|

Reservoir Quality from Net Reservoir

Reservoir Quality from Net Reservoir

There are a number of ways to assess reservoir quality. In laminated

sands, one approach is to correlate first three months or first

year production with net reservoir properties from the laminated

models described above. We chose to use the first 8760 hours of

production (365 days at 24 hours each) divided by 4 (3 months

of continuous production) as our “actual” production

figure. This normalizes the effects of testing and remedial activities

that might interrupt normal production.

The normalized initial production was correlated with net reservoir

thickness, pore volume (PV), hydrocarbon pore volume (HPV), and

flow capacity (KH) from the laminated Model C. Correlation coefficients

(R-squared) are 0.852, 0.876, 0.903, and 0.906 respectively. The

correlation is made using data calculated over the total perforated

interval. The other three analysis models did not give useful

correlations nor did model C when only a single shale indicator

was used. Results of the correlations are shown below.

Average

shale volume was correlated with actual production but the correlation

coefficient was only 0.296, although the trend of the data is

quite clear.

Reservoir Quality from an Enhanced Shale Indicator Reservoir Quality from an Enhanced Shale Indicator

Another approach is to calculate a quality curve:

1. Qual2 = RSH * GR / RESD

This

amplifies the shale indicator in cleaner zones and is scaled the

same as the GR curve. A net reservoir cutoff of Qual2 <= 50

on this curve was a rough indicator of first three months production,

but the correlation coefficient was as poor as for average shale

volume. QUAL2 does make a useful curve on a depth plot as it shows

the best places to perforate when density and neutron data are

missing.

Reservoir Quality from Hester’s Number Reservoir Quality from Hester’s Number

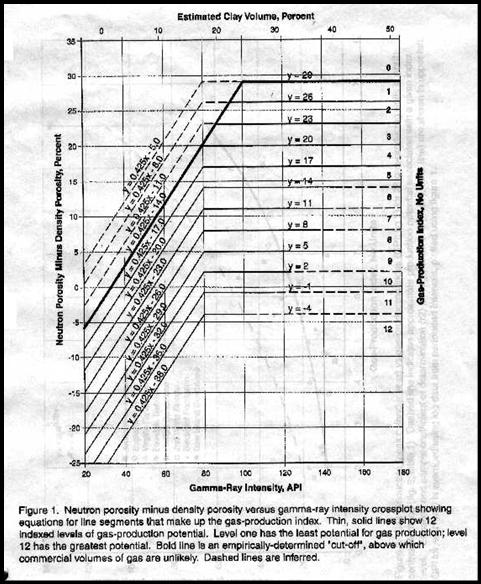

Another quality indicator was proposed by Hester (1999). It

related neutron-density porosity separation and gamma ray

response to production, based on the graph shown below..

Hester’s reservoir quality indicator (QUAL1)

This

graph is converted to a numerical quality indicator (Qual1) in

a complex series of equations that represents predicted flow rate.

The

equations, as displayed in the Lotus 1-2-3 spreadsheet are as

follows:

1:

ND_DN = 100 * (PHIN - PHID)

2: E = @IF(ND_DN>(0.425*GR)-14,0,@IF(ND_DN>(0.425*GR)-17,4,

@IF(ND_DN>(0.425*GR)-20,5,@IF(ND_DN>(0.425*GR)-23,6,

@IF(ND_DN>(0.425*GR)-26,7,@IF(ND_DN>(0.425*GR)-29,8,

@IF(ND_DN>(0.425*GR)-32,9,@IF(ND-DN>(0.425*GR)-35,10,11))))))))

3: F = @IF(ND_DN>(0.425*GR)-35,0,@IF(ND_DN>(0.425*GR)-38,11,12))

4: G = @IF(ND_DN>(0.425*GR)-14,0,@IF(ND_DN>29,0,@IF(ND_DN>26,1,@IF(ND_DN>23,2,@IF(ND_DN>20,3,

@IF(ND_DN>17,4,@IF(ND_DN>14,5,0)))))))

5: H = @IF(ND_DN>14,0,@IF(ND_DN>11,6,@IF(ND_DN>8,7,@IF(ND_DN>5,8,

@IF(ND_DN>2,9,@IF(ND_DN>-1,10,@IF(ND_DN>-4,11,12)))))))

6: I = @IF(E=0,F,E)

7: J = @IF(G=0,H,G)

8: QUAL1 = @IF(GR<80,I,J)

Where:

ND_DN = neutron minus density porosity difference in sandstone

units (percent)

PHID = density porosity sandstone units (fractional)

PHIN = neutron porosity sandstone units (fractional)

GR = gamma ray (API units)

QUAL1 = Hester Quality Number (unitless)

E, F, G, H, I, J = intermediate terms

Note

that these nested IF statements are slightly different than those

originally published by Hester. The changes correct for typographical

errors in the original paper.

There

is a flaw in Hester’s paper that can be cured. He does not

account for zone thickness or attempt to find a net reservoir

number. He uses only the average quality number over the zone,

which presupposes that all perforated intervals are equal in thickness.

To overcome this, we can use a quality cutoff and obtain a thickness

weighted quality and correlate this to actual production.

A

Hester quality of 4.0 or higher reflects reservoir rock that is

worth perforating, and gives similar net reservoir thickness as

the previous indicators. Graphs showing the correlation of actual

production to net reservoir with QUAL1 >=5 and >=4 are shown

below. The regression coefficients are 0.856 and 0.837

respectively. Although this looks pretty good, the low rate data

is clustered very badly and other indicators work better in low

rate wells.

The

Hester quality number QUAL1, along with QUAL2 = GR / RESD, are

the only quality indicators that show where to perforate. The

other indicators described here give a reasonable estimate of

reservoir performance, but do not give any indication of how to

economically complete the well.

Reservoir Quality from Productivity Estimates Reservoir Quality from Productivity Estimates

A productivity estimate based on a log analysis version of the

productivity equation has also proven useful The equation used was:

1. ProdEst = 6.1*10E-6 * KH * ((PF - PS)^2) / (TF + 273) * FR

* 90

The

leading constant takes into account borehole radius, drainage

radius, viscosity, and units conversions. KH is flow capacity

in md-meters. (PF - PS) is the difference between formation pressure

and surface pressure in KPa. A constant value of 1300 KPa was

assumed for this study. Clearly, more detailed data could be used

if time permits. TF was chosen constant at 20 degrees Celsius.

FR

is a hydraulic fracture multiplier, chosen as 2.0 for this study,

based on the 9 wells used to calibrate to 3-month initial production

data. The constant 90 converts e3m3/day into an estimated 3-month

production for comparison to actual. The 3 month numbers were

chosen instead of daily rate as they have more “heft”

and can be equated to income more readily.

Note that

the equation used is a constant scaling of KH, so the correlation

coefficient is the same as the KH graph at 0.906.

Case History - Milk River, Alberta

Case History - Milk River, Alberta

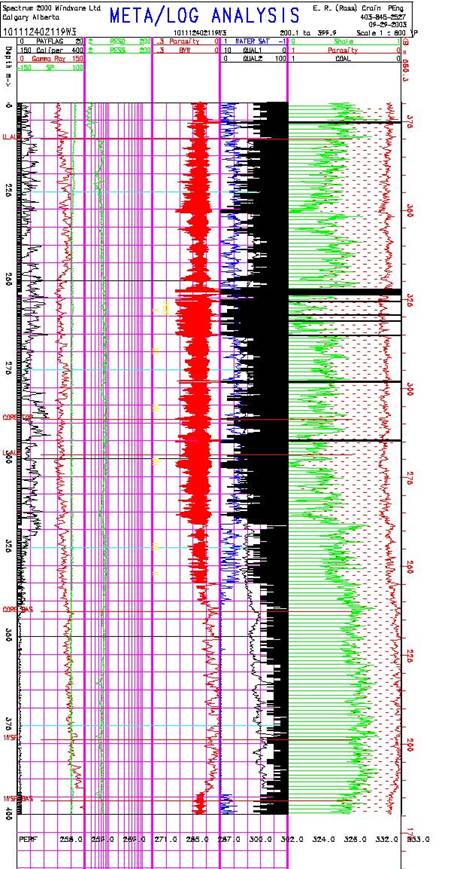

The sample depth plot

below shows typical results of

the prototype analysis. The majority of the results are from the

conventional analysis Model A, including the PayFlag. Some of

the input curves are shown in Tracks 1 and 2. Hester’s quality

factor (QUAL1) and the GR/RESD quality factor (QUAL2) are shown

in Track 4. This is a gas producing well with an excellent set

of perforations, shown on the right-hand edge of Track 2.

The

conventional analysis, plotted in Track 5, gives a clear picture

of why the conventional approach is so discouraging. Unfortunately,

the laminated models do not create output curves that are consistent

with a depth plot, so it is impossible to make pretty pictures

of the results except in map form.

In

the current Milk River study, this model appears to be the

most effective in predicting reasonable reservoir properties.

PHIMAX was set at 0.20, based on core data, and KBUCKL was

set at 0.040, based on experience. CPERM and DPERM were

chosen as 18.3 and -3.00 respectively from the core data

crossplot shown earlier.

A

total of 10 reservoir quality indicators for each of 3 reservoir

layers, plus the cored interval and the perforated interval were

generated for each of 4 different analysis models. The best model

for predicting productivity is Model C, using the minimum of 3

shale indicators. The density neutron porosity separation indicator

is essential to the success of Model C.

The

best productivity indicator is the flow capacity (KH) or its equivalent

productivity estimate in e3m3 for 90 days (1st 3 months production

estimate). Five other indicators have strong correlations with

productivity (Net Reservoir, PV, HPV, Hester’s QUAL1 >=5,

and QUAL1 >=4). Hester’s number does not have much resolution

at low flow rates, but clearly separates poor from good wells.

An

important use of the summary tables is to determine whether a

well is under-achieving due to limited perforation interval or

a poor frac job. A comparison of the total KH for the Milk River

compared to the KH for the perforated interval will point out

any problem wells. Even if KH is badly mis-calibrated, the comparison

is useful. Over-achievers may be producing commingled, intentionally

or otherwise, from deeper horizons or may point to log data or

analytical difficulties.

Depth plot showing Hester quality factor in Track

4 (shaded black)

The models can be used to generate a perforation list from Hester’s

quality number or from VSH minimum. An acceptance/rejection filter on the list

will shorten it considerably. This will eliminate intervals that

are too thin to bother with and group intervals that are close

enough to be considered as single intervals.

Because

a full log suite was available in the 9 wells used for calibration,

we have obtained the most likely shale volume (Vsh) result. The

8 wells held in reserve to test the model also showed very good

agreement with initial production. One well that calculated an

IP higher than actual can be brought into line with a small tune-up

of the shale density parameter

for initial production comparison

|