|

HYDROGEN BASICS

HYDROGEN BASICS

Hydrogen is the smallest and lightest element. At standard

conditions hydrogen is a diatomic gas (H2). It is

colorless, odourless, tasteless, non-toxic, and highly combustible,

creating water (H2O) when burned. Hydrogen can be

separated from water by electrolysis and from methane by pyrolysis

or steam reforming.

There is one known example, in Mali, of naturally occurring hydrogen

in a geologic setting, It is a small accumulation but is

revolutionizing geological thought on possible sources of natural

hydrogen. Dozens of hydrogen seeps are known around the World – some

of these may prove to be more than just curiosities.

Most of the hydrogen on Earth exists in water and organic compounds,

and in hydrides inside the Earth.

Known occurrences of natural hydrogen are rare, partly because we

haven’t looked very carefully, due to preconceived opinions that are

now known to be incorrect.

Major uses of hydrogen are making ammonia, upgrading bitumen and

heavy oil, and removal of sulphur from liquid petroleum,

industrial and agricultural chemicals, as well as food

processing.

A new era of hydrogen powered aircraft, railway locomotives, ships,

and ground transport is being led by

innovative entrepreneurs and both large and small business ventures.

So far, very tiny steps forward on a very, very long road to the

“Hydrogen Economy” – think year 2050 or beyond. The virtue of such a

fuel is that the exhaust is water (and maybe some NOx), instead of

CO2, which contributes to climate change. There

are many unresolved technical and practical issues, not the least of

which is what to do with all that water in cold weather. Hydrogen

has the potential to assist the global race for decarbonization.

Stay tuned!

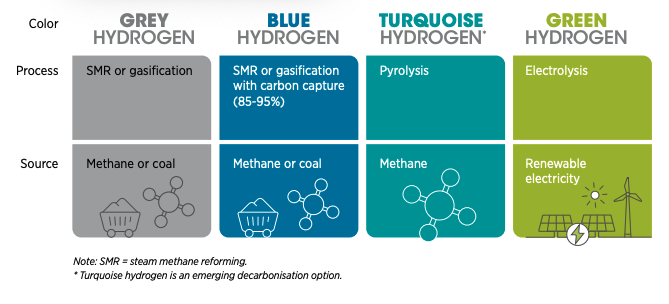

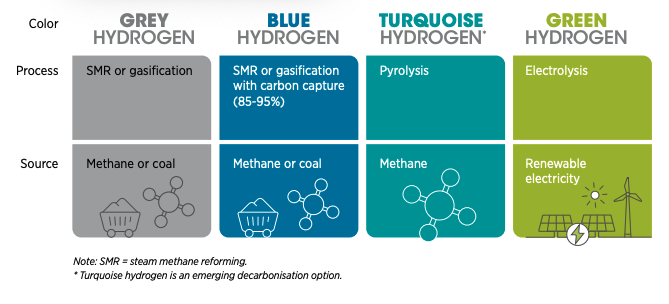

The Colours of Hydrogen: green if produced from 100% renewables;

black, brown, or grey if coal or methane is used; blue if CCS is

added, gold or white if source is naturally occurring. (Image from

World Economic Forum, from 2022 talk by Emanuele Taibi)

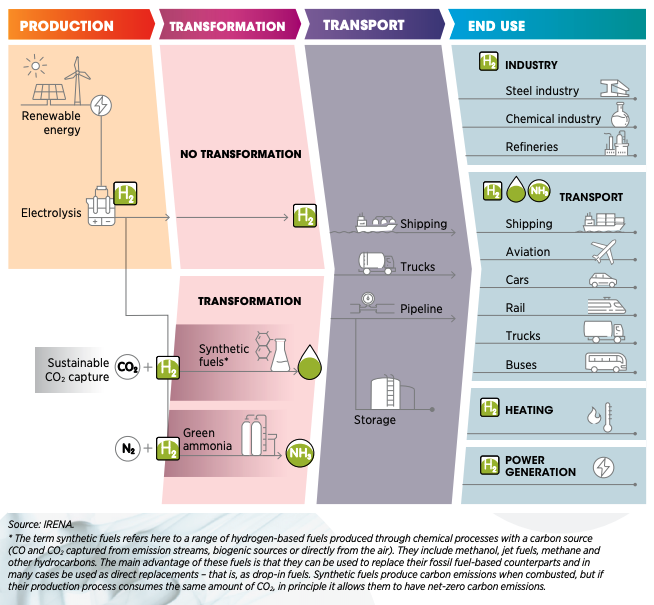

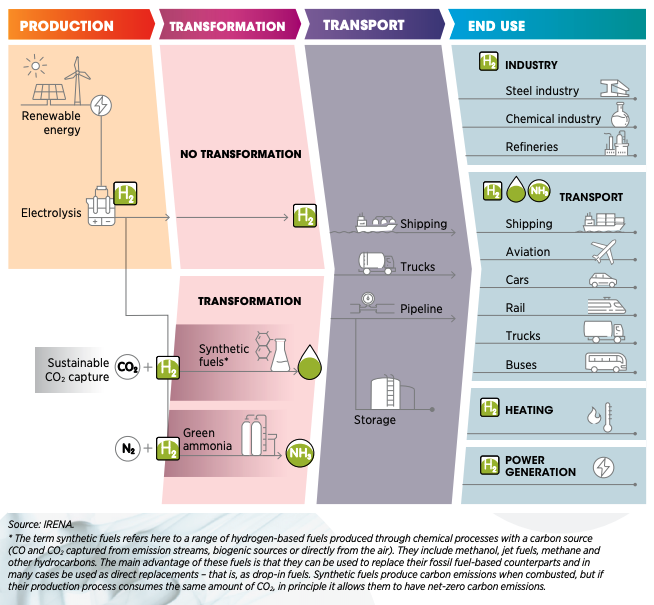

The Green Hydrogen Transition (Image courtesy International

Renewable Energy Agency)

To produce enough Green Hydrogen to displace fossil fuels, we need

to increase renewable electrical energy output by a factor of 1000,

probably much more. And drill and complete unknown thousands of deep

water wells, plus build a desalinization plant for each electrolysis

plant. Why? Because most of the fresh water needed for electrolysis

is already allocated for human and agricultural use.

It might be better to electrify transport and use heat pumps for

HVAC and avoid the H2 middleman. This leaves about

40% of current carbon emissions to be fixed – the carbon-heavy

industrial heartland to decarbonize with Green Hydrogen. As hydrogen

technology improves, the timing might just work out for all those

year 2050 targets that governments have made.

Petrophysical analysis in Hydrogen bearing rocks

Petrophysical analysis in Hydrogen bearing rocks

Petrophysical

analysis in a hydrogen accumulation is truly difficult,

unconventional, and still open to improvement.

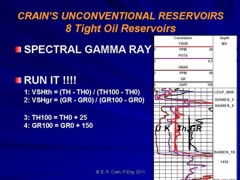

Natural hydrogen gas accumulations do not behave on well logs in the

same way as methane gas reservoirs. Hydrogen gas does not exhibit

high resistivity like a methane gas zone. This phenomenon is not

fully understood but may be related to ionization of H2 in the water

in the rock.

When a hydrogen atom dissolves in aqueous solution, it ionizes into

H+ (a proton) and H- (an electron). Protons cannot live in isolation

and immediately hook up to a water molecule, creating the ion H3O+,

called hydronium. As the protons are used up, more hydrogen can be

dissolved and more hydronium is created. H3O+ ions are conductive,

similar to other Group 1 elements, such as sodium (Na+) and

potassium (K+). As a result, conventional water saturation

equations make hydrogen zones look like water zones.

The electrons released during ionization form a telluric

currennt, visible as large negative excursions on the SP

log.

Hydrogen does not produce density neutron crossover (gas effect).

Instead, H2 shows up as if the zone were shale or heavy minerals –

high neutron porosity from higher hydrogen index (HI) with slightly

high density porosity, giving density neutron separation instead of

crossover. The gamma ray can usually distinguish if it is shale or

non-shale rock.

When methane co-exists with hydrogen, open hole logs behave more

like they would in conventional gas zones.

H2 UPDATE JULY 2023

The neutron log responds to all hydrogen in the rock:

1. water in the effective porosity of the reservoir rock,

2. water bound to clay, shale, or gypsum in the reservoir rock,

3. hydrogen diffused into the rock matrix,

4. hydrogen adsorbed onto the various rock surfaces,

5. hydrogen bound chemically to form hydrides

6. hydrogen dissolved in the water as hydronium ions H3O+,

7. and (maybe) hydrogen in the form of free gas in the effective

porosity.

Items 1 and 2 represent the state of a reservoir before any H2 is

formed or migrates into the reservoir.

Items 3 through 6 must saturate their host to the full extent

possible, limited by the temperature and pressure, and

characteristics of each of the physical or chemical processes.

Only then can free H2 gas survive as an accumulation underground.

When producing from a natural or storage reservoir, hydrogen that

diffused or formed hydrides is permanently lost. Some adsorbed gas

and some free gas will be available for production as the reservoir

pressure is reduced. Some natural H2 plays may offer only adsorbed

gas with no free gas in the porosity.

Detailed sample descriptions are critical in determining the actual

mineralogy, since standard 2- and 3-mineral models are unlikely to

behave well in an H2 zone. Multi-mineral models might work, but the

petrophysical properties of H3O+ are as yet unknown.

Hydrogen can

be seen on the mud log C1 gas curve and as a temperature log anomaly

which shows the hydrogen accumulation as a gas cooling effect

compared to geothermal trends.

Fracture intensity, formation dip, and depositional environment can

be determined from resistivity image logs.

Reservoir seal integrity is critical due to the small size of the H2

molecule, which can leak through almost any trap that would contain

CH4, CO2, N2, or He. The best possible seals are lava flows and

evaporites. You still need a stratigraphic or structural trap,

otherwise the H2 will “just keep on a-movin’ ”.

New and

evolving technology may help. One possibility is the fast neutron

cross section measurement (FNSX). Low density CH4 and CO2 have very

low FNXS values, as well as low SIGMA values, compared to water,

heavier hydrocarbons, and rock minerals. A direct calculation of gas

saturation is be possible in these cases. The FNXS and SIGMA values

for H2 and H3O+ in an accumulation setting are currently unknown, so

we will wait and see what develops.

Elemental yields from a slim hole induced gamma ray spectroscopy log

(eg Schlumberger Pulsar log) might resolve the presence of hydrogen

or hydronium-ions. It should be possible to tune the element to

mineral transform to include H2 and H3O+ in the allowed “mineral”

list.

It has also been observed in ROKE Quad Neutron logging that the

borehole resistivity measurement correlates with the Mudlog H2

signal. One pass with this slim hole logging tool is all that is

needed to identify a hydrogen gas accumulation.

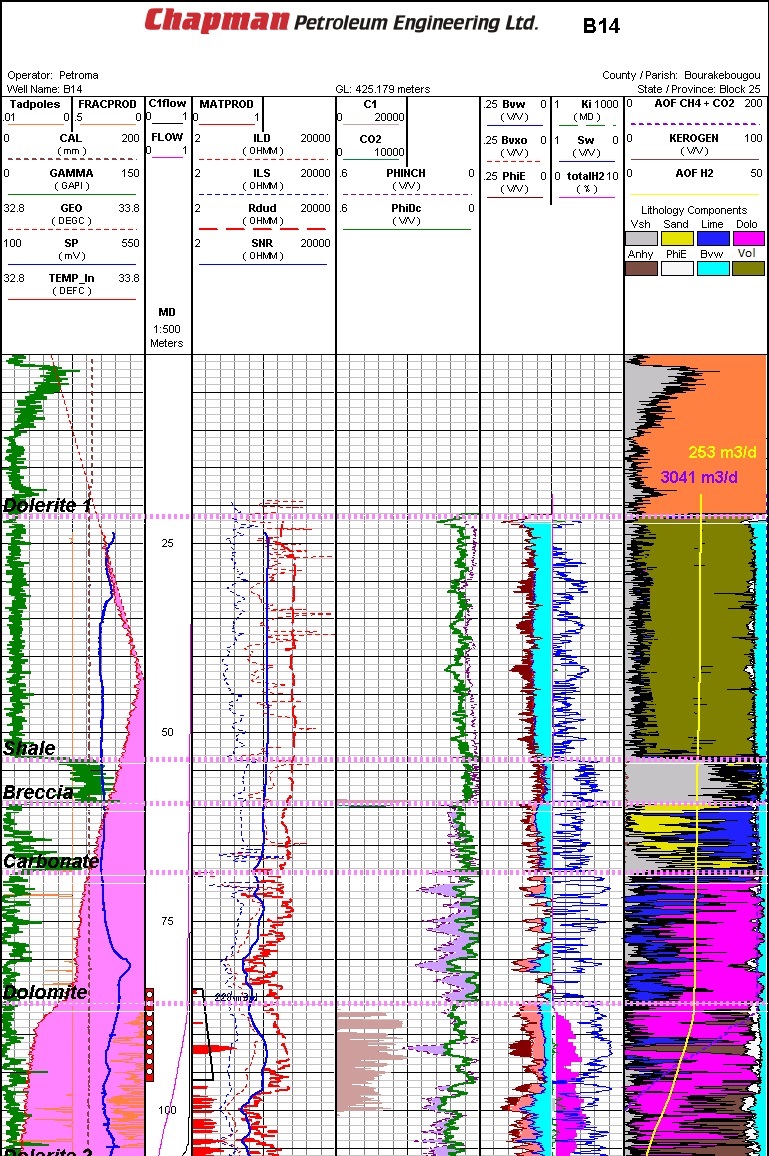

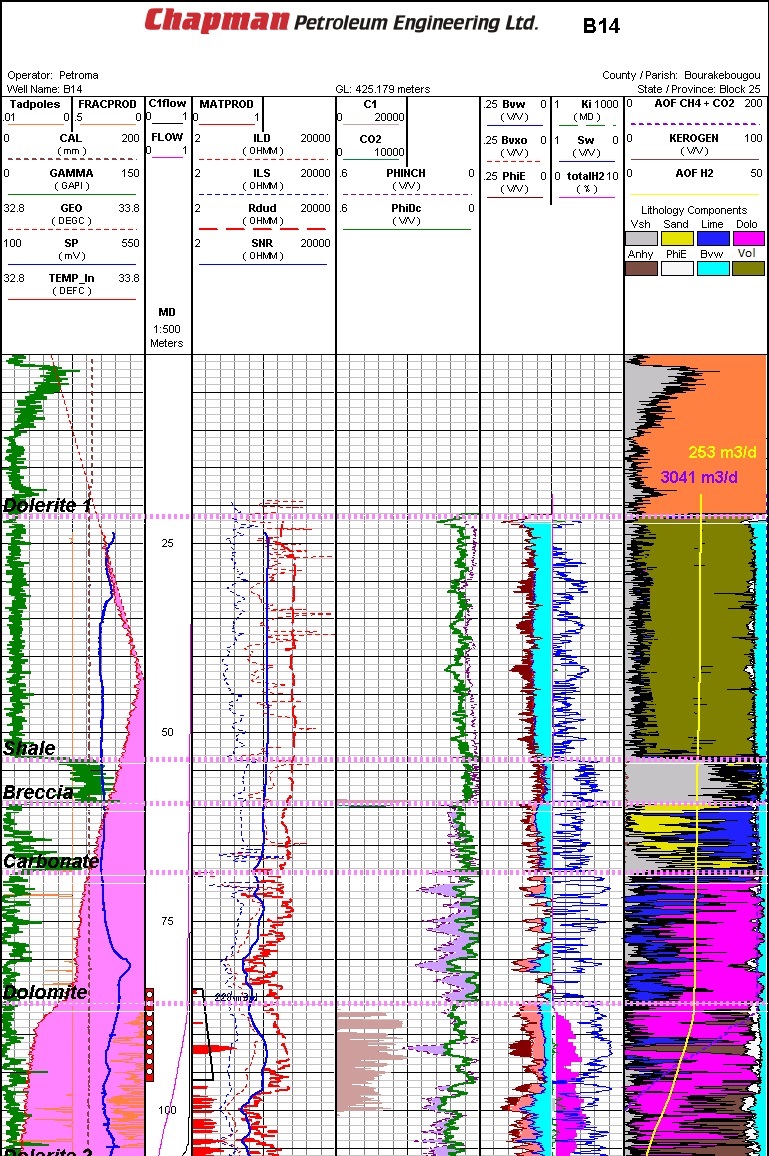

NATURAL HYDROGEN EXAMPLE --

MALI

NATURAL HYDROGEN EXAMPLE --

MALI

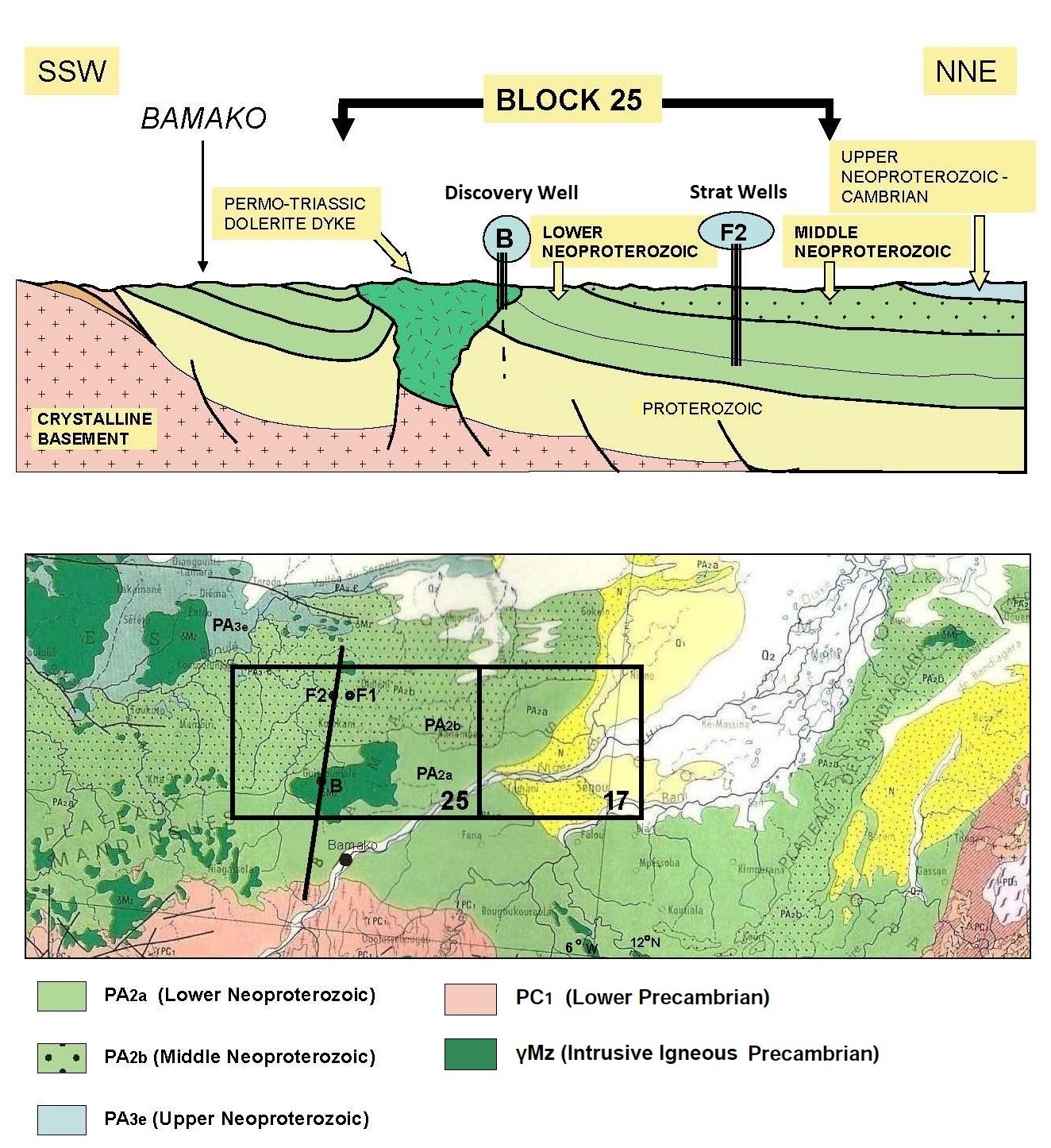

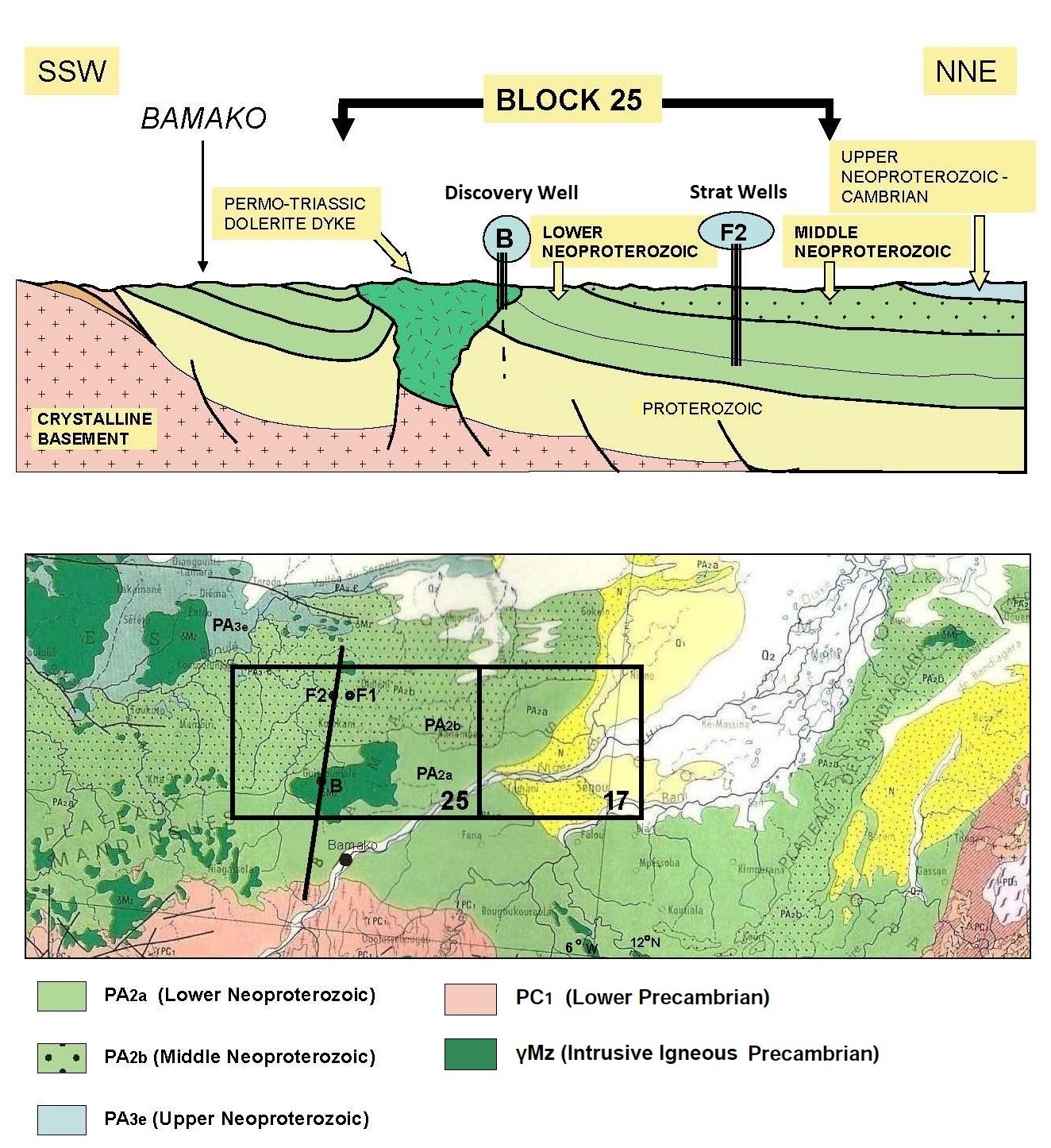

Conventional literature says that hydrogen gas does not occur

naturally in convenient accumulations like oil and natural gas

reservoirs, because the small molecules could escape too easily.

This is not the case, as a hydrogen accumulation is being exploited

in the region of Bourakebougou in Mali, producing electricity for

the local village.

Tested in 2012 from a capped wellbore machine-drilled for water in

1987, natural hydrogen flowed from below the plastic casing cemented

to the bottom of the wellbore. Analysis of this shallow GazBougou1

discovery well confirmed H2 gas at a concentration

of 98% purity, with traces of methane, and nitrogen. This is the

purest naturally occurring hydrogen ever discovered.

Further exploratory wells were drilled long after the first two

stratigraphic holes F1 and F2 had their cores studied to begin

defining the regional geological model for H2.

Mali’s natural hydrogen is gathered in

5 rock layers, trapped by subsurface lava flows. Deep, medium, and

shallow sources are believed to be at work to periodically refresh

the accumulations of geologic hydrogen. There are at least 7

possible mechanisms for the generation of hydrogen discussed in the

reference paper. There are many challenges in defining hydrogen

system logic, so there are still many unknowns.

This is where petrophysics comes to the rescue. Take a peek under

the rug and see what might be waiting below all those volcanics you

drilled through over the last 70 years. No, it won’t be easy, as you

probably will need faults to the basement and fractures, where well

logs can help there too.

It’s time for a paradigm shift for hydrogen!

Some scientists believe geologic hydrogen gas produced in Mali will

continue for thousands of years, sustainably decarbonising the local

community (even though they did not have much of a carbon footprint

to begin with). This is highly speculative as it may have taken

millions of years for the gas to accumulate.

Stratigraphic sequence of Mali natural hydrogen discovery (Ref 1)

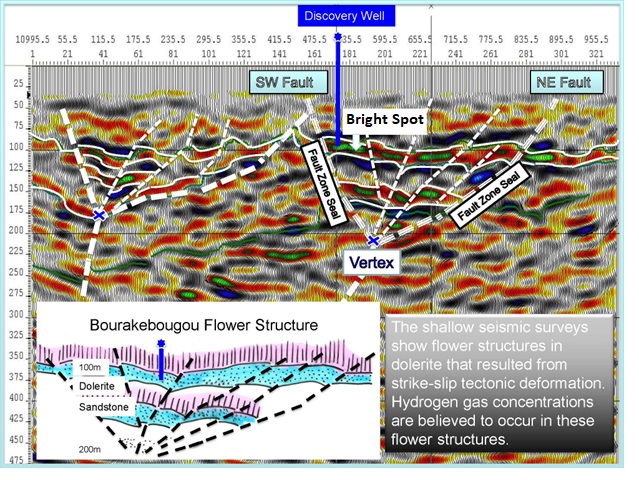

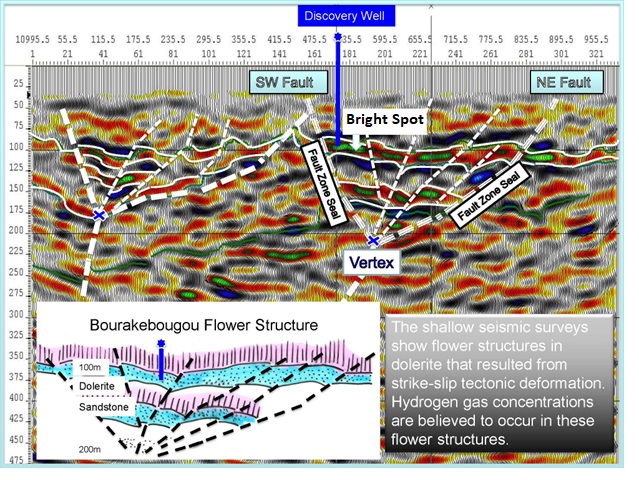

Seismic cross-section of Mali natural hydrogen discovery showing

“flower structure” (Ref 1)

Well log from typical Mali natural hydrogen discovery area (Ref 1)

Hydrogen from Radiolysis in Radioactive Rocks

Hydrogen from Radiolysis in Radioactive Rocks

The three long-lasting naturally occurring chemical elements in the mantle

and crust of the earth, Thorium-232, Uranium-238, and Potassium-40, decay

and give off radioactive particles. Half of the earth’s internal heat comes from

this radioactive decay.

- An isotope of Th-232 gives off alpha and beta particles with half-lives of 14 billion years.

- An isotope of Ur-238 gives off alpha particles with a half-life of 4.5 billion years.

- An isotope of K-40 gives off beta and gamma particles with half-lives of 1.25 billion years.

Beta particles have short interactive paths, and alpha particles have longer particle paths.

Gamma particles only interact once in a photoelectric capture.

When these radioactive particles strike water and surrounding rock matrix, the interaction

causes a removal of an electron from absorbing species all along the particle’s path as the

particle’s energy is depleted. This makes ions of all the absorbing species which quickly

become chemically reactive and subsequently interact with other nearby substances.

Some of the resulting chemicals from this subsequent reaction of radiolysis produce

molecular hydrogen, hydrogen peroxide, oxygen, and helium. It has been estimated that the

earth’s crustal and oceanic radiolytic hydrogen is produced at a rate of 0.47 x 1011 Moles/year.

These facts would indicate that hydrogen should be found in its native states in

radioactive rocks of any kind whether igneous or sedimentary. This includes, for example,

the Canadian shield, any igneous or metamorphic rocks. As of 2024 geological exploration of the

Canadian shield in Quebec is being undertaken to see if water and possibly hydrogen can actually

be located. This will use standard exploration techniques such as stratigraphic borehole drilling,

cores and sample collection. They may be logged with conventional or slimhole logging tools,

for example: gamma ray, sonic, density, neutron, and modern versions of induced gamma ray spectroscopy logs.

Water, if found, would be collected and sampled for its chemistry and hydrogen in solution.

Because we know of several hundred hydrogen seeps in the world it is possible this form of

exploration will find source for many more seeps of this kind. Over the next few years

exploration for this source of natural hydrogen may prove that hydrogen can be produce

at commercial quantities.

Potential

Organic SourceS of Natural Hydrogen

Potential

Organic SourceS of Natural Hydrogen

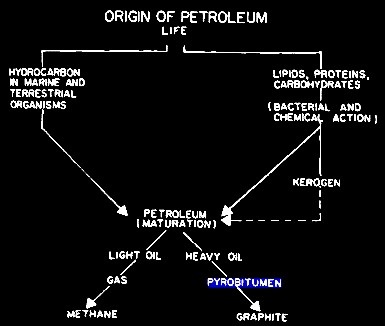

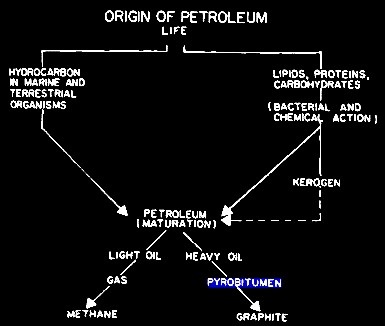

There are two possible geological processes that could

produce natural hydrogen from organic matter (petroleum).

Both involve a form of decomposition or “cracling” of

existing hydrocarbons at depth.

GRAPHITIZATION

The first is graphitization of pyrobitum, in which the final

product is pure graphite in the pore space. I actually

analyzed a 100+ foot graphite bearing limestone on Melville

Island in the Canadian Arctic back in the 1970s – drill

cuttings and an ohm-meter proved the presence of conductive

graphite. To get pure carbon, we need to lose the hydrogen

in a process called dehydrogenation or graphitization..

Evolution of hydrocarbon, showing formation of graphite at bottom

right. The hydrogen (not

shown) is free to move or to become bonded chemically or

physically in the rock.

The precursor for graphitization is pyrobitumen (petroleum coke).

Under high pressure and temperature (pyrolysis),

the coke

passes through a fluid stage (carbonization). This fluidity

facilitates the molecular mobility of the aromatic molecules,

resulting in intermolecular dehydrogenative polymerization reactions

to create aromatic, lamellar (disc-like) molecules. These

“associate” to create a new liquid crystal phase (meso-phase). A

fluid phase is the dominant requirement for production of

graphitizable carbons. Hydrogen is expelled during this

reorganization and is free to move elsewhere. This process was

described in 1951 by Rosalind Franklin.

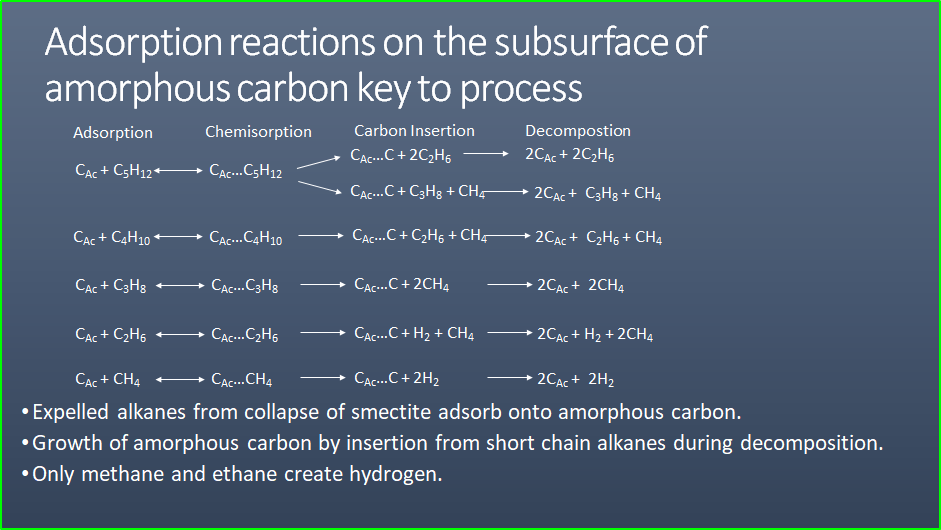

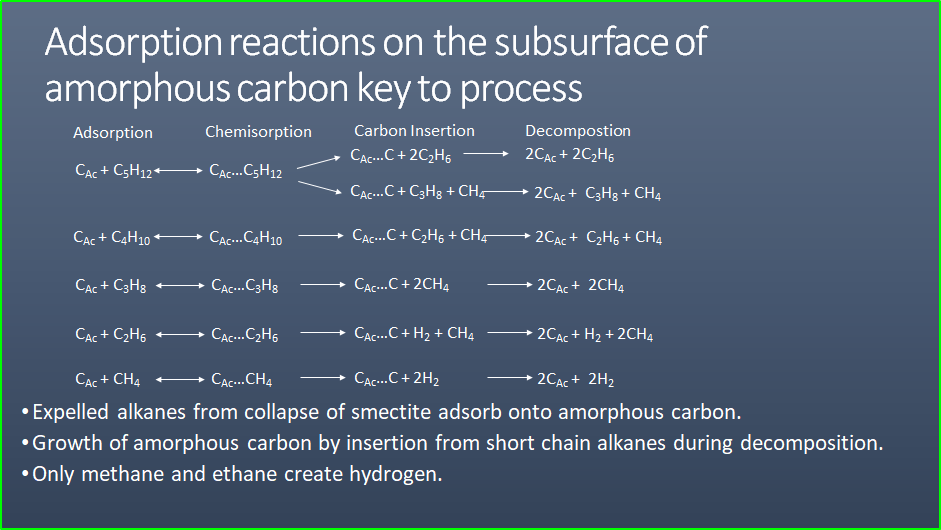

NatuRal Pyrolysis of Methane or Ethane

The second, more speculative, method was presented In June 2023 by

John Hanson at a symposium on natural hydrogen at the Geological

Socierty in London titled “Potential to Generate Organic Hydrogen”.

In it, he presents chemical equations that show how methane and

ethane can be converted into hydrogen by natural processes

underground, similar to industrial pyrolysis of methane. The

detailed mechanism is beyond the scope of this article, but John’s

slide presentation can be downloaded

HERE. This is very early work and no doubt revisions and

updates will appear in the literature

. .

Possible chemical pathways to organic hydrogen (CAC =

activated carbon)

MANUFACTURED HYDROGEN PRODUCTION

MANUFACTURED HYDROGEN PRODUCTION

There are over 200 chemical reactions that can produce

hydrogen, some dating back 150 years or so. None could be

considered “Green”. About 48% of commercial bulk hydrogen is

produced by the Steam Reforming Method (SRM), using natural

gas as a feedstock, with CO2

released to the atmosphere, or with carbon capture and

storage (CCS) to mitigate greenhouse gas (GHG) emissions.

Other sources of H2 are from by-products

of the manufacture of ammonia, methanol, and other

industrial chemicals, plus electrolysis of water or

pyrolysis of methane.

In 2012 the natural hydrogen discovery well was tested in

Mali and it has broadened the search for clean geologic

sources.

HYDROGEN PRODUCTION

FROM METHANE USING STEAM REFORMING

HYDROGEN PRODUCTION

FROM METHANE USING STEAM REFORMING

The most common method is reacting

water, in the form of super-heated steam (700 – 1100 C), with

methane to form carbon monoxide, which in turn causes the removal of

hydrogen from the methane. The water vapor is then reacted with the

carbon monoxide to oxidize it to carbon dioxide, turning the water

into hydrogen. The process is called Steam Reforming, also known as

the Bosch process. The chemistry is:

1: CH4 + H2O

→ CO + 3 H2

2:

CO + H2O → CO2

+ H2

This reaction is favoured at low pressures but is usually conducted

at high pressures (2.0 MPa). This is because high pressure H2

is the most marketable product, and pressure swing adsorption (PSA)

purification systems work better at higher pressures. The product

mixture is known as "synthesis gas" because it is often used

directly for the production of methanol and related compounds.

HYDROGEN PRODUCTION FROM ELECTROLYSIS OF WATER

HYDROGEN PRODUCTION FROM ELECTROLYSIS OF WATER

When a direct current is run through water, oxygen forms at

the anode (+) while hydrogen forms at the cathode (-).

Typically the cathode is made from platinum or another inert

metal. While this is a proven technology, it supplies only

5% of the World’s demand for hydrogen.

The method presumes that an adequate supply of unallocated

fresh water, (or desalinated sea water or medium depth

oilfield brine) and a source of unallocated electricity can

be found. In many areas, fresh water is already in short

supply and additional draws on surface or near surface water

may be impossible. Deeper sources may also be restricted.

See “Analyzing Water Wells

”

to learn how to locate potential underground sources of

water.

The chemistry for electrolysis is pretty simple:

3: 2 H2O + electricity → 2 H2

+ O2 + heat

Theoretical efficiency (electricity used vs. energetic value of

hydrogen produced) is between 88 to 94% with no impurities in the

water, much less if desalinization is needed. Energy costs of

compression, storage, and transportation to market are also not

included.

HYDROGEN PRODUCTION FROM METHANE PYROLYSIS

HYDROGEN PRODUCTION FROM METHANE PYROLYSIS

Natural gas (methane) pyrolysis is a one-step process that produces

no greenhouse gases. Developing volume production using this method

is the key to enabling faster carbon reduction by using hydrogen in

industrial processes, fuel cell electric heavy truck transportation,

and in gas turbine electric power generation.

Pyrolysis is achieved by having methane (CH4)

bubbled up through a molten metal catalyst containing dissolved

nickel at 1,070 C. This causes the methane to break down into

hydrogen gas and solid carbon, with no other by-products (except

those from maintaining the reactor at the high temperature

required).

The chemistry is deceptively simple, but implementation is tricky.

4: CH4 + heat + catalyst

→ C + 2 H2

The industrial-quality solid carbon may be sold as manufacturing

feedstock or permanently landfilled, it is not released into the

atmosphere and there is no ground water pollution in the landfill.

Methane pyrolysis is in development and considered suitable for

commercial bulk hydrogen production, assuming low-cost methane is

available as both feedstock and heat source. Further research

continues in several laboratories and at least one pilot project.

NATIVE HYDROGEN

FROM SERPENTINIZATION REACTIONS

NATIVE HYDROGEN

FROM SERPENTINIZATION REACTIONS

The hydrogen in the Mali example may have come from a deep

source from mantle degassing, a moderate depth source from

rock crushing in faults, or a shallow source from chemical

serpentinization.

Serpentinization is a form of low temperature metamorphism driven

largely by hydration and oxidation of olivine and pyroxene, creating

serpentine minerals brucite, and magnetite. Under the unusual

chemical conditions accompanying serpentinization, water is the

oxidizing agent, and is itself reduced to hydrogen. This leads to

further reactions that produce rare iron group native element

minerals, such as awaruite and native iron, methane, and other

hydrocarbon compounds, and hydrogen sulphide.

During serpentinization, large amounts of water are absorbed into

the rock perhaps during intense rainy seasons, increasing the

volume, reducing the density and destroying the original rock

structure. The density changes from 3.3 to 2.5 gm/cc with a

concurrent volume increase on the order of 30 to 40%. The reaction

is highly exothermic and rock temperatures can be raised by about

260°C, providing an energy source for the formation of

non-volcanic hydrothermal vents.

Hydrogen is produced during the process of serpentinization. In this

process, water protons (H+) are reduced by ferrous (Fe2+)

ions provided by fayalite (Fe2SiO4).

The reaction forms magnetite (Fe3O4),

quartz (SiO2), and hydrogen (H2).

5: 3 Fe2SiO4 + 2

H2O → 2 Fe3O4

+ 3 SiO2 + 3 H2 +

heat

fayalite + water → magnetite + quartz +

hydrogen

Laboratory studies of serpentinization at high temperature and

pressure show how methane could be produced, lending some credence

to deep-seated gas and oil generation and migration.

6: 18 Mg2SiO4

+ 6 Fe2SiO4

+ 26 H2O +

CO2 →

12 Mg3Si2O5(OH)4

+4 Fe3O4

+ CH4

forsterite + fayalite + water +

carbon dioxide → serpentine + magnetite +

methane

My grade 9 chemistry class didn’t get much past 2H2

+ O2 → 2 H2O,

but equation 6 looks OK to me.

Ocean seeps show both hydrogen and methane emissions. We just have

to find them on land, complete with a hydrogen accumulation, as in

the Mali example. There are more than 100 published reports of

natural hydrogen seeps on land in a dozen countries, treated as

curiosities across many years. Maybe they will lead to a new

industry, just as the oil seeps of antiquity did. (Reference:

Wikipedia)

ACKNOWLEDGEMENT

Thanks to Denis Briere of Chapman Petroleum Engineering Ltd for

contributing information and suggestions for this article, including

illustrations in Figures 3, 4, and 5.

REFERENCES

1. On generating a geological model for hydrogen gas in the

southern Taoudeni

Megabasin, Bourakebougou area, Mali” ACS Letters, 12 June 2016

Denis Briere and Tomasz Jerzykiewicz,

https://doi.org/10.1190/ice2016-6312821.1

2. Hydrogen and Hydronium, Chem-Libre, 2022

https://chem.libretexts.org/Bookshelves/General_Chemistry/Book%3A_ChemPRIME_(Moore_et_al.)/11%3A_Reactions_in_Aqueous_Solutions/11.05%3A_Hydrogen_and_Hydroxide_Ions

3. Hydrogen and Hydronium Technical Data, Production Methods, Serpentinization

Various Wikipedia pages

|

.

.