|

LATEROLOG BASICS

LATEROLOG BASICS

This page describes laterologs

profiles, in the order of their appearance over the years.

This presentation style provides insights into tool

evolution, and a specific tools capabilities and

limitations. You will find most these tool types in your

well files heres your chance to learn more about them.

The laterolog was put into service in 1949, predating

the induction log by 6 or 7 years, as a replacement for the ES Log

in salt mud environments. It was another invention by Henry Doll of

Schlumberger. Competitive tool designs were called Guard Logs or

Focused Logs. The objective was to focus the current from the tool

into the rock better than could be accomplished with the ES Log.

Tool designs evolved significantly over the years and modern tools

are in widespread use in both salt and fresh mud environments.

Laterologs work best in saltier muds or in normal

muds in high resistivity formations. They will not work in air

filled or cased holes

The laterolog is a direct current (DC)

tool based on Ohm's Law. The

tools have been

designed to produce reliable resistivity measurements in boreholes

containing highly saline drilling fluids and/or when surrounded

by highly resistive rocks. The logging current is prevented

from flowing up and down within the drilling fluid by placing

focusing electrodes (A1 and A2) on both sides of a central measure

electrode A0, as illustrated below. The focusing electrodes

force measure current to flow only in the lateral direction,

perpendicular to the axis of the logging device.

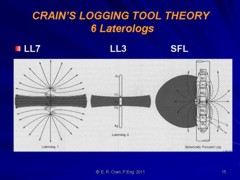

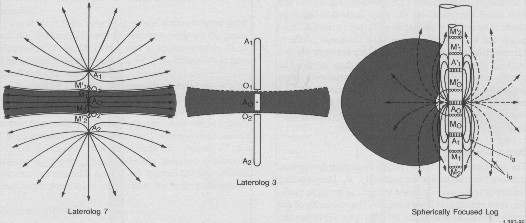

Schematic diagrams of laterolog 7 (left), laterolog

3 or Guard log (middle) and spherically focused log (right). Grey shading

represents desired current path. The Laterolog 7 electrode

arrangements can be likened to two ES logs spliced together,

with one tool upside down. The center current electrode A0 is in

the middle of the current path. Guard electrodes A1 and A2 keep

the current focused. On the LL7, measure electrode pairs M1 and

M2 straddle the top and bottom current path boundary. The secret

is to keep the current flow constant to get an accurate

resistivity.

LATEROLOG SCALES

LATEROLOG SCALES

CAUTION:

Older laterologs had unusual resistivity scales. Some

were linear with multiple backups, eg 0-100, 0-1000, 0-10000. Others

used a hybrid scale that managed to compress resistivity from zero

to infinity into a single track with no backups. Look at the example

below

to see how it was done. Logarithmic scales appeared for the dual

laterolog and later tools to eliminate these problems. A backup

scale is still possible.

EXAMPLE

OF A HYBRID RESISTIVITY SCALE:

RESD=> 0 20 40 60

80 100 125 167 250 500 INF <=COND/1000

|____|____|____|____|____|____|____|____|____|___ |

| | |

| |

|

COND=>

10 8 6 4

2 0 <=COND

A hybrid scale was part linear, part non- linear for exanplf 0

100 infinity across 1 or 2 tracks. The 0 100 part was linear

resistivity; the 100 infinity part was actuslly a 10 0

conductivity scale, Digital data vendors often digitized these logs

incorrectly, leading to rediculous water saturation calculations.

The standard scales were:

RESD scale 0 500 infinity, COND portion 2 0

RESD scale 0 200 infinity, COND portion 5 0

RESD scale 0 100 infinity, COND portion 10 0

RESD scale 0 50 infinity, COND portion 20 0

RESD scale 0 25 infinity, COND portion 40 0

Solution: assume the midpoint scale value = MID.

This makes RESD scale 0 MID infinity and COND portion 1000/MID

0

Digitize 0 MID as linear resistivity from left margin to middle of

track as a RESD curve. Then digitize 1000/MID 0 linear

conductivity from middle of tracks to right margin as a COND curve.

Convert COND to to residtivity:

1: RESDc = 1000 / COND.

Merge the 2 curves:

2: IF (RESD <= MID) THEN RESDfinal = RESD

3: IF (RESDc > MID) THEN RESDfinnal = RESDc.

Note too that the SP was recorded 40+/- feet off depth and that part

of the log was sliced off and spliced back "on depth", if someone

remembered to do the task. Since the tools were run mostly in salt

mud and SP is not much use in salt mud, not a lot of attention was

paid to this problem. I tried to fix this in 1964 using the GR

memorizer panel. It worked on the bench but not at the wellsite due

to stray ground currents.

References:

1. The Laterolog: A New Resistivity Logging Method With Electrodes Using

an Automatic Focusing System

H.G. Doll, Journal of Petroleum Technology, 1951

2. Dual Laterolog - Rxo Tool

J. Suau, P. Grimaldi, A. Poupon, P. Souhaite,

AIME, 1972

EARLY

LATEROLOGS (LL3, LL7, Gaurd Logs, FoRxo Logs)

EARLY

LATEROLOGS (LL3, LL7, Gaurd Logs, FoRxo Logs)

There are two major types of laterologs:

three electrode guard systems and multiple electrode systems.

Guard systems utilize two elongated focusing (guard) electrodes

(A1 and A2 and a small center measure electrode

A0. Zero potential difference is maintained between the center

and guard electrodes during logging. Resistivity is proportional

to the potential (voltage) on the center electrode, as shown

mathematically later in this Section.

Seven electrode systems have an additional

two pairs of small electrodes placed symmetrically on both

sides of the center electrode (M1 – M1’ and M2 – M2’).

The zero potential difference is maintained between these additional

electrodes. Seven electrode systems include the obsolete LL7

style tool.

Bed resolution of the above tools is 3 feet, considerably

better than the 64 inch Normal and most induction logs (except the

array induction).

In all guard systems, the zero potential

difference between the center electrode and the guard electrodes

prevents current emanating from the center electrode from flowing

along the borehole even when it contains highly saline mud.

Thus, the measure current will assume the shape of a cylindrical

disc.

A Canadian company, Roke Oil Enterprises Ltd, developed a

laterolog in the 1970's so stable that it could keep a zero potential difference

even in cased holes, allowing the measurement of resistivity through

casing. Thirty years later, the majors produced their own

through-casing resistivity tools.

The thickness of this current disc

is approximately equal to the length of the center electrode

plus one-half the distances separating it from each of the

guard electrodes.

The current density varies inversely with

the radial distance and can be calculated from:

1: Current density

= I / (2 * PI * R * T)

Where,

I

= total current intensity (amperes)

T = thickness

of measure current disc (meters)

R = radial

distance (meters)

Resistivity

of the formation is:

2: Rt = K * V / I (same as ES log except

K is different)

Where

V = potential of measure

electrode (volts)

I = current flow from measure

electrode (amperes)

K = a calibration constant

defined by the geometry of the electrode spacing

The path taken by the measure current of a laterolog

constitutes a series circuit through the drilling mud, mud

cake, flushed and invaded zones, and the undisturbed formation.

In a series circuit, the total resistivity is the sum of resistivities

along the current path.

The pseudo-geometrical factor concept

was developed to estimate the influence of these zones on the

measured apparent resistivities, in a manner similar to that

described earlier for the induction log. Both borehole and

bed thickness correction charts are available in service company

chartbooks, based on computer models of the pseudo-geometrical

factors for each tool design.

DUAL LATEROLOG (DLL)

DUAL LATEROLOG (DLL)

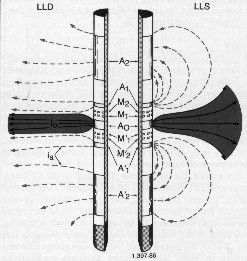

Dual

laterolog tools use 9 electrodes.

Additional A1’ and

A2’ electrodes provide greater guard electrode coverage

than a single upper and lower guard. Different depths of investigation

are created by controlling the potential on the outermost guard

electrodes. Shaded area at the

right shows desired current paths. Dual

laterolog tools use 9 electrodes.

Additional A1’ and

A2’ electrodes provide greater guard electrode coverage

than a single upper and lower guard. Different depths of investigation

are created by controlling the potential on the outermost guard

electrodes. Shaded area at the

right shows desired current paths.

The two depths of

investigation are recorded alternately so that the currents do not

interfere with each other, but quickly enough that both look like

continuous logs. An early version of this tool was called a

sequential dual laterolog; here a switch could be set while the tool

was downhole to select one or the other electrode set, but it took

two passes over the logged interval to obtain both logs.

The two curves were called "shallow" and "deep" by the service

companies, but from a depth of investigation point of view, they

were

treated as "medium" and "deep", although not as deep as a dual

induction log in its fresh mud environment. If a shallow resistivity

was required, an MSFL or MLLC log was run as a separate pass into

the hole.

LATEROLOG 8 (LL8) and SPHERICALLY FOCUSED LOG (SFL)

LATEROLOG 8 (LL8) and SPHERICALLY FOCUSED LOG (SFL)

The Laterolog 8, with 8 electrodes,

was designed to replace the 16 inch normal on the induction log when

it was re-introduced as the dual induction log. It had better bed

resolution and less borehole effect, and survived in saltier muds

than its predecessor.

It was replaced after a few years by the spherically focused log,

which is 9 electrode

system, but the electrodes are arranged to place the guards

closer to the center electrode, and the equalizing electrodes

further away. Its response was believed to give a better

impression of the shallow resistivity in the flushed zone (Rxo).

HIGH RESOLUTION ARRAY LATEROLOG (HRL)

HIGH RESOLUTION ARRAY LATEROLOG (HRL)

Newer laterologs are called high resolution laterolog

and azimuthal resistivity log, replacing those described

above. The high resolution tool has 5 depths of investigation,

similar to the array induction log presentation. Typical bed

resolution is 2 feet, and the high resolution curve can

resolve 8 inch beds.

AZIMUTHAL RESISTIVITY IMAGE LOG (ARI)

AZIMUTHAL RESISTIVITY IMAGE LOG (ARI)

The azimuthal tool records resistivity in 8 directions

radially around the wellbore. In a vertical well, this may not have

great impact, although the image can show bed boundaries, dip angle

and direction, and fractures very well. Composite deep and shallow

resistivities are recorded.

In a horizontal well, it has serious uses. Looking

up, the tool might see the cap rock (low resistivity for shale, high

resistivity for anhydrite). Looking down, the tool might see low

resistivity for water or high resistivity for more pay. Sideways,

the tool should be looking at the pay zone.

The 8 azimuthal resistivities can be presented as an image

log, similar in appearance to a resistivity microscanner image. It

has coarse vertical and horizontal resolution compared to the

microscanner, but is considerably cheaper to run.

Cased Hole

Formation Resistivity (CHFR)

Cased Hole

Formation Resistivity (CHFR)

Cased hole

formation resistivity logs make direct, deep reading resistivity

measurements through casing and cement. The concept of measuring

resistivity through casing is not new, but recent breakthroughs in

downhole electronics and electrode design have made these

challenging measurements possible. Now the same basic measurements

can be compared for open and cased holes.

The

effects of invasion are usually dissipated by the time the log is

run, so the measurement is considered to be a good representation of

true resistivity, as long as cement conditions are adequate.

The

tool injects current into the casing with sidewall contact

electrodes, where it flows both upward and downward before returning

to the surface along a path similar to that employed by open hole

laterolog tools. Most of the current remains in the casing, but a

very small portion escapes to the formation. Electrodes on the tool

measure the potential difference created by the leaked current,

which is proportional to the formation conductivity.

Typical formation resistivity values are about 10^9 times the

resistivity value of the steel casing. The measurement current

escaping to the formation causes a voltage drop in the casing

segment. Because the resistance of casing is a few tens of microohms

and the leaked current is typically on the order of a few

milliamperes, the potential difference measured by the CHFR-tool is

in nanovolts.

LATEROLOG CURVE NAMES

LATEROLOG CURVE NAMES

Laterolog /

Guard Log (LL7, LL3)

Laterolog /

Guard Log (LL7, LL3)

|

Curves |

Units |

Abbreviations |

| deep

laterolog resistivity |

ohm-m |

RLL

or RESD |

| gamma

ray |

API |

GR |

| spontaneous

potential |

mv |

SP |

Dual Laterolog Simultaneous Type (DLL)

Dual Laterolog Simultaneous Type (DLL)

|

Curves |

Units |

Abbreviations |

| deep

laterolog resistivity |

ohm-m |

LLD

or RESD |

| shallow

laterolog resistivity |

ohm-m |

LLS or RESM |

| spontaneous

potential |

mv |

SP |

| gamma

ray |

api

|

GR |

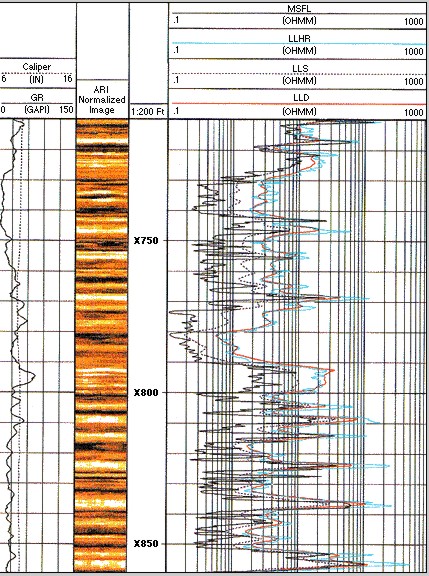

Azimuthal Resistivity Log (ARI)

Azimuthal Resistivity Log (ARI)

|

Curves |

Units |

Abbreviations |

| deep

laterolog resistivity |

ohm-m |

RLLD

or RESD |

| shallow

laterolog resistivity |

ohm-m |

RLLS or RESM |

| high

resolution laterolog resistivity |

ohm-m |

LLHR

or RESD |

| *

resistivity image, colour |

|

|

| *

8 individual azimuthal resistivity curves |

|

|

| *

directional survey data |

|

|

| *

spontaneous potential |

mv |

SP |

| *

gamma ray |

API |

GR |

High

Resolution Array Laterolog (HRL)

High

Resolution Array Laterolog (HRL)

|

Curves |

Units |

Abbreviations |

| two

foot resistivity 10 inch depth |

ohm-m

|

HRLA1

(RESS) |

| two

foot resistivity 20 inch depth |

ohm-m |

HRLA2 |

| two

foot resistivity 30 inch depth |

ohm-m |

HRLA3

(RESM) |

| two

foot resistivity 60 inch depth |

ohm-m |

HRLA4

|

| two

foot resistivity 90 inch depth |

ohm-m |

HRLA5

(RESD) |

| *

invasion profile image, colour |

|

|

| *

spontaneous potential |

mv |

SP |

| *

gamma ray |

API |

GR |

EXAMPLES OF LATEROLOGS

EXAMPLES OF LATEROLOGS

Like all other logs, laterologs have come in many

flavours and styles over the years. Below are examples of older logs

that you will find in well files from earlier times.

Sample Laterologs, with gamma ray, showing hybrid

resistivity scale (left) and logarithmic scale

(right) over same wellbore interval. Many varieties of Laterolog are run today,

some with a dozen or more resistivity curves.

The hybrid scale was run from 1950 into the 1970's. It is

composed of a linear resistivity scale running from 0.0 on the

left to 50 or 100 ohm-m in the middle of the track. From the

middle of the track to the right hand margin, the curve is

actually a linear conductivity scaled from 20 to 0 or 10 to 0

milli-mhos. These two scales are equivalent to a 50 to infinity

or 100 to infinity resistivity scales. These combined curves

give the hybrid scale a continuous resistivity range from 0 to

infinity across one or two tracks. The conductivity curve was

also presented on some logs. The hybrid scale was replaced by

the logarithmic scale in the 1970's, which may have backup

scales because of the high range of resistivity that can be

measured with this tool.

The SP curve may be present, but it may be pretty flat because

laterologs were usually run in salt mud. The SP track may be shifted

by splicing the film, as the curve was recorded 28 feet off-depth on

some tools. Newer logs usually have a gamma ray curve in Track 1

instead of the SP.

RESISTIVITY IMAGES FROM

MODERN LATEROLOGS

RESISTIVITY IMAGES FROM

MODERN LATEROLOGS

Azimuthal resistivity image logs

(a form of laterolog) and high resolution laterologs can be

displayed as images as well as resistivity curves.

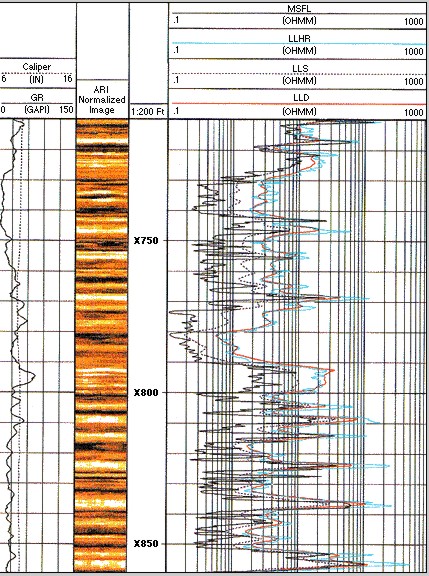

Below is a sample of an array induction (AIT) log and an azimuthal

resistivity (AIR) log, the latter showing the azimuthal image log

presentation.

Comparison of array induction log (left) and azimuthal resistivity laterolog (right). Curve complement and

presentations vary considerable with age and contractor. The image

log on the azimuthal resistivity presentation is "poor man's"

resistivity microscanner log, giving a reasonable sand count

regional dip, and some fracture information. A real microscanner

image is shown for comparison (left image).

High resolution laterolog showing deep invasion and high

resolution image.

All curves are focused to

about 8 inches. This tool is not azimuthal so image shows flat-lying

beds even when dip is present.

|