|

ACOUSTIC IMAGE LOG BASICS

ACOUSTIC IMAGE LOG BASICS

This page describes acoustic image

logs profiles, in the order of their appearance over the

years. This presentation style provides insights into tool

evolution, and a specific tool’s capabilities and

limitations. You will find most these tool types in your

well files – here’s your chance to learn more about them.

Acoustic image logs are an economic replacement for resistivity

image logs for assessing structure

and stratigraphy of reservoir rocks and for Identification of

fracture intensity and fracture orientation. Tool design has improved

considerably since its introduction. Acoustic image logs are

identified by numerous tradenames that might not easily be

recognized, such as continuous borehole image log (CBIL) and

ultrasonic borehole imaging log (UBI).

This tool is sometimes called a borehole televiewer but it should not be

confused with borehole television systems that can take continuous

video images of a wellbore filled with a clear liquid or air.

The

acoustic image log provides formation images in liquid filled open holes. In cased hole, the same tool

is used as a cement and pipe integrity tool, but it does not provide

any reservoir property information.

The tool

has roots back to the 1970's and uses a rotating acoustic

transducer/receiver operating at ultrasonic frequencies. The

travel time of the sound from the transducer to the wellbore

wall and back to the receiver is measured. This provides a

complete image of wellbore diameter (a caliper log). Black colour indicates large diameter, white is "near" bit size.

Fractures and wellbore breakout are easily seen (black). The

poor resolution on older tools makes these artifacts larger than

life and were quite misleading as to the width of fractures.

Even modern logs exaggerate fracture width.

The

log also records the amplitude of the sound signal reflected from

the borehole wall. This is a measure of the acoustic impedance of

the rock. Low values represent shale or soft sandstone (shaded black

on the log) and high values represent competent rock such as

cemented sandstones or carbonates (shaded white on the log).

Fractures and breakout will appear black, as on the caliper image.

Colours or grey-scales can be stretched or squeezed to enhanced particular

features. Dipping beds appear on the image as sine-wave patterns.

The amplitude of the sine-wave indicates dip angle and the valley of

the sine-wave indicates downdip direction.

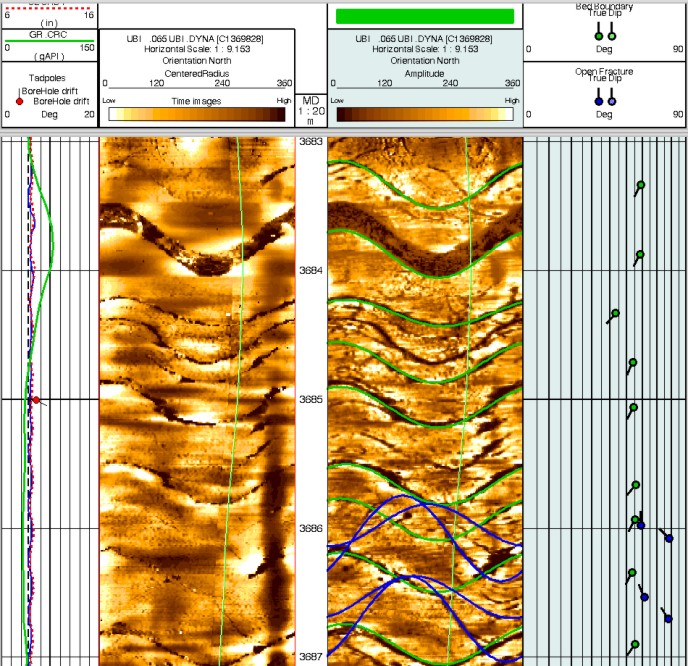

Ultrasonic (acoustic) image log;

travel time image (left) indicates borehole diameter, amplitude

image (right) shows acoustic impedance, dips calculated from image

show both bedding (green) and fracture (blue) dips. The dark areas

on the travel time image show borehole elongation in the NW-SE

direction, with maximum stress direction at right angles to this

axis. On real logs, check heading carefully, as travel time and

amplitude images can be interchanged in position, and North may be

on the right or the middle of the track.

A

resistivity image log has about 10 times the spatial resolution of an

acoustic image log

and 500 times the amplitude resolution, due to the difference

in contrast between the resistivity and acoustic impedance ranges

measured by the respective tools.

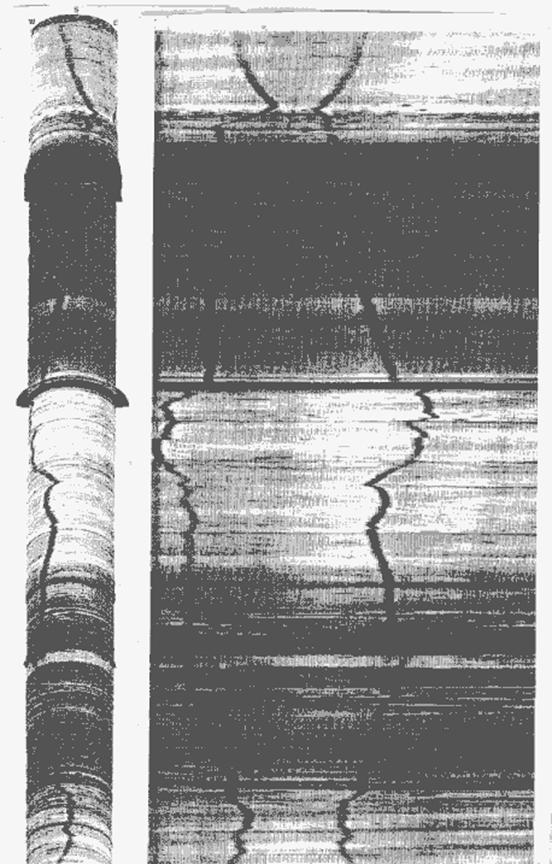

Comparison of resistivity image

log (left) and ultrasonic image log in the same borehole. The higher

spatial resolution and the higher dynamic range of the resistivity

image is clear. Black colour represents low acoustic impedance on

CBIL/ UBI, or low resistivity on FMI, in this case representing

fractures (near vertical) or shale beds (near horizontal).

OLDER

ACOUSTIC IMAGE LOGS

OLDER

ACOUSTIC IMAGE LOGS

Older acoustic image logs have even

poorer resolution than current versions. If you are working with

older logs that exist in the well files, be cautious in using them.

Fracture apertures are usually extremely over emphasized.

Older acoustic image log (left) and interpretation

image (right). The large apparent fractures seen on older logs

led many people to believe that fracture apertures were very

large (many millimeters), when they are really quite small (less

than a millimeter).

The

resolution of the tool allows us to determine events of about

10 mm in width. Fractures are often accentuated in the wellbore

by the drilling process, which breaks out the fracture on both

sides of the opening. If it were not for this breakout, most fractures

would not be seen by the acoustic imaging log, as their width is

commonly less than 1 mm.

Considerable

research has being conducted to enhance the images,

using both arrival time and amplitude of the sound waves, plus

computer methods for image enhancement, especially edge enhancement

to resolve fractures and bed boundaries. Modern acoustic image logs

can be used effectively in more rugged boreholes than older versions

because of the new processing techniques. Be aware of the age

of the log before you start your analysis.

The

example below shows an older acoustic image log over a portion of a hole

with a vertical fracture intersecting the borehole. The image

is displayed as a 360 degree unwrap with East at the center of

the image, and as an equivalent core image, with South in the

middle.

Acoustic image in vertical fracture in a vertical

hole

Notice

the enlarged borehole in some of the thin shale beds. The fracture

plane is far from smooth and it wanders from one side of the borehole

to the other. A dipmeter or older FMS might miss this fracture,

or indicate discontinuous vertical fractures. Light colors are

higher acoustic impedance, probably dolomite versus darker colored

limestone and limey shales. Shale beds are black and washed out.

Below is

a drill pipe conveyed acoustic image log run over a 1500 foot horizontal

stretch from the intermediate casing shoe. The zone is an upper

Cretaceous chalk in which fractures play a vital role in productivity.

Most vertical wells penetrate only one or two fractures and deplete

quickly. A horizontal well can penetrate many fractures and production

can be significantly enhanced.

Acoustic image log with vertical fracture in a horizontal

hole

The

acoustic image and uranium precipitation shown on the spectral

gamma ray log indicate fractures clearly (top image in

illustration above).

This allows the operator to position completion hardware, such

as centralizers and external inflatable casing packers correctly.

In this example, the hole was designed to run close to the top

of the chalk, and it penetrated the marly zone above in a few

places, shown by the dark bands (lower image in illustration

above).

LWD

ALTERNATIVES TO

ACOUSTIC IMAGE LOGS

LWD

ALTERNATIVES TO

ACOUSTIC IMAGE LOGS

Aside

from open hole resistivity image logs, there are other alternatives

to acoustic images. Aside

from open hole resistivity image logs, there are other alternatives

to acoustic images.

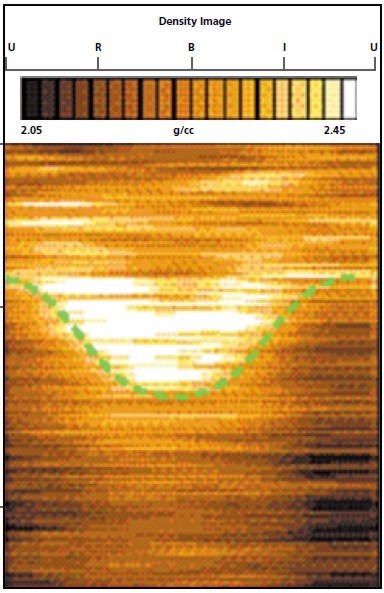

Logging while drilling (LWD) offers many alternatives that can be

displayed as an image log. The example at right is a density image

log. Low density values are shaded dark and can be interpreted as

porosity or shale. A gamma ray log run with the drill string helps

distinguish between these alternatives. White colours represent low

porosity or tight rocks.

Resistivity and acoustic images

are currently in the field testing stage and may become commercial

as LWD logging tools.

|