.47 |

0.59 |

777.0 |

0.0 |

556.0 |

0.277 |

0 |

0 |

0.119 |

0.389 |

SS VF-F |

|

14 |

3508.47 |

3508.87 |

0.39 |

831.0 |

0.0 |

383.0 |

0.275 |

0 |

0 |

0.136 |

0.422 |

SS VF-F CARB BK |

|

15 |

3508.87 |

3509.88 |

1.02 |

413.0 |

0.0 |

262.0 |

0.281 |

0 |

0 |

0.132 |

0.440 |

SS VF-F |

|

16 |

3509.88 |

3510.87 |

0.98 |

604.0 |

0.0 |

425.0 |

0.277 |

0 |

0 |

0.131 |

0.323 |

SS VF-F SH INC |

|

17 |

3510.87 |

3511.88 |

1.02 |

320.0 |

0.0 |

35.1 |

0.229 |

0 |

0 |

0.146 |

0.422 |

SS VF-F SH INC |

|

18 |

3511.88 |

3512.87 |

0.98 |

616.0 |

0.0 |

437.0 |

0.239 |

0 |

0 |

0.103 |

0.354 |

SS VF-F |

|

19 |

3512.87 |

3513.79 |

0.92 |

259.0 |

0.0 |

62.0 |

0.261 |

0 |

0 |

0.073 |

0.418 |

SS VF-F |

|

20 |

3513.79 |

3514.38 |

0.59 |

320.0 |

0.0 |

26.8 |

0.219 |

0 |

0 |

0.096 |

0.441 |

|

|

21 |

3514.38 |

3515.07 |

0.69 |

431.0 |

0.0 |

82.5 |

0.236 |

0 |

0 |

0.119 |

0.387 |

SS VF-F |

|

22 |

3515.07 |

3515.16 |

0.10 |

|

0.0 |

0.0 |

|

|

|

|

|

SH PY |

|

23 |

3515.16 |

3516.18 |

1.02 |

969.0 |

0.0 |

628.0 |

0.270 |

0 |

0 |

0.044 |

0.492 |

SS VF-F |

|

24 |

3516.18 |

3516.77 |

0.59 |

837.0 |

0.0 |

634.0 |

0.280 |

0 |

0 |

0.042 |

0.501 |

SS VF-F |

|

25 |

3516.77 |

3517.46 |

0.69 |

556.0 |

0.0 |

201.0 |

0.273 |

0 |

0 |

0.050 |

0.531 |

SS VF-F CARB INC |

|

26 |

3517.46 |

3518.28 |

0.82 |

706.0 |

0.0 |

338.0 |

0.262 |

0 |

0 |

0.046 |

0.487 |

SS VF-F |

|

27 |

3518.28 |

3519.07 |

0.79 |

502.0 |

0.0 |

377.0 |

0.238 |

0 |

0 |

0.079 |

0.494 |

SS VF-F CARB INC |

|

28 |

3519.07 |

3519.99 |

0.92 |

1136.0 |

0.0 |

183.0 |

0.263 |

0 |

0 |

0.063 |

0.501 |

SS VF-F |

|

29 |

3519.99 |

3520.58 |

0.59 |

825.0 |

0.0 |

291.0 |

0.265 |

0 |

0 |

0.052 |

0.563 |

|

|

30 |

3520.58 |

3521.46 |

0.89 |

1346.0 |

0.0 |

706.0 |

0.274 |

0 |

0 |

0.055 |

0.516 |

SS VF-F |

|

31 |

3521.46 |

3522.48 |

1.02 |

389.0 |

0.0 |

102.0 |

0.246 |

0 |

0 |

0.064 |

0.450 |

SS VF-F/M CARB INC |

|

32 |

3522.48 |

3523.47 |

0.98 |

165.0 |

0.0 |

11.9 |

0.219 |

0 |

0 |

0.058 |

0.408 |

SS VF-F/M CARB INC |

|

33 |

3523.47 |

3524.48 |

1.02 |

586.0 |

0.0 |

66.0 |

0.219 |

0 |

0 |

0.082 |

0.411 |

|

|

34 |

3524.48 |

3525.47 |

0.98 |

1035.0 |

0.0 |

395.0 |

0.244 |

0 |

0 |

0.051 |

0.391 |

SS VF-F |

|

35 |

3525.47 |

3526.48 |

1.02 |

514.0 |

0.0 |

187.0 |

0.199 |

0 |

0 |

0.073 |

0.360 |

|

|

36 |

3526.48 |

3527.47 |

0.98 |

526.0 |

0.0 |

89.0 |

0.205 |

0 |

0 |

0.046 |

0.481 |

SS VF-M |

|

37 |

3527.47 |

3528.16 |

0.69 |

1375.0 |

0.0 |

208.0 |

0.216 |

0 |

0 |

0.042 |

0.548 |

SS VF-M PY CARB |

|

38 |

3528.16 |

3528.88 |

0.72 |

287.0 |

0.0 |

95.0 |

0.207 |

0 |

0 |

0.066 |

0.462 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Arithmetic Averages |

0.78 |

618.8 |

0.0 |

240.7 |

0.253 |

0.0 |

0.0 |

0.095 |

0.443 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

By dividing each weight by its respective density and

adjusting each result for the total weight of the sample, the

volume fraction of each is obtained. Porosity is the sum of

water plus oil volume fractions Because the bound water in

the clay is driven off by the drying sequences, this porosity is

the total porosity.

By dividing each weight by its respective density and

adjusting each result for the total weight of the sample, the

volume fraction of each is obtained. Porosity is the sum of

water plus oil volume fractions Because the bound water in

the clay is driven off by the drying sequences, this porosity is

the total porosity. Assuming clay bound water is driven off by heating and drying,

then PHIcore equals total porosity. From comparison to log

analysis results, it appears that some clay bound water remains

in many cases, so PHIcore lies between total and effective

porosity from log analysis.

Assuming clay bound water is driven off by heating and drying,

then PHIcore equals total porosity. From comparison to log

analysis results, it appears that some clay bound water remains

in many cases, so PHIcore lies between total and effective

porosity from log analysis.